A catalyst having a core-shell structure, a preparing method and uses of the catalyst

A core-shell structure, catalyst technology, applied in structural parts, nanotechnology for materials and surface science, electrical components, etc., can solve problems such as low catalytic performance, high catalyst cost, and short cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Measure 0.0168g of citric acid into a three-necked flask, add 100ml of deionized water to ultrasonically dissolve, and disperse evenly. Then weigh 0.03g of sodium borohydride and add it to this solution, and feed nitrogen gas, stir mechanically, for 10min, slowly add 100 microliters of 0.4mol / L cobalt chloride solution dropwise to the above solution, stir mechanically, and fully react 10min. Measure 3ml of 10mM sodium chloropalladate, add it quickly, continue to maintain mechanical stirring, fully react for 50min, and then centrifuge and wash to prepare a new type of palladium-cobalt "egg yolk-eggshell" structure catalyst, that is, a core-shell structure catalyst.

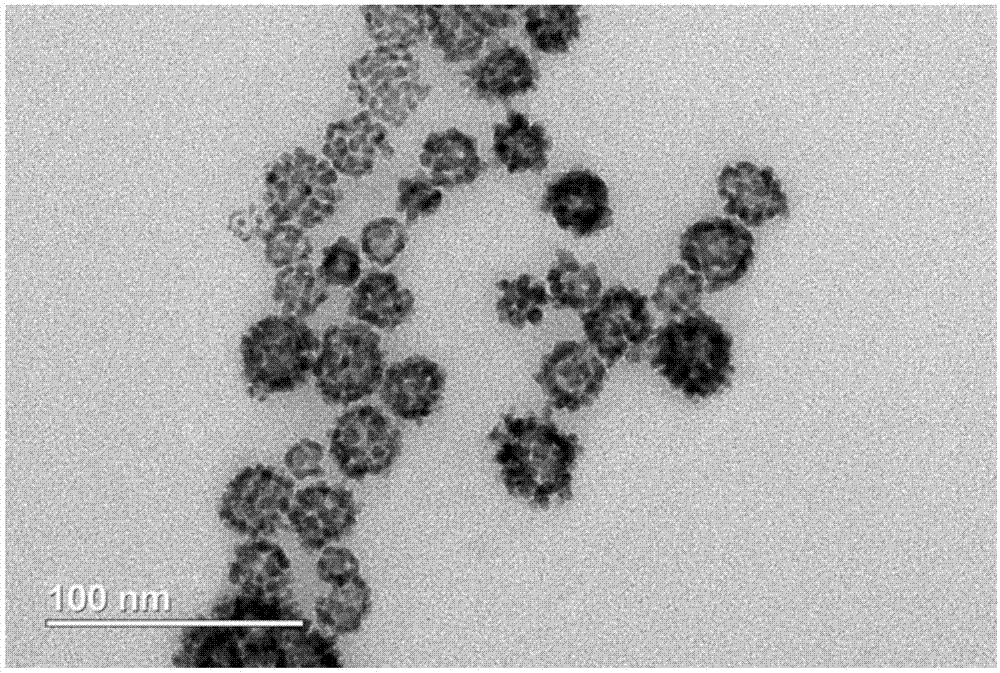

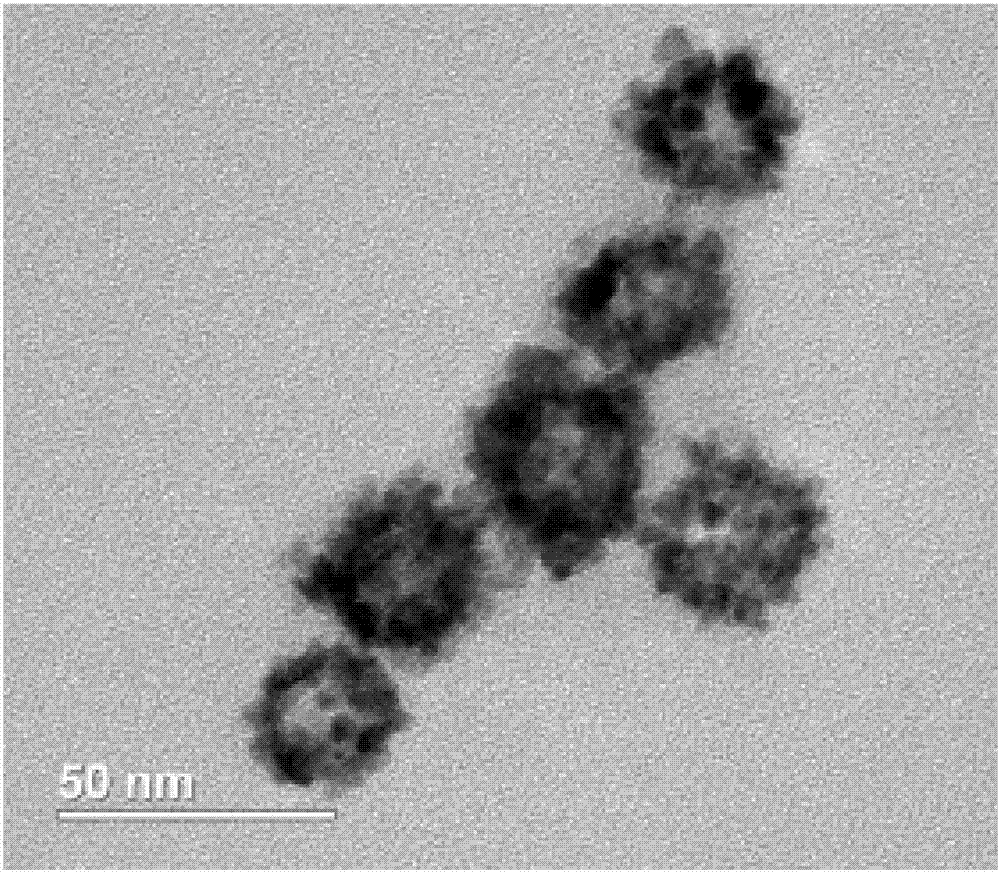

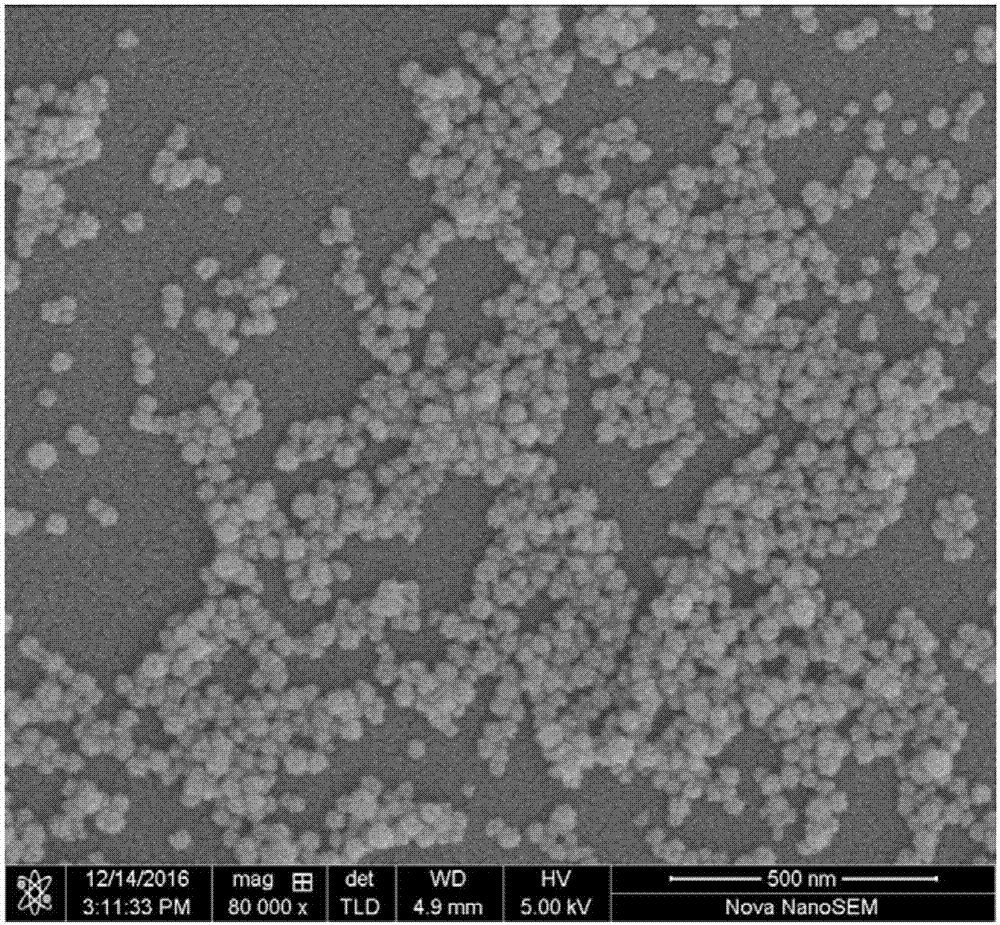

[0087] The catalyst was characterized by scanning tunneling microscope (SEM) and transmission electron microscope (TEM). Figure 1A-1B and figure 2 As shown, the prepared novel palladium-cobalt "egg yolk-eggshell" structure catalyst is a hollow porous structure, and contains cobalt nuclei inside, uniforml...

Embodiment 2

[0090] Measure 0.0168g of citric acid into a three-necked flask, add 100ml of deionized water to ultrasonically dissolve, and disperse evenly. Then weigh 0.03g of sodium borohydride and add it to this solution, and feed nitrogen gas, stir mechanically, for 10min, slowly add 100 microliters of 0.4mol / L cobalt chloride solution dropwise to the above solution, stir mechanically, and fully react 10min. Measure 2ml of 10mM sodium chloropalladate, quickly add it, continue to maintain mechanical stirring, fully react for 50min, and then centrifuge and wash to prepare a new type of palladium-cobalt "egg yolk-eggshell" structure catalyst, that is, a core-shell structure catalyst.

[0091] The catalyst was characterized by scanning tunneling microscopy (SEM), and the results were as follows: Figure 4 As shown, the prepared novel palladium-cobalt "egg yolk-eggshell" structure catalyst is a hollow porous structure, and contains cobalt nuclei inside, uniformly dispersed and uniform in si...

Embodiment 3

[0094] Measure 0.0168g of citric acid into a three-necked flask, add 100ml of deionized water to ultrasonically dissolve, and disperse evenly. Then weigh 0.03g of sodium borohydride and add it to this solution, and feed nitrogen gas, stir mechanically, for 10min, slowly add 100 microliters of 0.4mol / L cobalt chloride solution dropwise to the above solution, stir mechanically, and fully react 10min. Measure 4ml of 10mM sodium chloropalladate, add it quickly, continue to maintain mechanical stirring, fully react for 50min, and then centrifuge and wash to prepare a new palladium-cobalt "egg yolk-eggshell" structure catalyst, that is, a core-shell structure catalyst.

[0095] The catalyst was characterized by scanning tunneling microscopy (SEM), and the results were as follows: Figure 6 As shown, the prepared novel palladium-cobalt "egg yolk-eggshell" catalyst has a hollow porous structure, and contains cobalt nuclei inside, which is uniformly dispersed and uniform in size. Aro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com