Active elevator car noise control method and device

A technology of active control and elevator car, which is applied in the direction of sound-generating devices and instruments, can solve the problems of complex process, large volume, and increase the difficulty of elevator design, etc., and achieve the effect of simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides an active noise control method for an elevator car, which is suitable for noise reduction of low-frequency noise in the elevator car. The noise active control method is implemented by an elevator car noise active control device, which is implemented by software and / or hardware, and is generally integrated into the elevator car and the elevator control system.

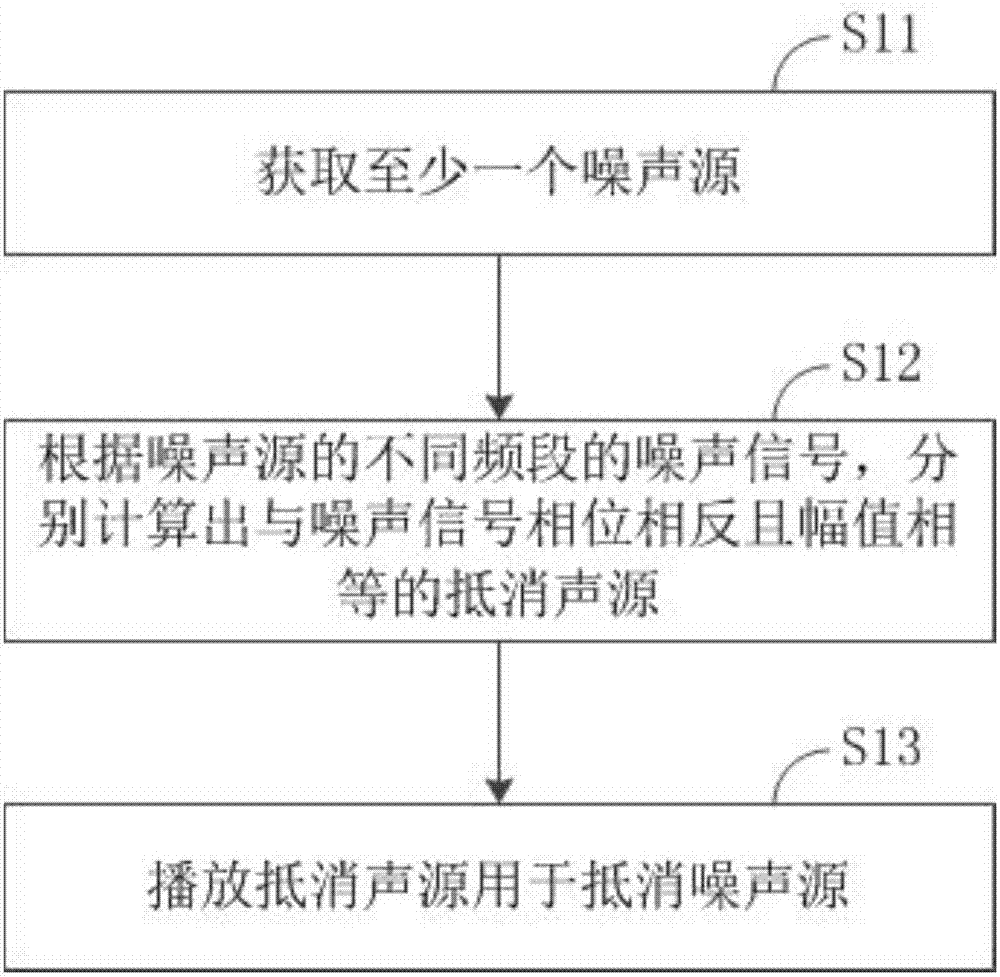

[0046] figure 1 It is a flow chart of the noise active control method of the elevator car provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the noise active control method includes the following steps:

[0047] S11. Acquire at least one noise source.

[0048] After at least one noise source is obtained, noise signals with a frequency above a preset threshold in each noise source are filtered out. The frequency of low-frequency noise is below 200 Hz, the frequency of intermediate-frequency noise is 500 Hz to 2 kHz, and the frequency of high frequency is 2 kH...

Embodiment 2

[0059] This embodiment provides an active noise control device for an elevator car, which is used to implement the methods described in the above embodiments, solve the same technical problem, and achieve the same technical effect.

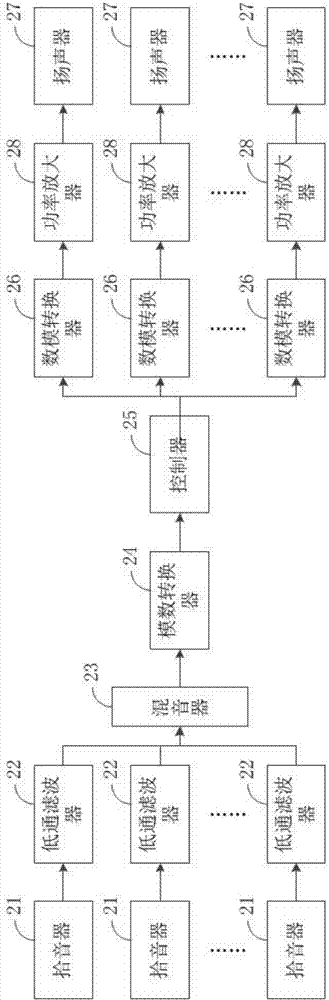

[0060] figure 2 It is a structural schematic diagram of an active noise control device for an elevator car provided by Embodiment 2 of the present invention. Such as figure 2 As shown, the active noise control device includes: a pickup 21 , an analog-to-digital converter 24 , a controller 25 , a digital-to-analog converter 26 , a power amplifier 28 and a speaker 27 .

[0061] At least one sound pickup 21 is arranged on the inner wall of the elevator car for picking up at least one noise source.

[0062] The analog-to-digital converter 24 is used to receive the input of the pickup 21 and output it to the controller 25 to convert the noise source from an analog signal to a digital signal.

[0063] The controller 25 is used for calculating the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com