Optical component debugging method and tool based on infrared imaging

A technology of optical components and debugging methods, applied in the field of installation and adjustment of various infrared optical systems, can solve the problems of tight design tolerances, inability to guarantee processing, and difficult processing of components, simplifying installation difficulties, and eliminating clamping stress. The influence of the surface shape of the test piece and the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, in conjunction with the drawings, a preferred specific example is described in detail to further illustrate the present invention.

[0054] The present invention provides a method and tool for debugging optical components based on infrared imaging, including: testing and adjusting the inclination of a tilted spherical secondary reflector; testing and adjusting the eccentricity of a plano-convex lens; controlling the verticality of the optical axis of the primary reflector; and , Detect and adjust the posture of the aspheric main reflector.

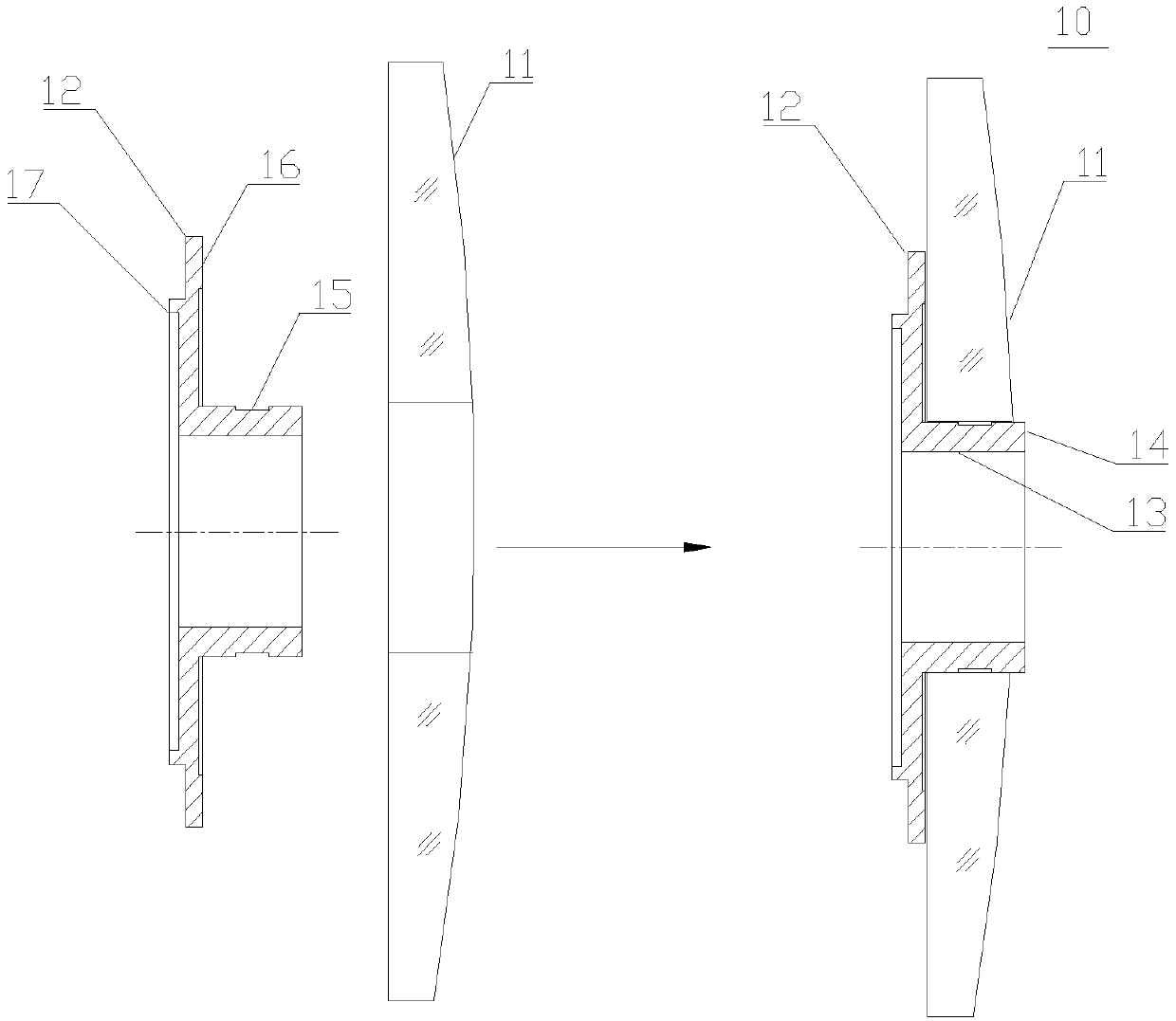

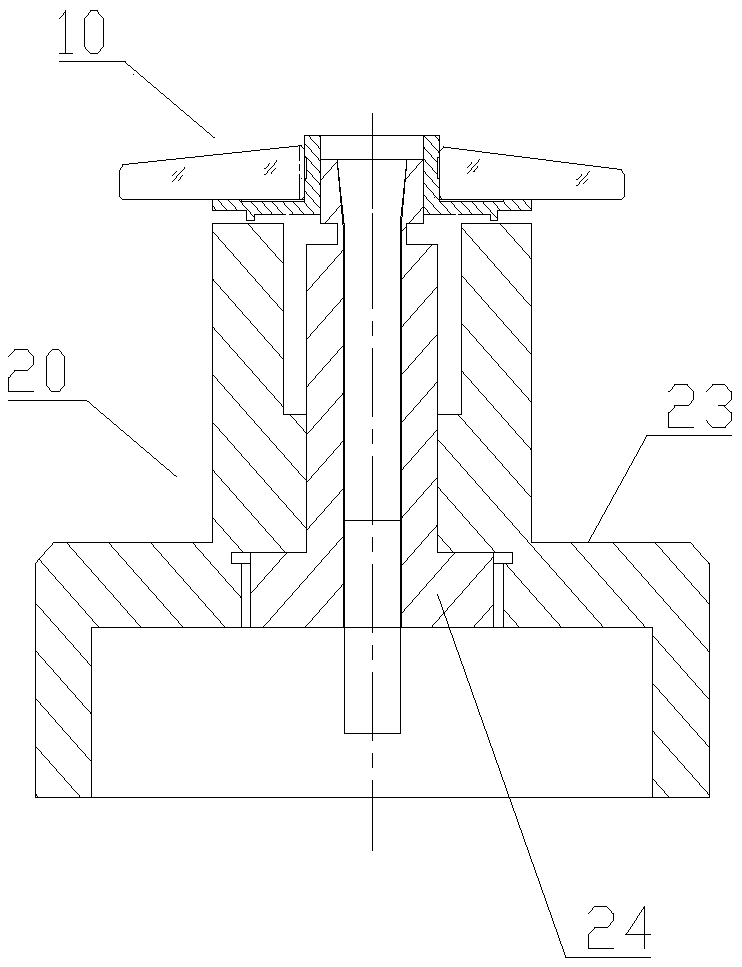

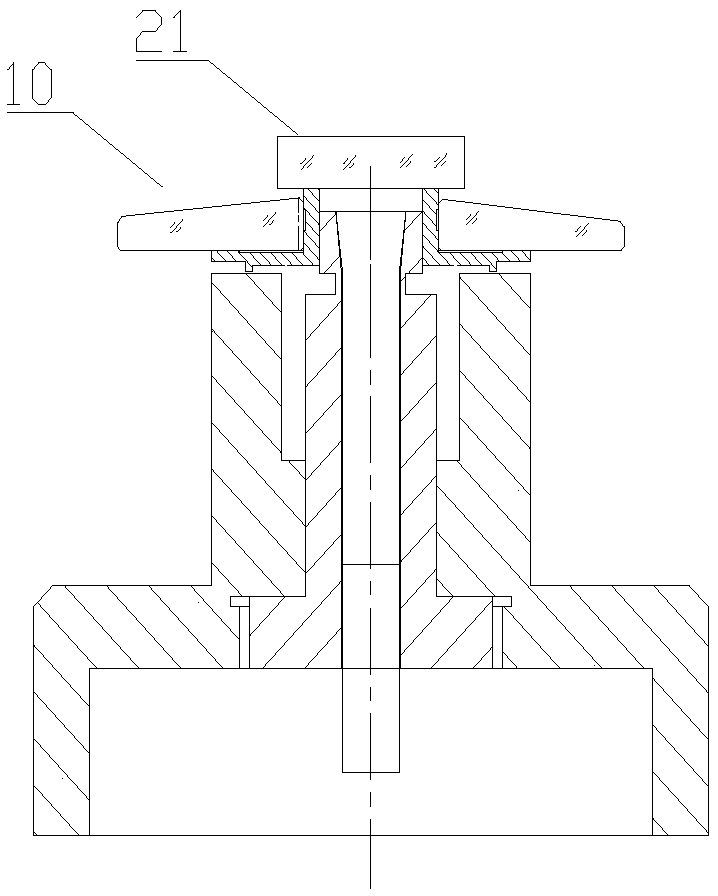

[0055] Such as Figure 1a~Figure 1d As shown, it is a schematic diagram of the step-by-step assembly of the tilted spherical secondary mirror. The secondary mirror 11 is glued on the mirror base 12 to form a component ( Figure 1a ), and then assembled on the column of the system. The through hole in the middle of the secondary mirror 11 is sleeved on the outer wall of the inner hole 13 of the mirror holder 12, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com