A high-sensitivity thin-film thermocouple sensor chip and its manufacturing method

A thermocouple sensor, thin film technology, applied in thermometers, instruments, measuring heat, etc. using directly sensitive electrical/magnetic components, can solve problems such as excessive cold junction temperature, prevent oxidation failure, enhance sensitivity, improve The effect of output sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

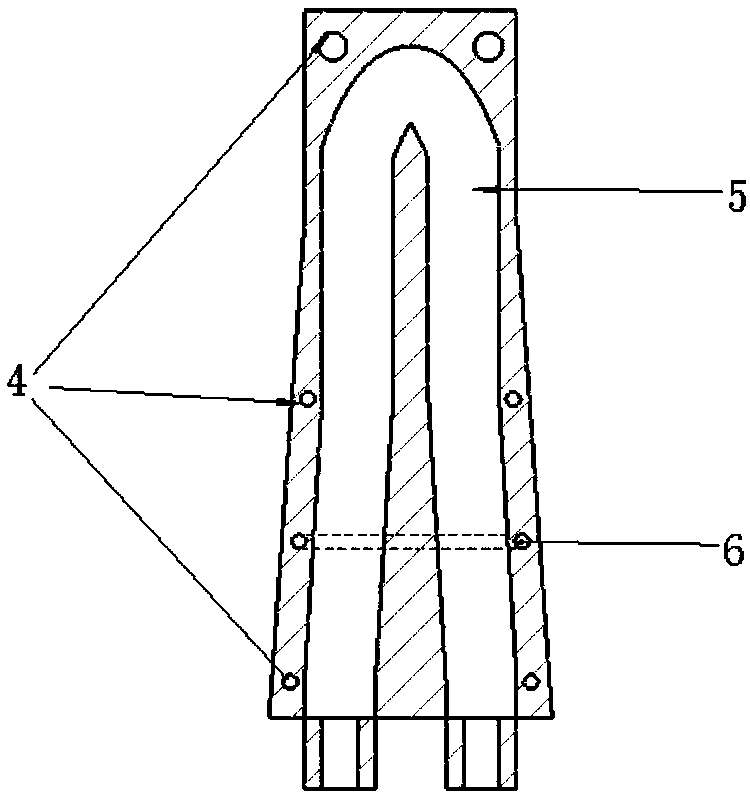

[0030] refer to figure 1 with figure 2 , a high-sensitivity thin-film thermocouple sensor chip of the present invention includes a housing, and a cavity 5 for placing an alloy thin film and an annular hole 6 for placing graphene are arranged inside the housing. The annular hole 6 is located on the outer periphery of the cavity 5 .

[0031] In the cavity 5, a U-shaped alloy film with a thickness of nanoscale is grown by atomic deposition technology to form a thin-film thermocouple, and in the annular hole 6, reinforced graphene is prepared by reduction of graphene oxide.

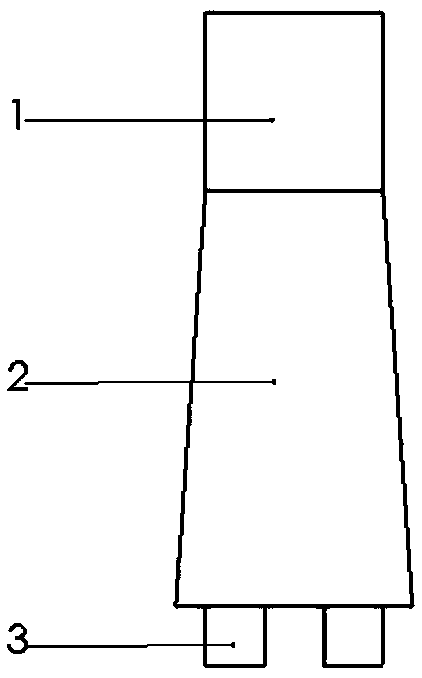

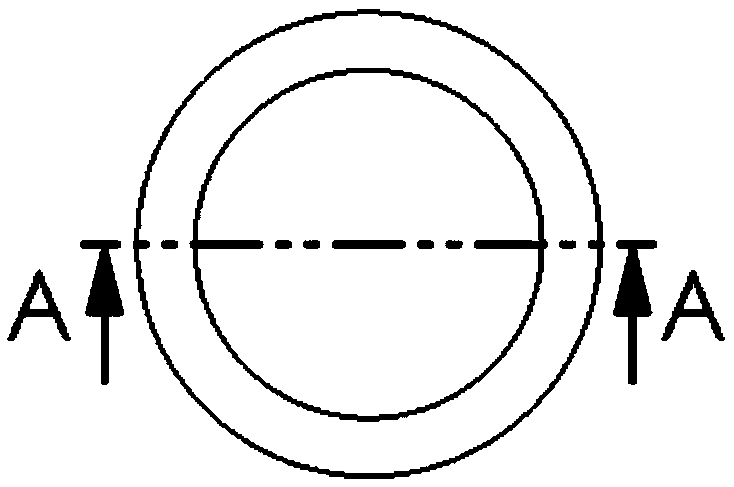

[0032] The housing includes three sections: a test probe 1, an intermediate round table 2 and a lead end 3; the outside of the test probe 1 is a cylinder with a diameter of 3 mm and a height of 3 mm. The middle circular platform 2 is a circular platform, the diameter of the upper bottom surface is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com