High-sensitivity film thermocouple sensor chip and making method thereof

A technology of thermocouple sensor and thin film, which is applied in the direction of thermometers, instruments, scientific instruments, etc. that use electric/magnetic elements that are directly sensitive to heat. Effect of Output Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings:

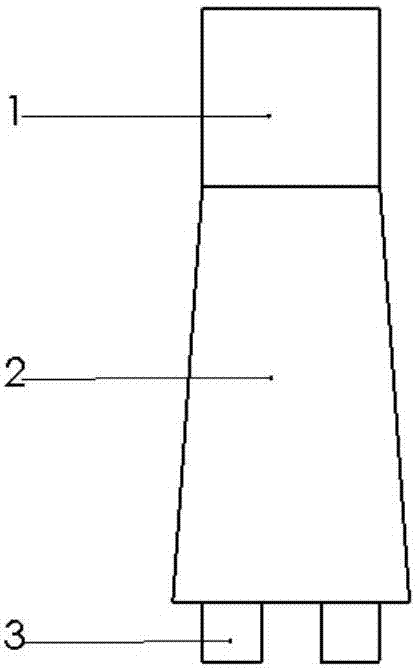

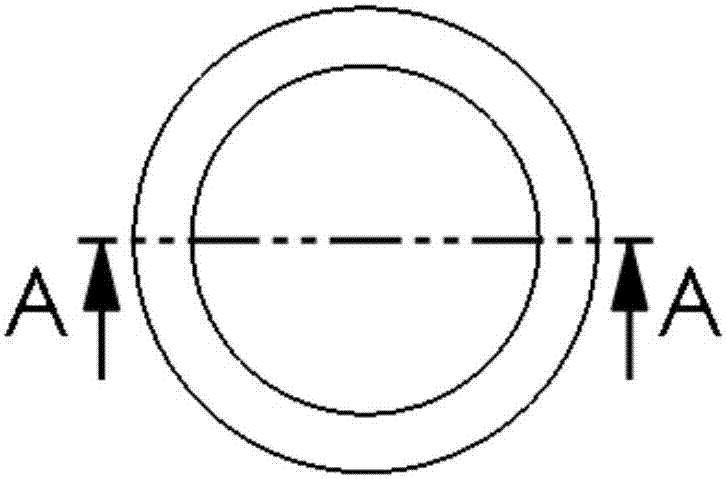

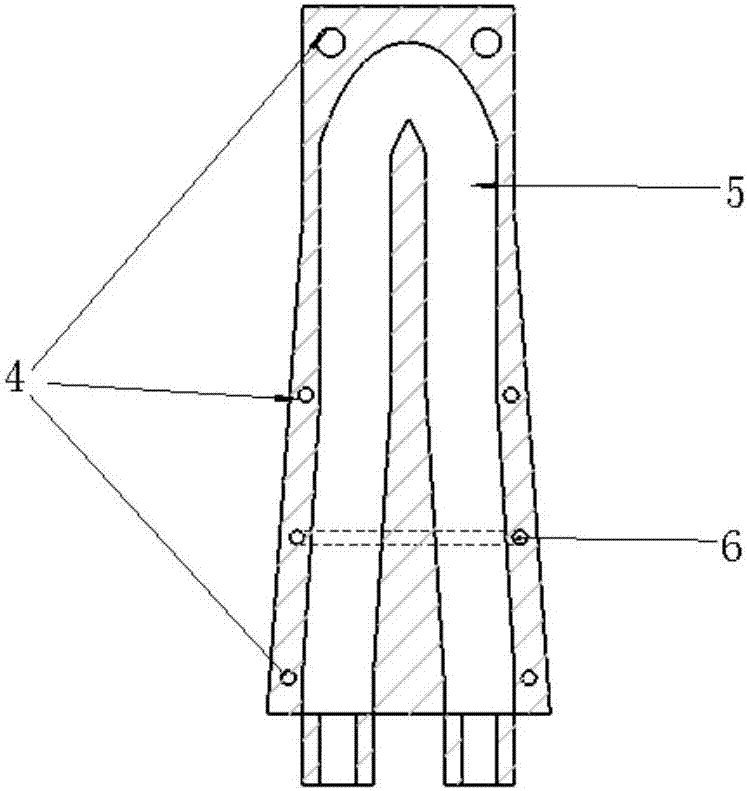

[0030] Reference figure 1 with figure 2 , A high-sensitivity thin-film thermocouple sensor chip of the present invention includes a housing, and a cavity 5 for placing an alloy film and an annular hole 6 for placing graphene are arranged inside the housing. The annular hole 6 is located on the outer periphery of the cavity 5.

[0031] A layer of U-shaped nano-thickness alloy film is grown in the cavity 5 to form a thin-film thermocouple, and the ring hole 6 is reduced by graphene oxide to prepare enhanced graphene.

[0032] The shell includes three sections: the test probe 1, the middle round table 2 and the lead end 3. The outside of the test probe 1 is a cylinder with a diameter of 3mm and a height of 3mm. The middle round table 2 is a round table with an upper bottom surface of 3mm in diameter and a lower bottom surface of 4mm in diameter, forming a certain tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com