An intelligent system and method for preventing combustible gas deflagration at the furnace bottom

An intelligent, gas technology, applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of economic loss outweighing the gains, the increase of the desuperheater and reheater desuperheating water, the upward movement of the boiler flame center, etc. The effect of less construction work, low investment cost and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

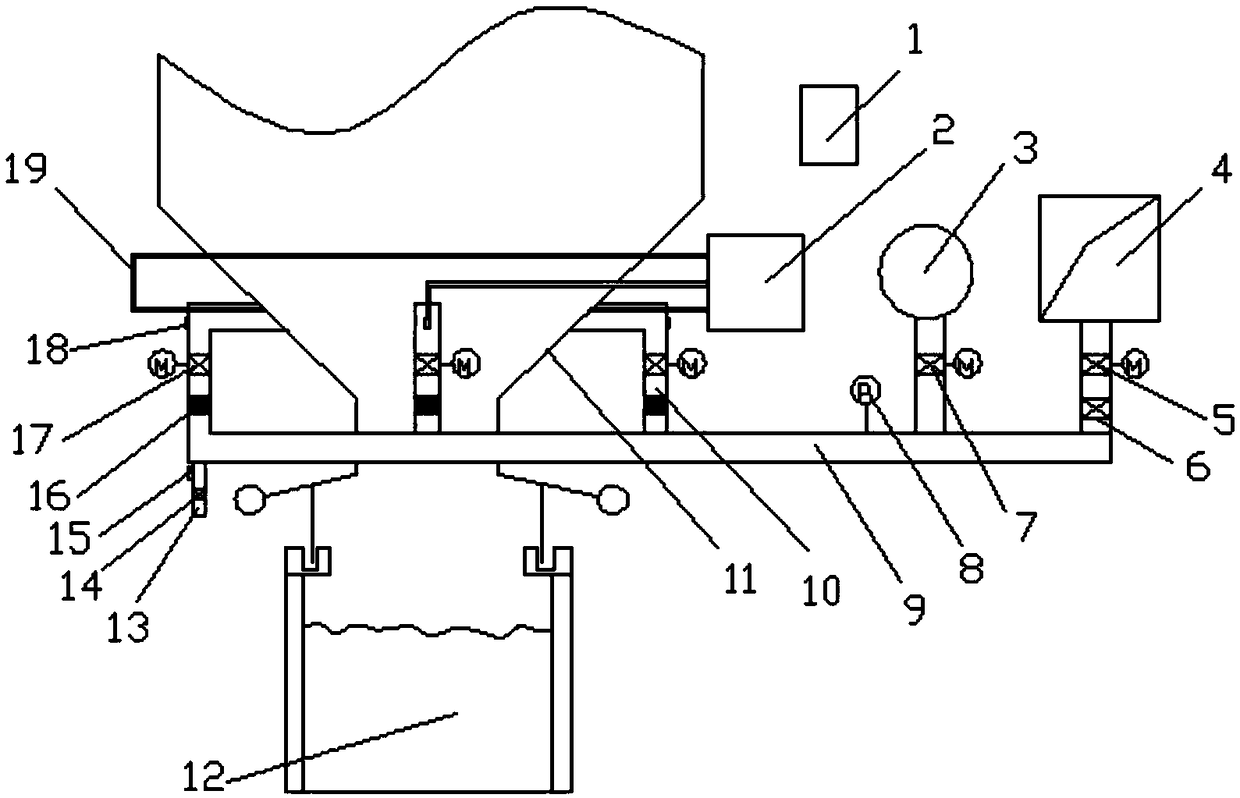

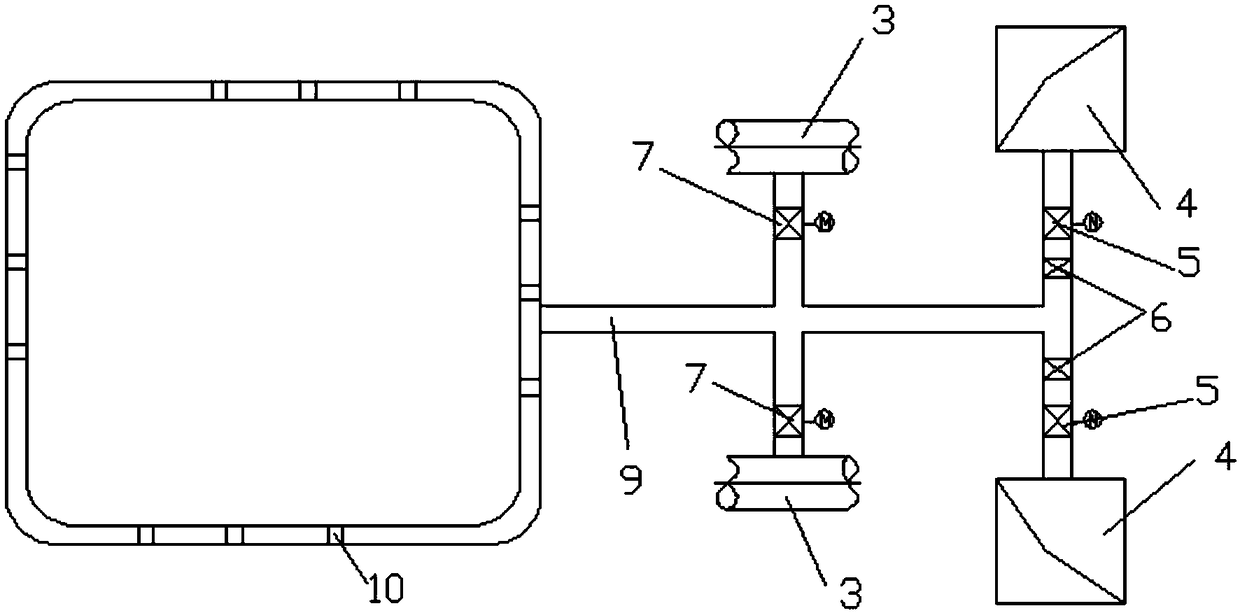

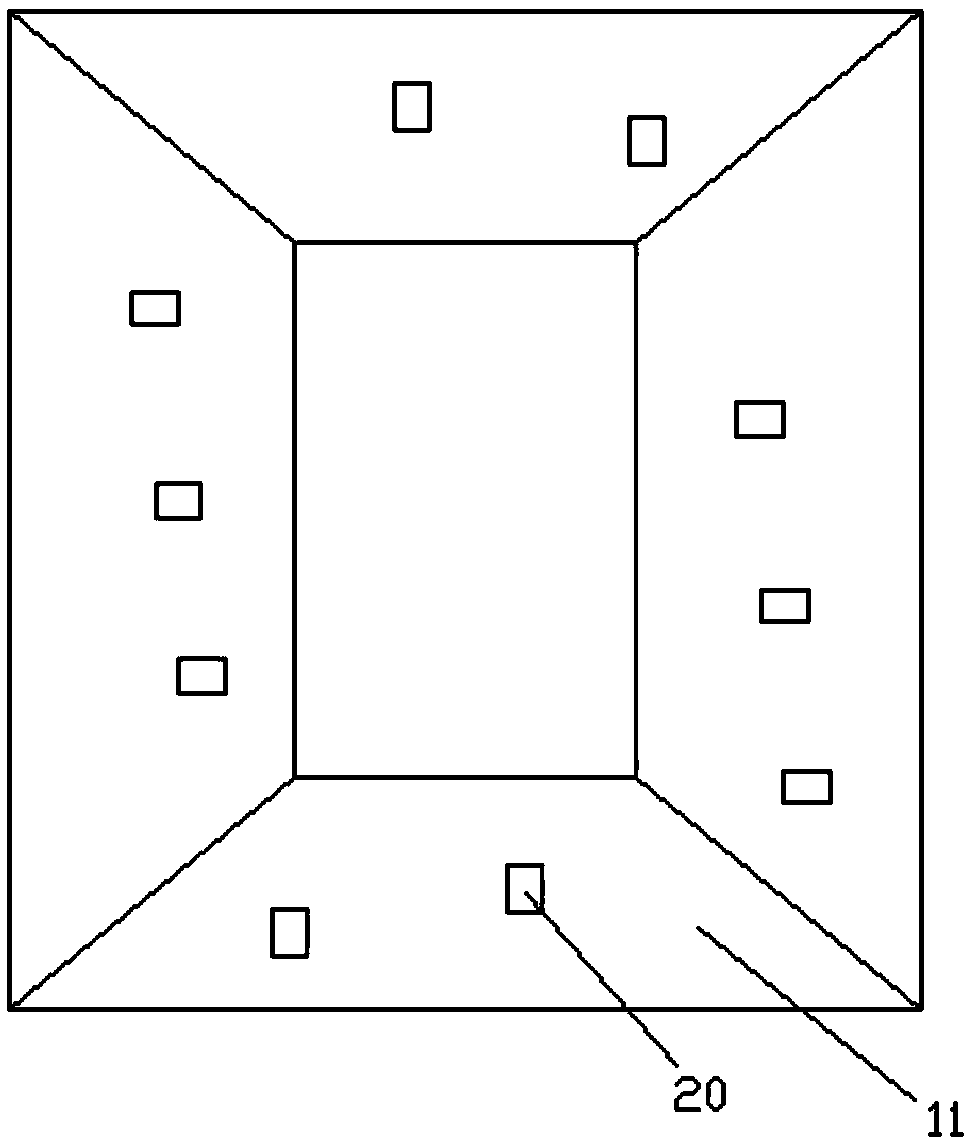

[0058] Boiler #4 of a power plant of Huadian Group is a subcritical, intermediate reheating, forced circulation drum boiler with an evaporation capacity of 1025t / h. The combustion method is a four-corner tangential combustion method. Blowing pulverizing system, solid slag discharge, open-air structure layout. The original burner of this boiler adopts the enhanced combustion technology of CE Company in the United States, and the concentration of nitrogen oxides is high. After the transformation of the nitrogen burner, the nitrogen oxide emission concentration of the boiler dropped significantly, but the furnace pressure often fluctuated greatly. After field testing, it was found that the concentration of carbon monoxide in some parts of the furnace bottom was as high as 15%. The analysis showed that the furnace bottom was combustible. Gas accumulation and deflagration caused large fluctuations in furnace pressure. After various investigations and demonstrations, an intelligent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com