Climate hall for vehicle testing

A vehicle, hall technology, applied in the field of vehicle testing facilities, which can solve the problems of expensive production, reduce the risk of damage, eliminate the formation of ice on the roof, and eliminate the accumulation of snow clumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

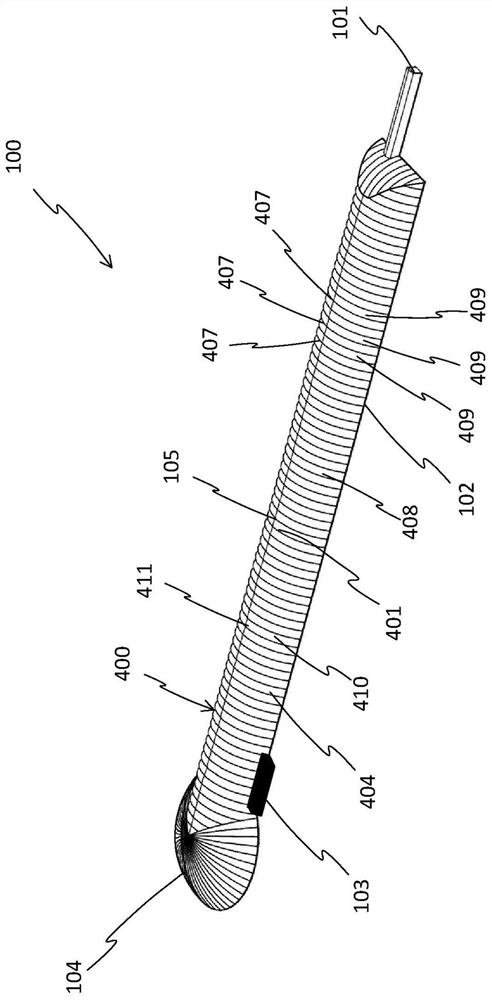

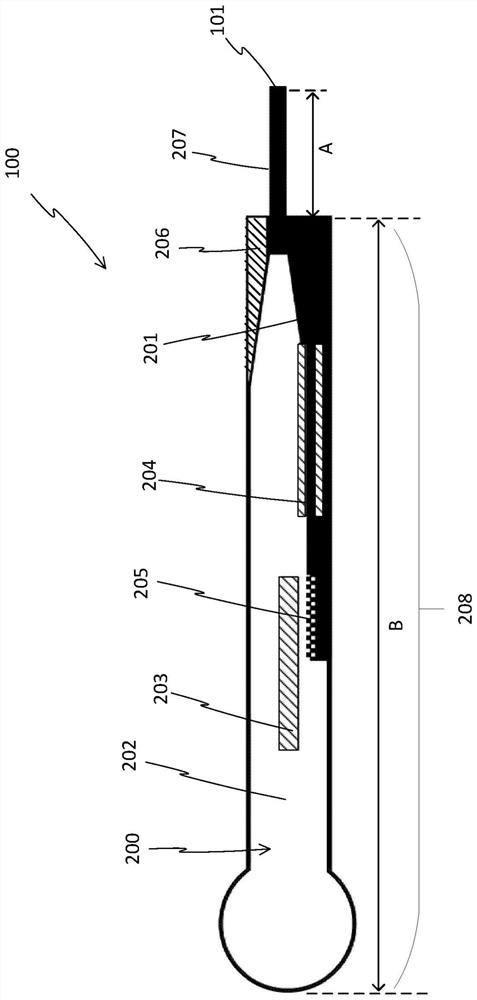

[0038] figure 1 An external view of a climate hall 100 for vehicle testing according to an embodiment of the invention is shown.

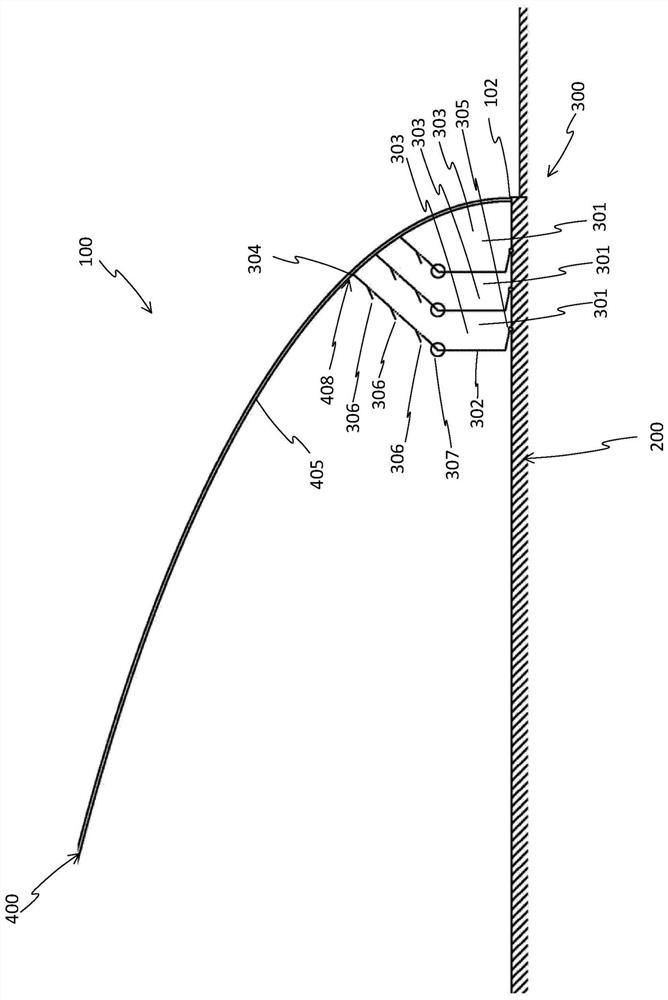

[0039] The climate hall 100 in its broadest form comprises a foundation 102 to which a flexible wall arrangement 400 is attached. The flexible wall arrangement 400 extends along the foundation 102 and is sealingly engaged thereto. The climate hall 100 further comprises a ventilation device 103 . The ventilator 103 is configured to establish an overpressure within the flexible wall arrangement 400, thereby causing the flexible wall arrangement 400 to erect to form a hall having an interior volume at least partially defined by an inner side wall portion 408 and a ceiling portion 401 which Wall and ceiling sections are formed by said flexible wall arrangement 400 . Ventilation device 103 is further configured to establish a controlled climate within the hall, forming climate hall 100 .

[0040] Such as figure 1 As shown in , in this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com