Automatic orchard variation spraying machine based on laser scanning technique

A laser scanning, automatic variable technology, applied in the field of sprayer, orchard automatic variable sprayer, can solve the problems of poor adaptability of fruit trees, low degree of automation, uneven deposition, etc., to achieve good applicability, improve working time, and good adjustment function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

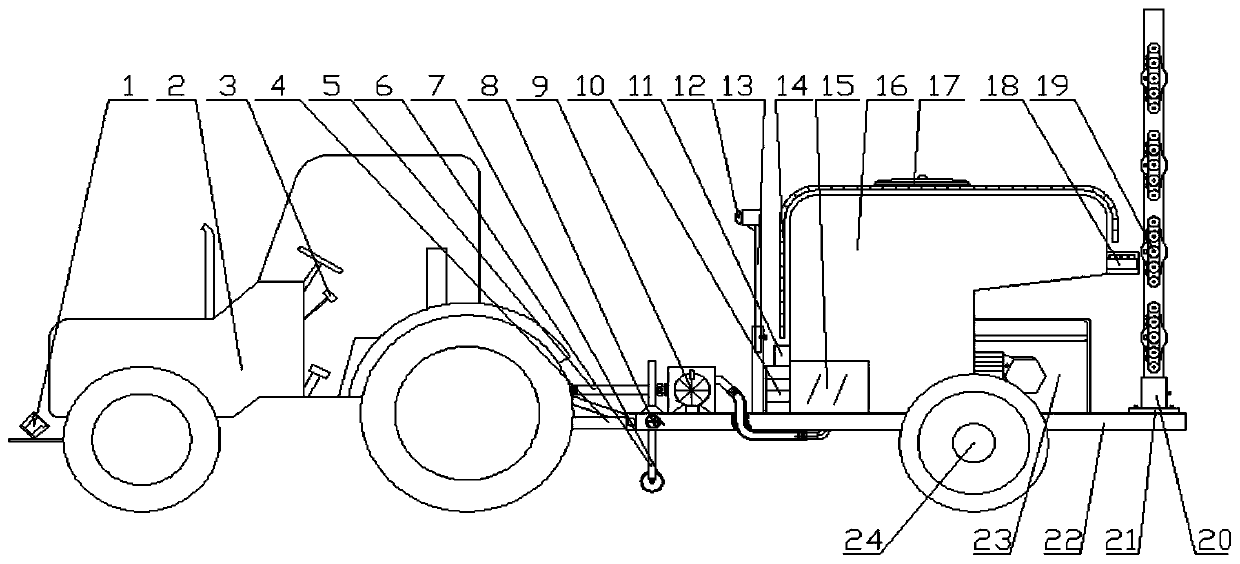

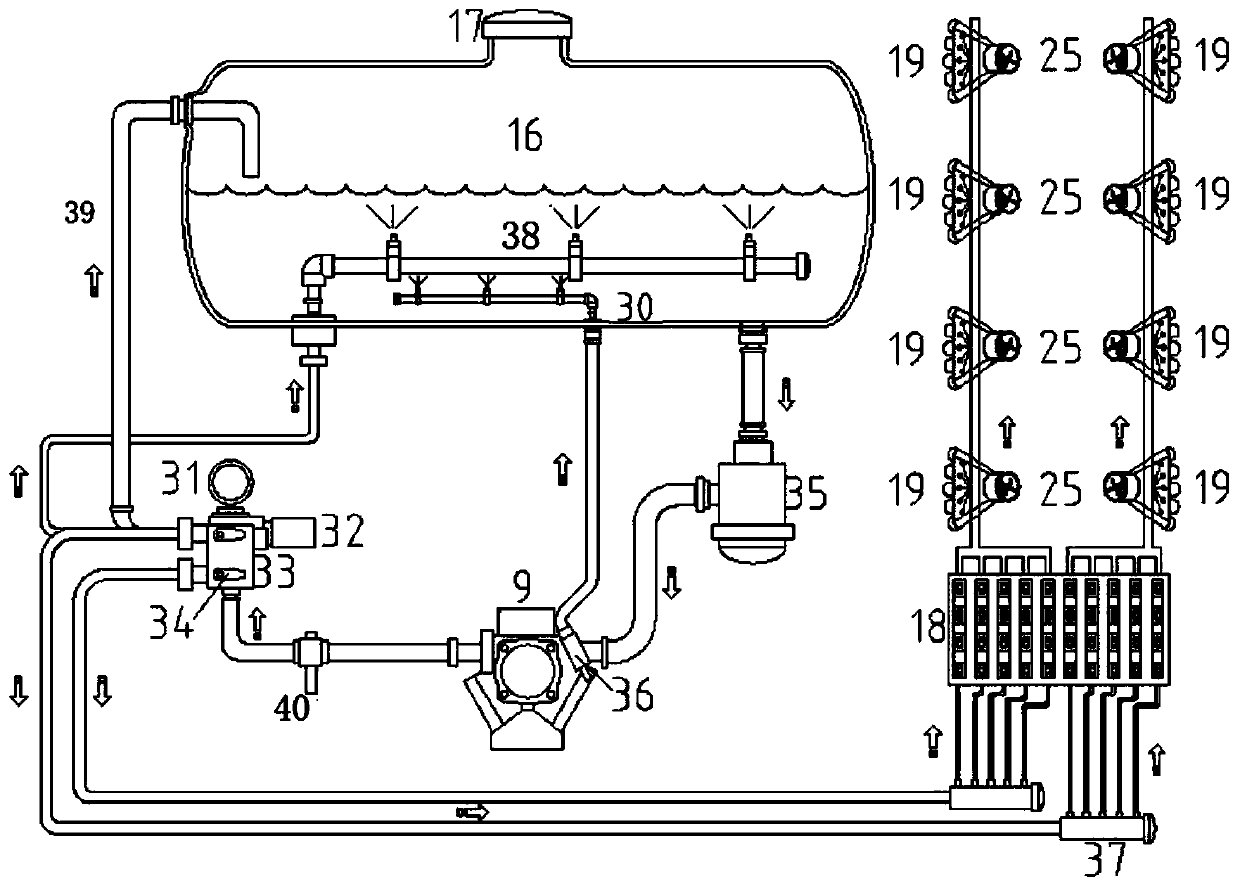

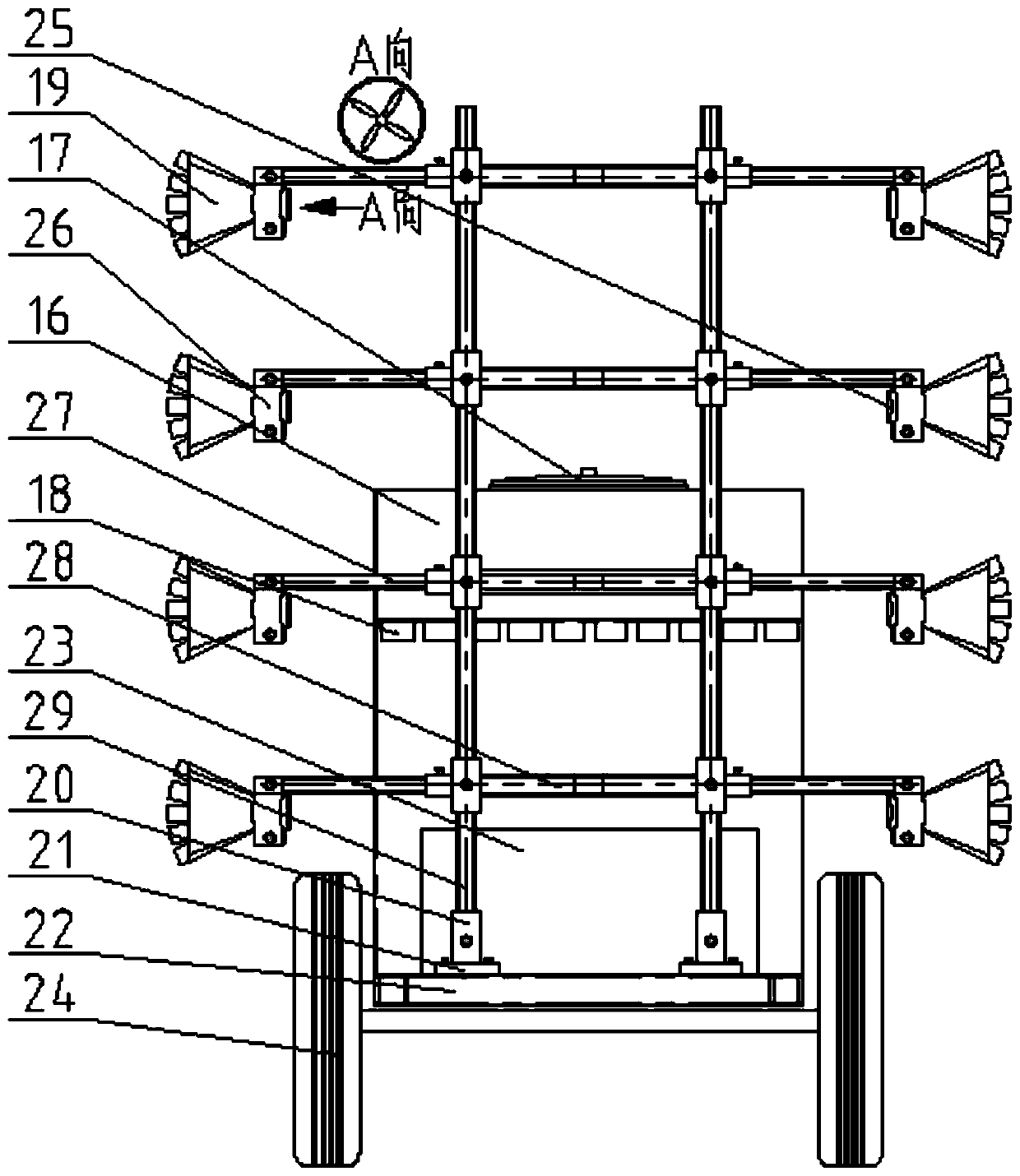

[0060] Such as figure 1 As shown, an automatic variable sprayer for orchards based on laser scanning technology is towed by a drawbar 4 provided at the rear of the tractor 2. The sprayer includes a traction chassis 22, a laser scanning detection device, a variable sprayer, an adjustable sprayer Rod devices, signal control devices and power supply devices, of which:

[0061] The traction chassis 22 is a wheeled structure, and its front and middle parts are respectively provided with guide wheels 7 and traveling wheels 24 . The guide wheel 7 is provided with a screw lifter 6, and the screw lifter 6 includes a screw adjusting handwheel 8 for adjusting the height of the lifter. The height of lifter 6, and then regulate the height of guide wheel 7.

[0062] The laser scanning detection device includes a support rod 13 vertically arranged on the front of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com