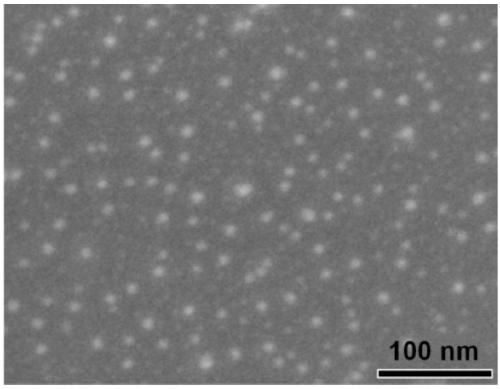

Electron irradiation preparation method of aluminum oxide quantum dots on a film surface

An electron irradiation, alumina technology, applied in ion implantation plating, metal material coating process, vacuum evaporation plating, etc. Small sample size, etc., to achieve the effect of good uniformity of morphological distribution, uniform size and good circularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment 1, the electron irradiation preparation method of the aluminum oxide quantum dots on the surface of a film is prepared sequentially according to the aforementioned process steps; the electron irradiation of the accelerator adopts a commercial electron electrostatic accelerator, a commercial electron electrostatic accelerator The model is JJ-2MV; the magnetron sputtering coating machine used is QX-500 magnetron sputtering coating machine; the heating furnace used is a box-type heating furnace, and the substrate is a single crystal silicon wafer.

[0034] A method for preparing electron irradiation of aluminum oxide quantum dots on the surface of the film described in Example 1, specifically adopts the following process steps in sequence:

[0035] Step (1), cleaning of the substrate

[0036] Firstly, the surface-polished single-crystal silicon wafers are sequentially cleaned with analytically pure nitric acid, acetone, absolute ethanol and deionized water...

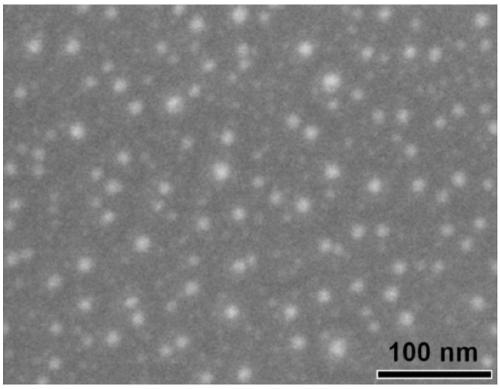

Embodiment 2

[0046] The preparation method, process steps and electron irradiation apparatus used in this embodiment 2 are the same as in embodiment 1, wherein the process parameters are different, and the substrate is a glass sheet; specifically, the following process steps are adopted successively:

[0047] Step (1), cleaning of the substrate

[0048] Firstly, the surface-polished glass sheet is sequentially cleaned with analytically pure nitric acid, acetone, absolute ethanol and deionized water in an ultrasonic tank for impurity removal, oil removal and decontamination for 20 minutes, and then dried in an oven; Subsequently, the glass sheet was put into a QX-500 magnetron sputtering coating machine for plasma backsputter cleaning. The backsplash cleaning process parameters were: the background vacuum degree was 5×10 -5 Pa, the backsplash cleaning bias is -500V, Ar gas with a purity of 99.95% is used as the working gas, the backsplash pressure is 5.0Pa, and the cleaning time is 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com