Iron-based amorphous alloy and preparation method thereof

An iron-based amorphous alloy, atomic percentage technology, used in manufacturing tools, heat treatment equipment, magnetic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

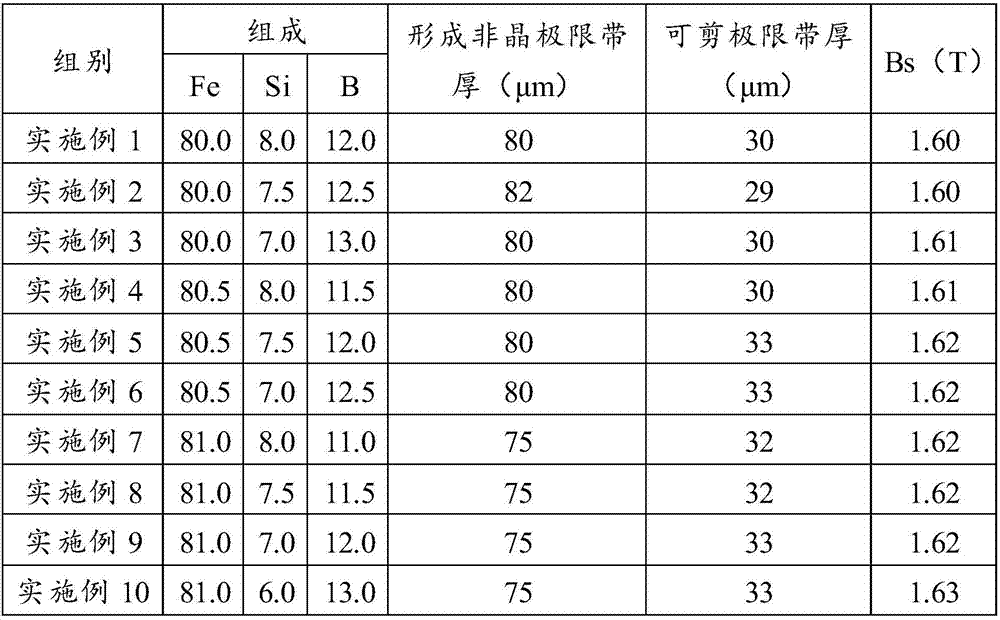

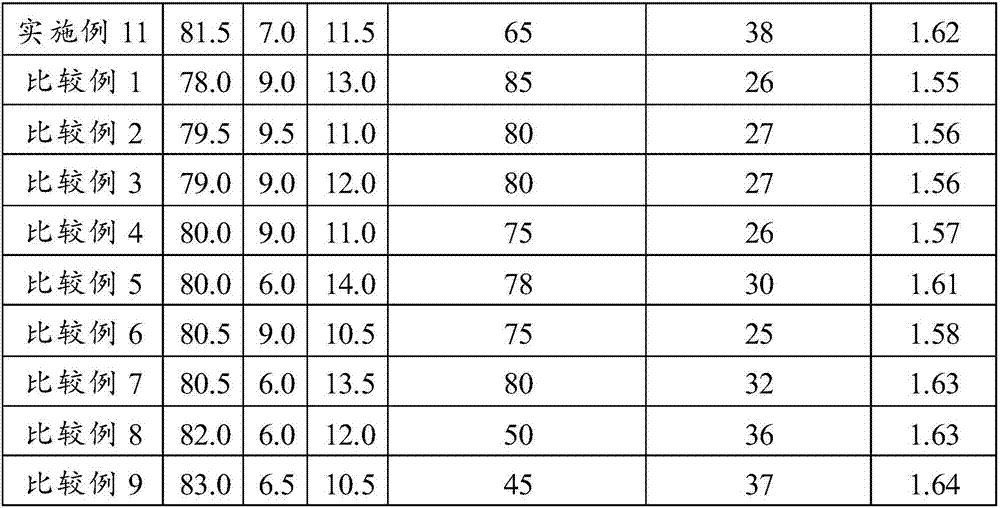

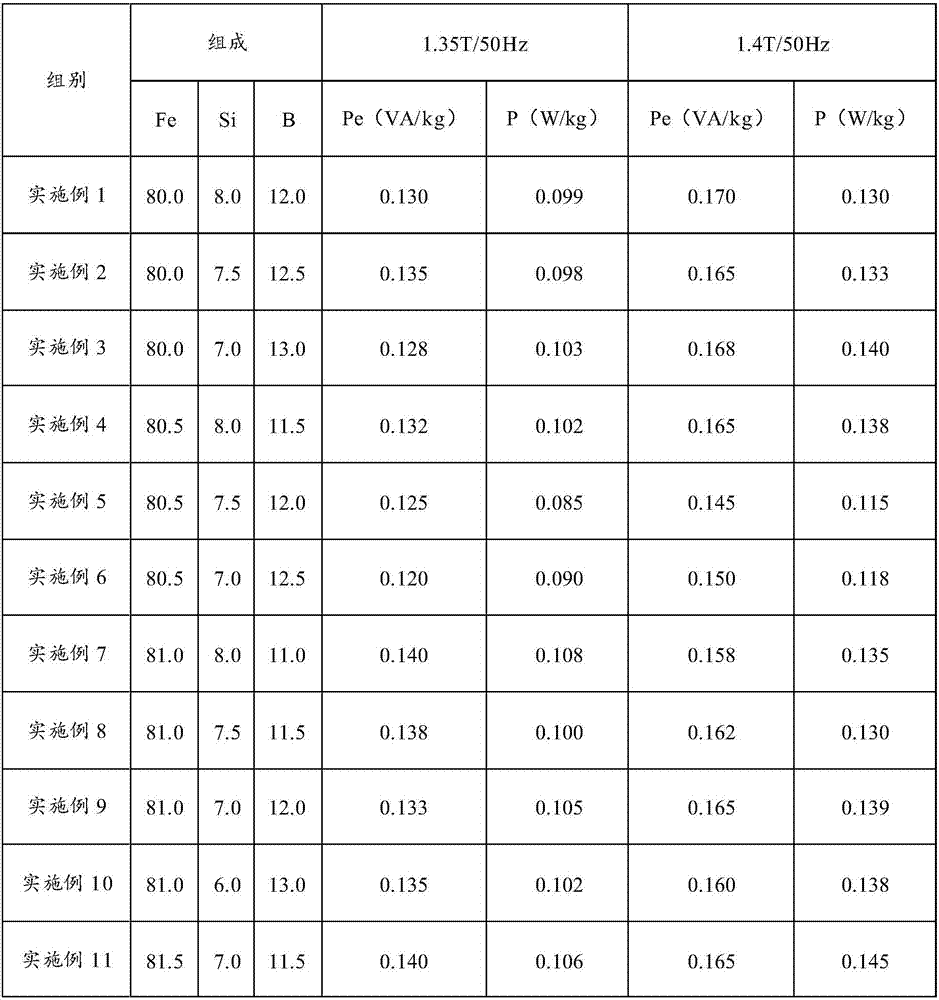

Examples

preparation example Construction

[0039] The present application also provides a method for preparing the above-mentioned iron-based amorphous alloy, comprising the following steps:

[0040] According to the formula Fe a B b Si c The atomic percentage of the iron-based amorphous alloy is batched, the batched raw materials are smelted, the temperature of the smelted melt is kept warm, and then single-roll rapid quenching is adopted to obtain the iron-based amorphous alloy strip.

[0041] In the process of preparing the iron-based amorphous alloy, the present application adopts conventional technical means in the field to prepare the iron-based amorphous alloy with the specific composition of the present application. For its preparation method, the process of batching and smelting, the present application does not specifically describe its specific operating means. During the smelting process, an intermediate frequency smelting furnace is used to smelt the metal raw material, the temperature of the smelting i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com