Processing method for 220BH cold-rolled bake-hardened high-strength steel used for automobiles

A technology of bake hardening and processing method, applied in the fields of metallurgical materials and advanced high-strength steel for automobiles, can solve problems such as environmental pollution and traffic congestion, and achieve the effect of stabilizing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The chemical composition (mass fraction / %) of this embodiment is as follows: C 0.00215; Si 0.010; Mn 0.50; P 0.050; S 0.007; Als 0.038; Nb 0.013; Cr 0.066;

[0055] In this embodiment, the heating temperature of the hot-rolled slab is 1180° C., the finish rolling temperature is 900° C., the coiling temperature is 700° C.; the cold rolling reduction is 85%.

[0056] The continuous annealing process of this embodiment is as follows: hold at 850°C for 80 minutes; cool with the furnace to 730°C, and rapidly cool to 400°C at a cooling rate of 30°C / s, hold for 2 hours, and then cool with the furnace to room temperature.

[0057] The performance index of the present embodiment is as follows: Yield strength 236MPa; Tensile strength 345MPa; Elongation 38%; 90 value 0.21; r 90 Value 2.4; BH 2 Value 55.

Embodiment 2

[0059] The chemical composition (mass fraction / %) of this embodiment is as follows: C 0.0016; Si 0.003; Mn 0.42; P 0.040; S 0.005; Als 0.028; Nb 0.016; Cr 0.058;

[0060] In this embodiment, the heating temperature of the hot-rolled slab is 1210° C., the finish rolling temperature is 900° C., the coiling temperature is 710° C.; the cold rolling reduction is 80%.

[0061] The continuous annealing process of the present invention is as follows: heat preservation at 840°C for 90 minutes; cooling to 720°C with the furnace, and rapid cooling to 400°C at a cooling rate of 35°C / s, heat preservation for 3 hours, and cooling to room temperature with the furnace.

[0062] The performance index of the present embodiment is as follows: yield strength 205MPa; Tensile strength 358MPa; Elongation 43%; n 90 value 0.23; r 90 Value 1.88; BH 2 Value 35.

Embodiment 3

[0064] The chemical composition (mass fraction / %) of this embodiment is as follows: C 0.0025; Si 0.03; Mn 0.55; P 0.060; S 0.009; Als 0.038; Nb 0.018; Cr 0.071;

[0065] In this embodiment, the heating temperature of the hot-rolled slab is 1190° C., the finish rolling temperature is 900° C., the coiling temperature is 690° C.; the cold rolling reduction is 90%.

[0066] The continuous annealing process of the present invention is as follows: heat preservation at 860°C for 70 minutes; cooling to 740°C with the furnace, and rapid cooling to 400°C at a cooling rate of 40°C / s, heat preservation for 2 hours, and cooling to room temperature with the furnace.

[0067] The performance index of the present embodiment is as follows: yield strength 215MPa; Tensile strength 352MPa; Elongation 46.5%; n 90 value 0.24; r 90 Value 2.54; BH 2 Value 48.

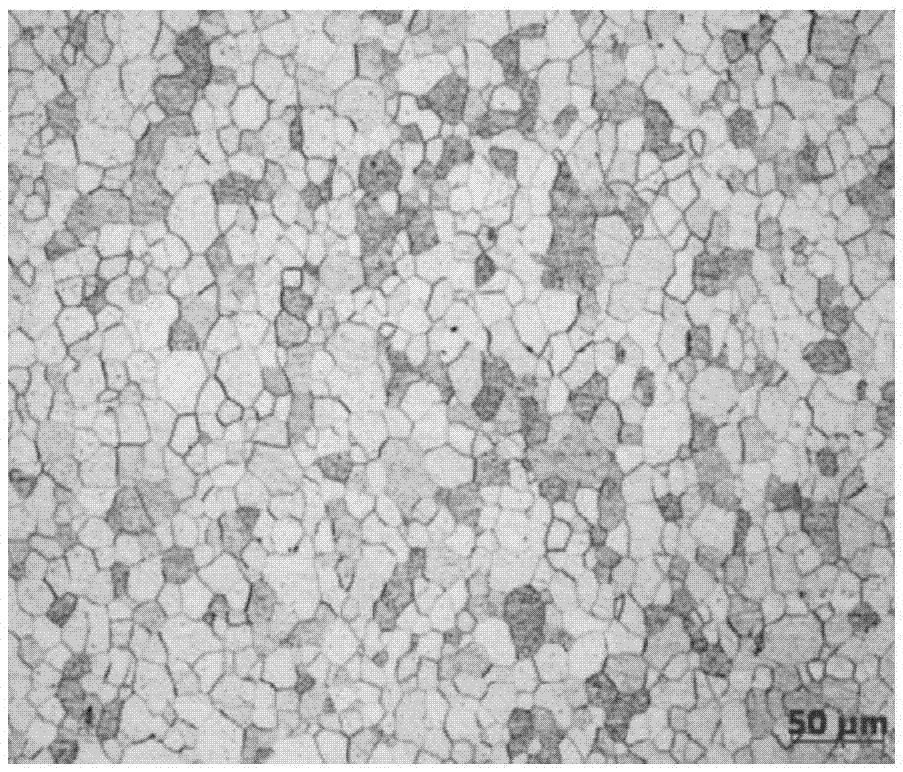

[0068] Such as figure 1 As shown in Table 1, the finished structure of cold-rolled bake-hardening high-strength high-strength steel 220BH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com