Method for preparing iminodiacetic acid through continuous hydrolysis and self-oscillating reactor

A technology of iminodiacetic acid and iminodiacetonitrile, which is applied in the field of self-oscillating reactors and continuous hydrolysis to prepare iminodiacetic acid, can solve the problems of low reaction efficiency and long residence time, and achieve improved reaction rate, Effect of reduced water consumption, good reaction and temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

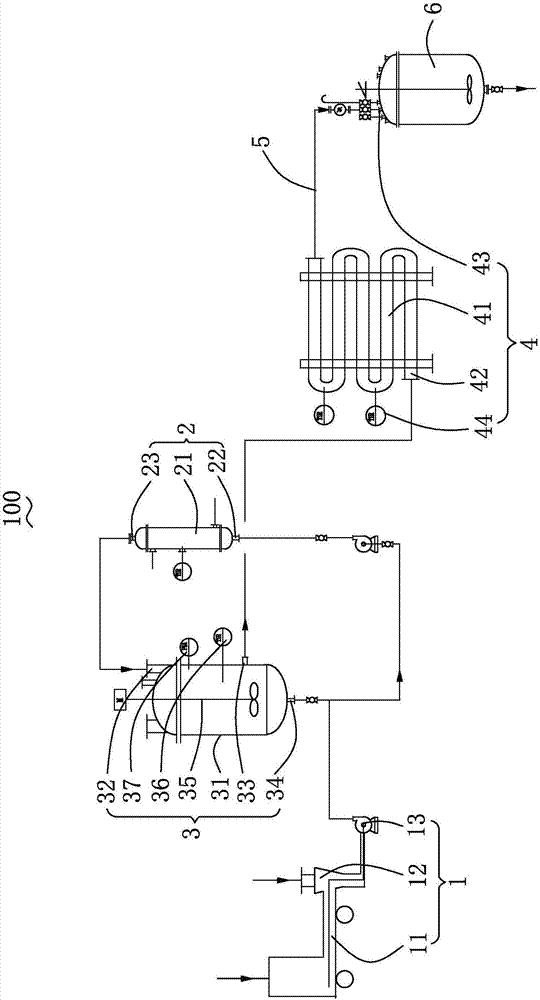

[0045] A method for preparing iminodiacetic acid by continuous hydrolysis, comprising the steps of:

[0046] Step S1: mixing the reaction material iminodiacetonitrile and water according to the molar ratio of 1:5;

[0047] Specifically, the raw material iminodiacetonitrile is transported to the solid-liquid mixing device 12 through the metering screw 11; the raw material water is also transported to the solid-liquid mixing device 12, and the two are mixed in proportion;

[0048] Step S2: transporting the mixed material to the fully mixed reactor 3 for hydrolysis;

[0049] Specifically, the material delivery pump 13 transports the mixed material to the heat exchanger 2 to heat the reaction material, and after heating, the reaction material enters the fully mixed reactor 3 through the second feed port 32; And control the reaction temperature in the fully mixed reactor 3 to be 190°C, and the reaction pressure to be 9MPa;

[0050] Step S3: the reaction liquid in the fully mixed ...

Embodiment 2

[0056] A method for preparing iminodiacetic acid by continuous hydrolysis, comprising the steps of:

[0057] Step S1: mixing the reaction material iminodiacetonitrile and water according to the molar ratio of 1:10;

[0058] Step S2: transporting the mixed material to the fully mixed reactor 3 for hydrolysis;

[0059] Specifically, the material delivery pump 13 transports the mixed material to the heat exchanger 2 to heat the reaction material, and after heating, the reaction material enters the fully mixed reactor 3 through the second feed port 32; Control the reaction temperature to 195°C and the reaction pressure to 10MPa;

[0060] Step S3: the reaction liquid in the fully mixed reactor 3 flows into the tubular reactor 4 under the action of liquid head pressure;

[0061] Specifically, when the materials in the full-mixing reactor 3 have reacted to a certain extent, the materials flow out from the second discharge port 33 under the action of the pressure difference, and ent...

Embodiment 3

[0065] A method for preparing iminodiacetic acid by continuous hydrolysis, comprising the steps of:

[0066] Step S1: mixing the reaction raw material iminodiacetonitrile and water according to the molar ratio of 1:20;

[0067] Step S2: transporting the mixed material to the fully mixed reactor 3 for hydrolysis;

[0068] Specifically, the material delivery pump 13 transports the mixed material to the heat exchanger 2 to heat the reaction material, and after heating, the reaction material enters the fully mixed reactor 3 through the second feed port 32; Control the reaction temperature to 200°C and the reaction pressure to 11MPa;

[0069] Step S3: the reaction liquid in the fully mixed reactor 3 flows into the tubular reactor 4 under the action of liquid head pressure;

[0070] Specifically, when the materials in the full-mixing reactor 3 have reacted to a certain extent, the materials flow out from the second discharge port 33 under the action of the pressure difference, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com