Detection tool clamp

A technology for detecting tooling and fixtures, which is applied in the field of mechanical processing, can solve problems such as artificial mixing, decreased accuracy of machine tools, hidden dangers to personal safety, etc., and achieve the effect of preventing artificial mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

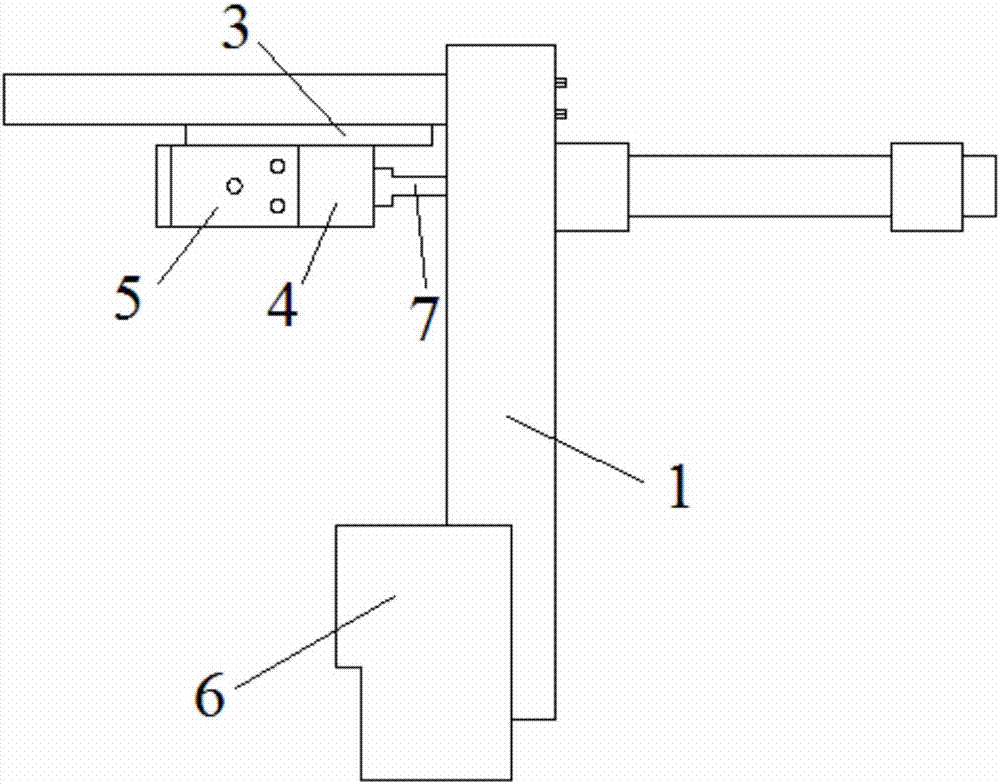

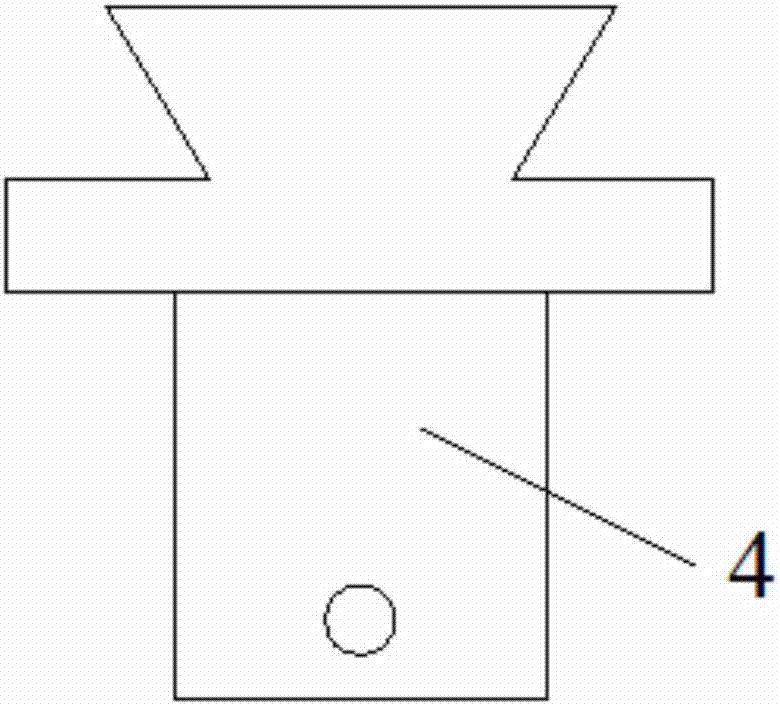

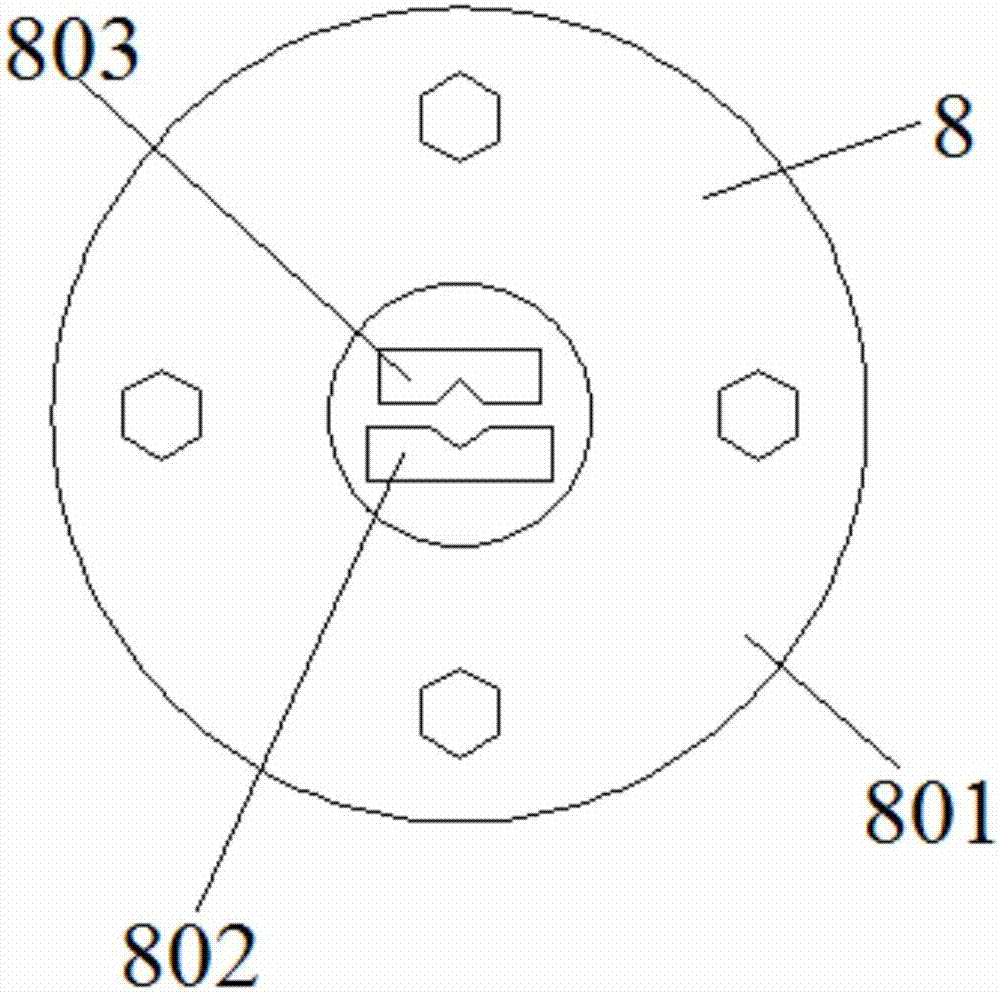

[0051] figure 1 It shows a schematic diagram of an inspection tooling fixture according to an embodiment of the present invention. figure 2 A schematic diagram of a dovetail slider according to an embodiment of the present invention is shown. image 3 A schematic diagram of a V-shaped clamp according to an embodiment of the present invention is shown.

[0052] Such as Figure 1-3 As shown, the testing fixture includes:

[0053] Install the adjustment board 1. There are slide rails 2 on both sides of the installation adjustment board 1;

[0054] Dovetail chute 3, dovetail chute 3 is slidably arranged on the side of installation adjustment plate 1, and dovetail slide 4 is provided in dovetail chute 3;

[0055] The detection head 5 is arranged at the front end of the dovetail slider 4;

[0056] A clamp base 6 is fixed at the bottom of the installation adjustment plate 1, and a clamp is installed on the clamp base 6.

[0057] Among them, the inspection tooling fixture further includes an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com