Diamond special-shaped grinding wheel and vertical machining cooling system

A processing cooling system, diamond technology, applied in metal processing equipment, bonded grinding wheels, manufacturing tools, etc., can solve the problems of high-speed and high-efficiency processing of grinding wheels, low production efficiency, intermittent action, etc., to improve the cooling effect , reduce costs, reduce the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

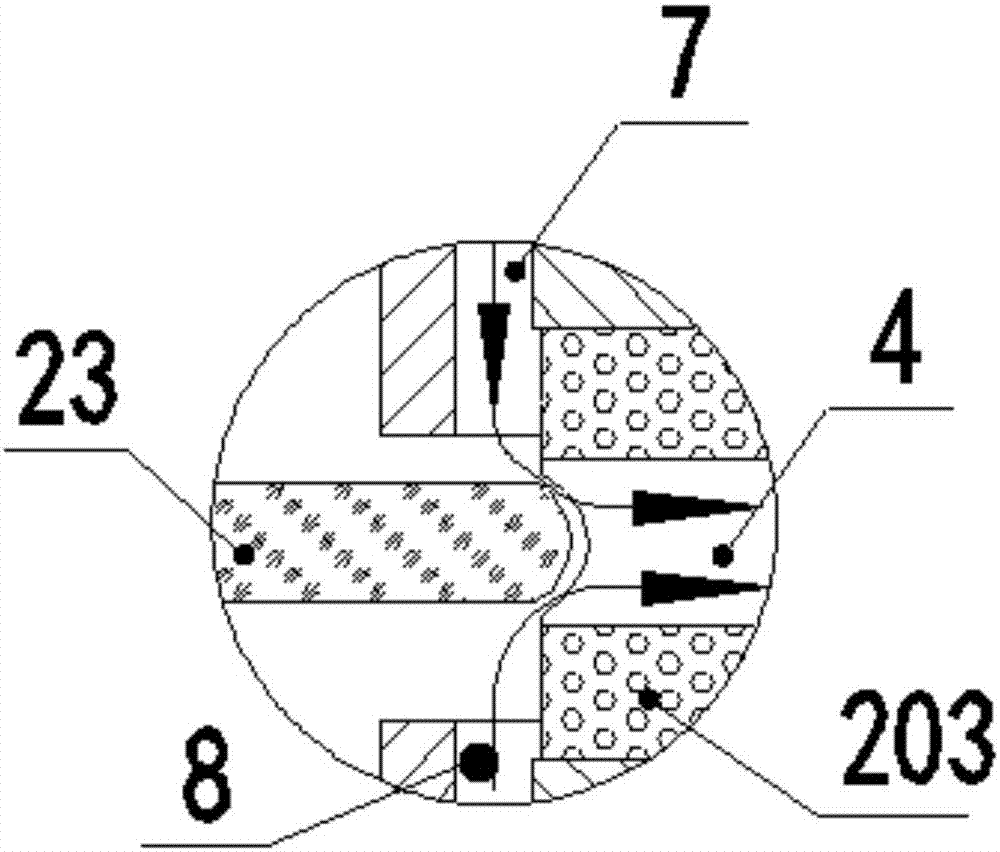

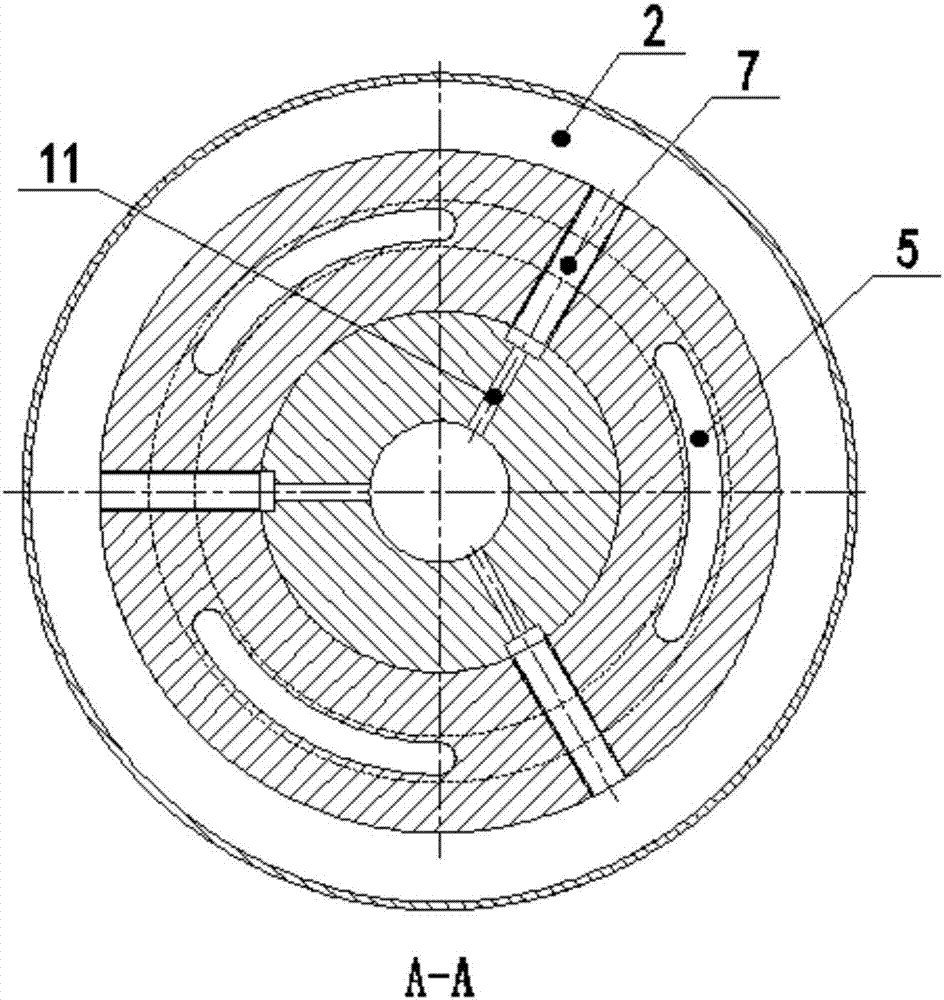

[0060] like Figures 21 to 23 As shown, a diamond special-shaped grinding wheel includes an upper base, a lower base and a grinding ring, the upper base is placed on the upper end of the lower base, and the upper base and the lower base are fixedly connected to form a grinding wheel body; the grinding ring It is annularly consolidated on the outer ring of the grinding wheel body; the grinding wheel body is provided with one or two annular grooves communicating with its upper end surface; the grinding ring is provided with suction cooling water, powder chips and air A plurality of mixed flow channels, one end of each of the mixed flow channels extends to the annular grinding port of the grinding ring, and the other end communicates with a said annular groove, and the multiple mixed flow channels are arranged at equal angles, the said annular The groove communicates with an external negative pressure air source device.

[0061] The grinding ring 203 is in the shape of a ring, a...

Embodiment 3

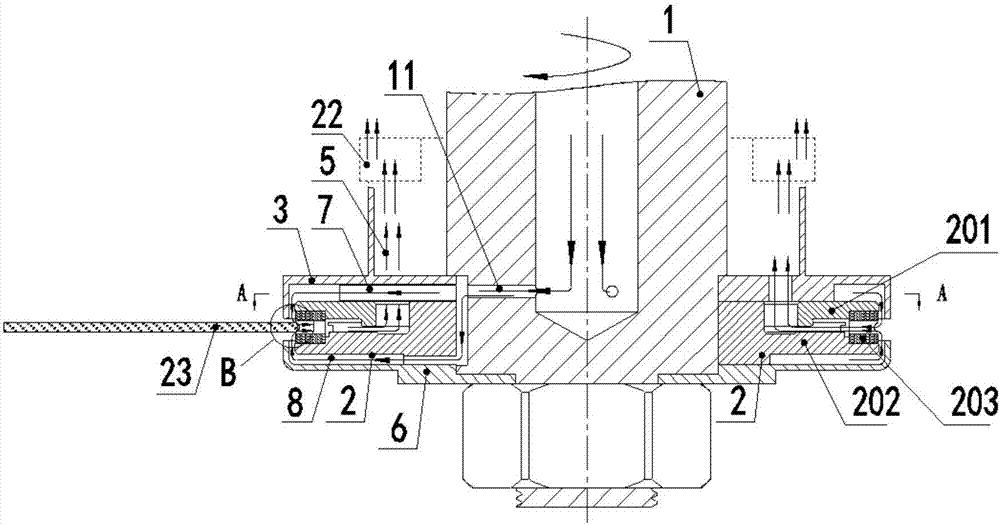

[0074] like Figure 5 to Figure 8 As shown, a vertical processing cooling system includes a rotating spindle 1 and a diamond shaped grinding wheel 2, and the diamond shaped grinding wheel 2 is set on the lower part of the rotating spindle 1; the upper end of the diamond shaped grinding wheel 2 is provided with a ring-shaped The first accessory 3 of the special-shaped diamond grinding wheel 2, the annular groove 204 in the first accessory 3 communicates with the negative pressure channel 5 in the first accessory 3; the cooling water is input above or / and below the grinding port of the special-shaped diamond grinding wheel 2 , The grinding port of the diamond special-shaped grinding wheel 2 is the grinding port of the grinding ring 203, a negative pressure is formed in the negative pressure channel 5, and cooling water, powder chips and air are sucked through the mixed flow channel 4.

[0075] In the above embodiment, the grinding mouth of the diamond special-shaped grinding whe...

Embodiment 4

[0082] like Figure 9 to Figure 11 As shown, a vertical processing cooling system includes a rotating spindle 1 and a diamond shaped grinding wheel 2, and the diamond shaped grinding wheel 2 is set on the lower part of the rotating spindle 1; the upper end of the diamond shaped grinding wheel 2 is provided with a ring-shaped The first accessory 3 of the special-shaped diamond grinding wheel 2, the annular groove 204 in the first accessory 3 communicates with the negative pressure channel 5 in the first accessory 3; the cooling water is input above or / and below the grinding port of the special-shaped diamond grinding wheel 2 , The grinding port of the diamond special-shaped grinding wheel 2 is the grinding port of the grinding ring 203, a negative pressure is formed in the negative pressure channel 5, and cooling water, powder chips and air are sucked through the mixed flow channel 4.

[0083] In the above embodiment, the first attachment 3 wraps the upper part of the diamond s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com