Green platycodon grandiflorus and ginseng fermented yogurt and production method thereof

A technology of ginseng and platycodon grandiflorum, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of backward production technology and insufficient nutrients, and achieve the effects of enhancing heart function, high extraction rate, and enhancing immune function of the body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

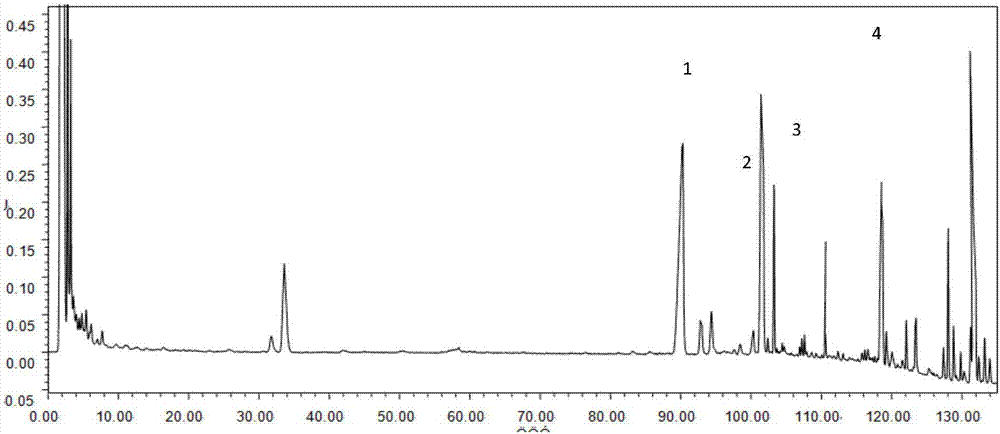

Image

Examples

Embodiment 1

[0034] is obtained by the following steps:

[0035] (1), platycodon ginseng fermented yoghurt formula

[0036] Prepare 1000kg of yogurt, the raw materials account for 4% platycodon, 8% ginseng, 5% working starter, and the rest of fresh milk. The working starter is Streptococcus thermophilus and Lactobacillus bulgaricus, and the ratio of the two is 1 :2;

[0037] (two), raw material pretreatment

[0038] Take platycodon, pulverize into platycodon powder with a particle size of 60 mesh; take ginseng, pulverize into ginseng powder with a particle size of 80 mesh;

[0039] (3) Supercritical fluid extraction of active ingredients of bellflower and ginseng

[0040] Take platycodon root powder, add 2 times entrainer, the entrainer is 70% ethanol solution, put in supercritical extraction equipment, soak at room temperature for 10h, extraction time is 3h, the number of times is 2 times, the temperature is 30 ℃, the pressure is 20MPa, CO 2 Keep the flow rate constant at 12L / h, coll...

Embodiment 2

[0050] is obtained by the following steps:

[0051] (1), platycodon ginseng fermented yoghurt formula

[0052] Prepare 1000kg of yoghurt, the raw materials account for 8% platycodon, 12% ginseng, 8% working starter, and the rest of fresh milk. The working starter is Streptococcus thermophilus and Lactobacillus bulgaricus, and the ratio of the two is 1 :1;

[0053] (two), raw material pretreatment

[0054] Take platycodon, pulverize into platycodon powder with a particle size of 80 mesh; take ginseng, pulverize into ginseng powder with a particle size of 100 mesh;

[0055] (3) Supercritical fluid extraction of active ingredients of bellflower and ginseng

[0056] Get platycodon root powder, add 3.5 times of entrainer, said entrainer is 70% ethanol solution, put in supercritical extraction equipment, soak at room temperature for 11h, extraction time is 4h, frequency is 3 times, temperature is 40 ℃, pressure is 30MPa, CO 2 Keep the flow rate constant at 12L / h, collect the pr...

Embodiment 3

[0066] is obtained by the following steps:

[0067] (1), platycodon ginseng fermented yoghurt formula

[0068] Prepare 1000kg of yoghurt, the raw materials account for 12% by weight of bellflower, 16% of ginseng, 10% of working starter, and the rest of fresh milk. The working starter is Streptococcus thermophilus and Lactobacillus bulgaricus, and the ratio of the two is 2 :1;

[0069] (two), raw material pretreatment

[0070] Take Platycodon grandiflora, pulverize it into platycodon root powder with a particle size of 80 mesh; take ginseng, and crush it into ginseng powder with a particle size of 80 mesh;

[0071] (3) Supercritical fluid extraction of active ingredients of bellflower and ginseng

[0072] Get platycodon root powder, add 5 times of entraining agent, described entraining agent is 70% ethanol solution, place in supercritical extraction equipment, soak 12h at room temperature, extraction time is 5h, the number of times is 4 times, temperature is 50 ℃, pressure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com