Long-term preservation method for frangible rock core

A preservation method and core technology, applied in the field of core polishing and casting, can solve the problems of cutting, observation, testing and analysis difficulties, disintegration of the whole core, unclear structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

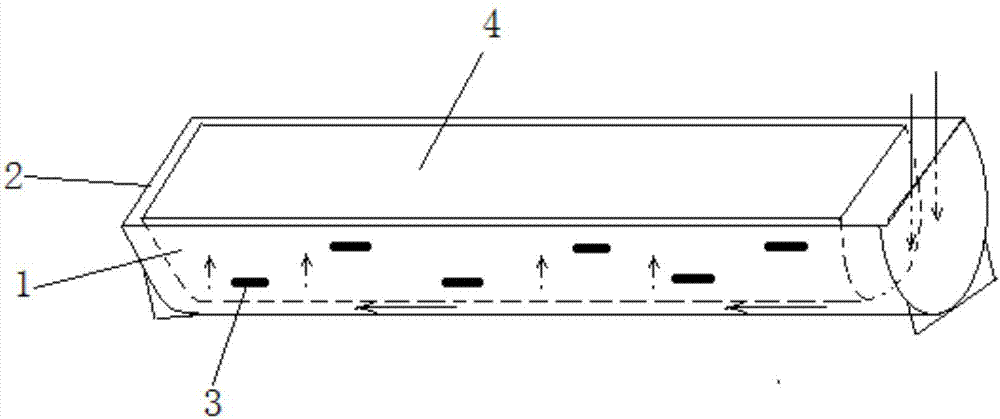

Image

Examples

Embodiment 1

[0037] The present embodiment provides a method for long-term preservation of friable rock cores. The friable rock cores are relatively hard conglomerate, and the method includes the following steps:

[0038] (1) Cutting of the rock core: get the cylindrical type friable rock core, after longitudinally cutting from 1 / 3 of the cross-sectional diameter of the cylindrical type friable rock core, select the rock core body of 1 / 3 diameter to be polished;

[0039] The cylindrical friable core refers to the spliced and sorted rock core, and the splicing and sorting operation of the rock core is specifically: (a) according to the relative position before crushing, the broken rock core blocks are sorted in the core groove, so that each core block The fractures between can be spliced neatly; (b) apply a circle of adhesive on the inner side of the cross-sectional circumference of each rock core block, and then splice and bond the rock core blocks in sequence according to the sequence ...

Embodiment 2

[0045] The present embodiment provides a long-term preservation method of a friable rock core, the friable rock core is medium hardness siltstone, and the method comprises the following steps:

[0046] (1) Cutting of the rock core: get the cylindrical friable rock core, after cutting longitudinally from 1 / 2 of the cross-sectional diameter of the cylindrical friable rock core, select one of the 1 / 2 diameter rock core bodies as the rock core to be polished body;

[0047] The cylindrical friable core refers to the spliced and sorted rock core, and the splicing and sorting operation of the rock core is specifically: (a) according to the relative position before crushing, the broken rock core blocks are sorted in the core groove, so that each core block The fractures between can be spliced neatly; (b) apply a circle of adhesive on the inner side of the cross-sectional circumference of each rock core block, and then splice and bond the rock core blocks in sequence according to t...

Embodiment 3

[0053] The present embodiment provides a method for long-term preservation of friable rock cores, wherein the friable rock cores are mudstone with less hardness, and the method comprises the following steps:

[0054] (1) Cutting of rock core: get cylinder type fragile rock core, after longitudinally cutting from 1 / 3 place of the cross-sectional diameter of described cylindrical type fragile rock core, select the rock core body of 1 / 3 diameter as rock core body to be polished;

[0055] The cylindrical friable core refers to the spliced and sorted rock core, and the splicing and sorting operation of the rock core is specifically: (a) according to the relative position before crushing, the broken rock core blocks are sorted in the core groove, so that each core block The fractures between can be spliced neatly; (b) apply a circle of adhesive on the inner side of the cross-sectional circumference of each rock core block, and then splice and bond the rock core blocks in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com