Leakage checking valve for natural gas pipe network system

A natural gas pipeline network and valve technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of difficulty in removing the medium in the pipeline, leakage of the natural gas pipeline network system, and difficulty in leaking pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

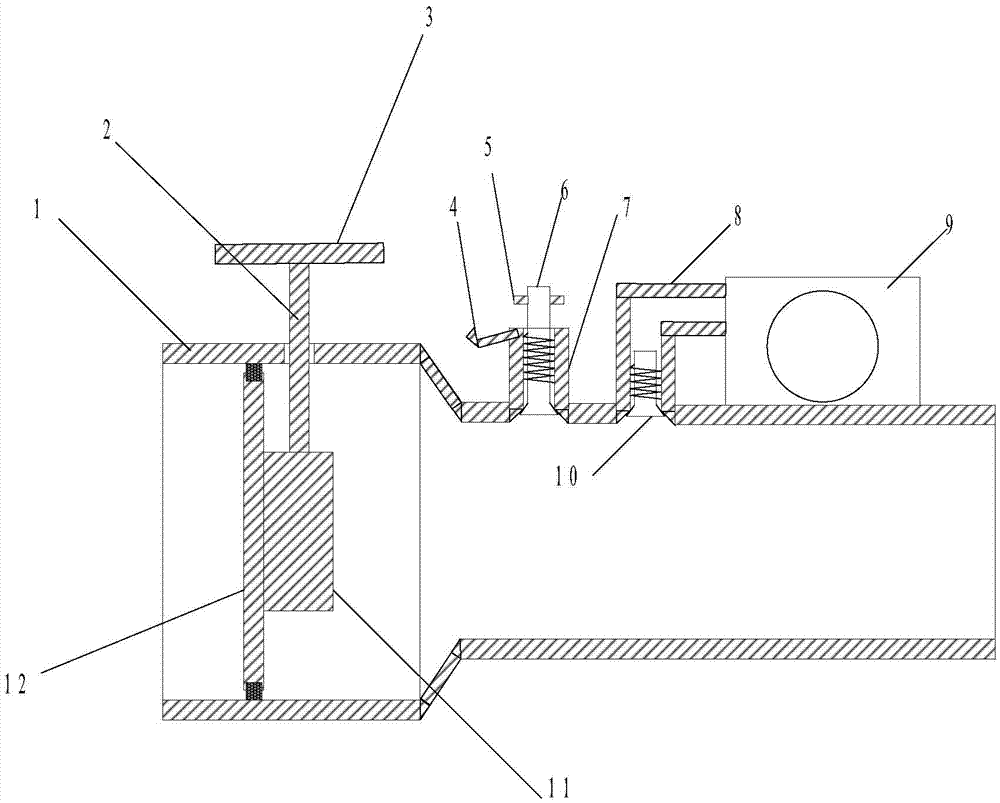

[0015] Such as figure 1 As shown, a leak detection valve for natural gas pipeline network system, including:

[0016] The valve body 1; the two ends of the valve are provided with flanges.

[0017] The circular cut-off plate 12 arranged in the body 1 has a seal ring inlaid on the edge of the cut-off plate 12; the seal ring inlaid on the edge of the cut-off plate 12 is a hard rubber seal ring.

[0018] The transmission mechanism 11 is set at the center of the cut-off plate 12. The transmission mechanism 11 is connected to the manual disc 3 through the transmission rod 2. Rotating the manual disc 3 can make the cut-off plate 12 rotate around the vertical line, so as to cut off or cut off the medium flowing in the pipeline. the purpose of opening;

[0019] The air pressure measuring device arranged at the downstream of the cut-off plate 12, the air pressure measuring device includes a casing 7 facing away from the center line of the body 1 and radially outward, and a first one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com