Curtain wall keel unit, curtain wall unit and curtail wall structure

A single-unit, curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult to guarantee construction quality, high construction period of curtain wall on-site installation, and achieve the effect of high construction efficiency, easy connection accuracy, and improved construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

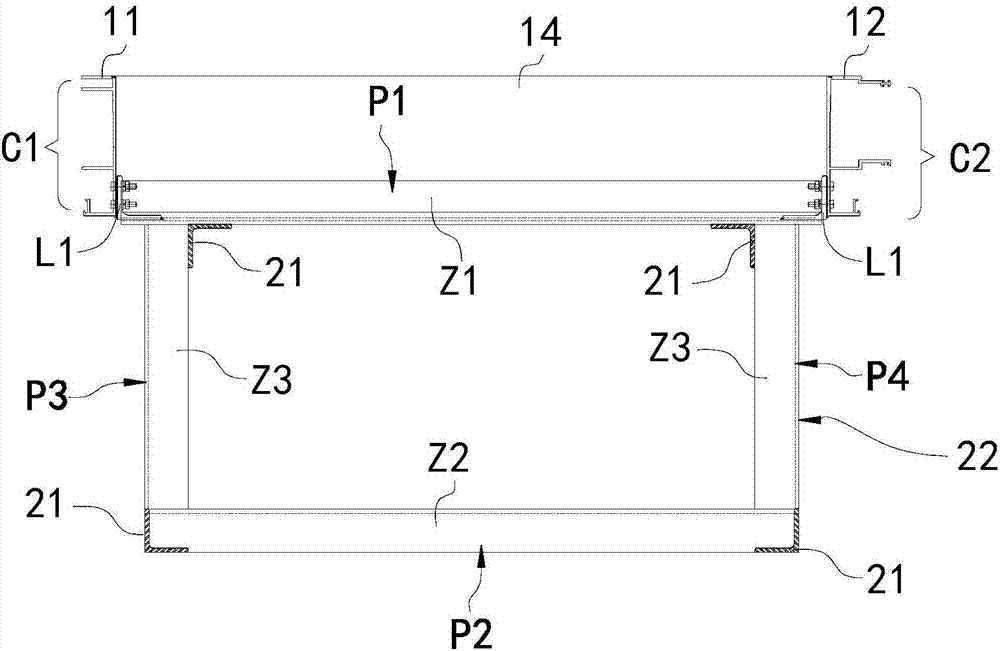

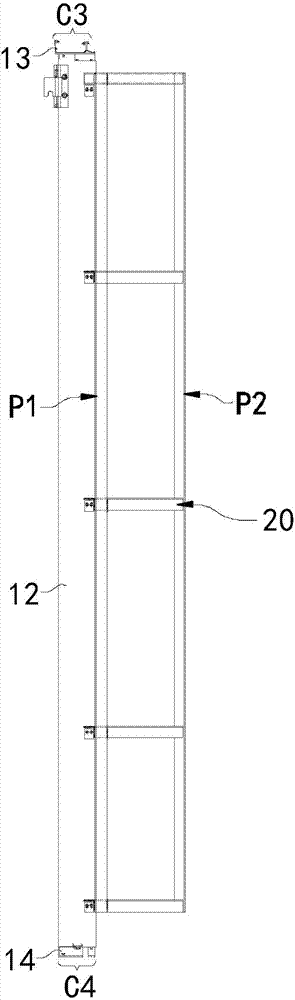

[0047] figure 1 It is a structural schematic diagram of the curtain wall keel unit 100 in the embodiment of the present invention; figure 2 yes figure 1 A-direction view; image 3 yes figure 1 B direction view, the three together show the structure of the curtain wall joist unit 100 in this embodiment. To show the structure clearly, figure 2 image 3 Part of the structure is hidden and not shown. Please refer to figure 1 (for coordination see figure 2 , image 3 ), the curtain wall joist unit 100 in this embodiment includes a first frame 10 and a second frame 20. The first frame 10 and the second frame 20 are detachably connected together through the connecting piece L1.

[0048] The first frame 10 will be specifically described below.

[0049] See figure 1 , the first frame 10 includes a first frame column 11 and a second frame column 12 facing each other along a first preset direction Y1 , and a third frame column 13 and a fourth frame column 14 facing each ot...

Embodiment 2

[0061] Figure 6 It is a structural schematic diagram of the curtain wall unit 010 in the embodiment of the present invention. See Figure 6 , the curtain wall unit 010 in this embodiment includes the curtain wall joist unit 100 in Embodiment 1, and also includes a first panel 31 , a second panel 32 and a third panel 33 . The first panel 31 , the second panel 32 and the third panel 33 are respectively connected to the curtain wall joist unit 100 and cover the surface of the curtain wall joist unit 100 to separate the interior and exterior spaces of the building and ensure the relative independence of the interior space of the building.

[0062] The following describes in detail how the first panel 31 , the second panel 32 , the third panel 33 are connected to the curtain wall joist unit 100 in this embodiment.

[0063] Please continue to see Figure 6 , the first panel 31 in this embodiment is connected to the second frame 20, and the first panel 31 is located outside the s...

Embodiment 3

[0068] Figure 7 It is a schematic diagram of the curtain wall structure 001 in the embodiment of the present invention; Figure 8 yes Figure 7 Sectional view along line VIII-VIII; Figure 9 for Figure 8 Detailed enlarged view at D in . in Figure 7 , Figure 8 It is a simple schematic diagram, and some structures are briefly shown.

[0069] See Figure 7 , Figure 8 , Figure 9 , the curtain wall structure 001 in this embodiment includes a plurality of curtain wall unit elements 010 in the second embodiment, a plurality of independent keels 020 composed of the first frame 10 in the second embodiment, and a fourth panel 34 . The first frames 10 in the independent keel 020 and the first frames 10 in the curtain wall unit 010 are distributed in a matrix, and the adjacent sides of the adjacent first frames 10 are connected to each other to form an integrated rectangular lattice keel system. Each independent keel 020 is mated with a fourth panel 34 , and the fourth pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com