Oxidized graphene dry-jetting and wet-spinning method

A graphene, dry spray wet technology, applied in dry spinning, wet spinning, textiles and papermaking, etc., can solve problems such as unfavorable industrial production, low graphene fiber strength, complicated spinning raw material preparation process, etc. It is convenient for industrial production, eliminating the screening process and improving the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

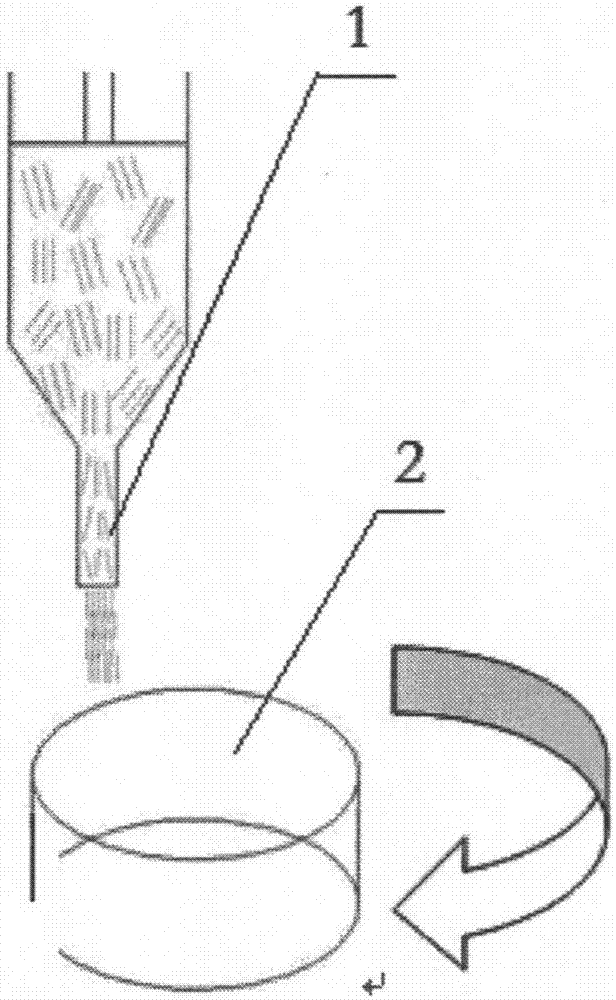

[0038] A kind of graphene oxide dry jet wet spinning spinning method, concrete steps are:

[0039] 1. Prepare graphene oxide by the improved Hummers method:

[0040] Step 1: Mix 360 milliliters of concentrated sulfuric acid (80% to 99%) and 40 milliliters of phosphoric acid (40% to 99%) in a volume ratio of 9:1 and place in an ice bath, slowly add 3g of 80 mesh graphite And 18g potassium permanganate, and stir with glass rod, obtain mixed solution;

[0041] Step 2: Magnetically stir the mixture obtained in Step 1 at 50°C for 12 hours. After cooling to room temperature, put it in an ice bath and add 20ml of 30% hydrogen peroxide solution until the solution turns bright yellow;

[0042] Step 3: Dilute the solution obtained in step 2 to 1 liter to 2 liters with deionized water, vacuum filter to remove the strong acid in the mixed solution, and wash the solid obtained by suction filtration with 200-500 ml of 30% hydrochloric acid, Then perform vacuum filtration to obtain graphen...

Embodiment 2

[0050] A kind of graphene oxide dry jet wet spinning spinning method, concrete steps are:

[0051] 1. Prepare graphene oxide by the improved Hummers method:

[0052] Step 1: Mix 360 milliliters of concentrated sulfuric acid (80% to 99%) and 40 milliliters of phosphoric acid (40% to 99%) in a volume ratio of 9:1 and place in an ice bath, slowly add 3g of 325 mesh graphite And 18g potassium permanganate, and stir with glass rod, obtain mixed solution;

[0053] Step 2: Magnetically stir the mixture obtained in Step 1 at 50°C for 12 hours. After cooling to room temperature, put it in an ice bath and add 20ml of 30% hydrogen peroxide solution until the solution turns bright yellow;

[0054] Step 3: Dilute the solution obtained in step 2 to 1 liter to 2 liters with deionized water, vacuum filter to remove the strong acid in the mixed solution, and wash the solid obtained by suction filtration with 200-500 ml of 30% hydrochloric acid, Then perform vacuum filtration to obtain graphe...

PUM

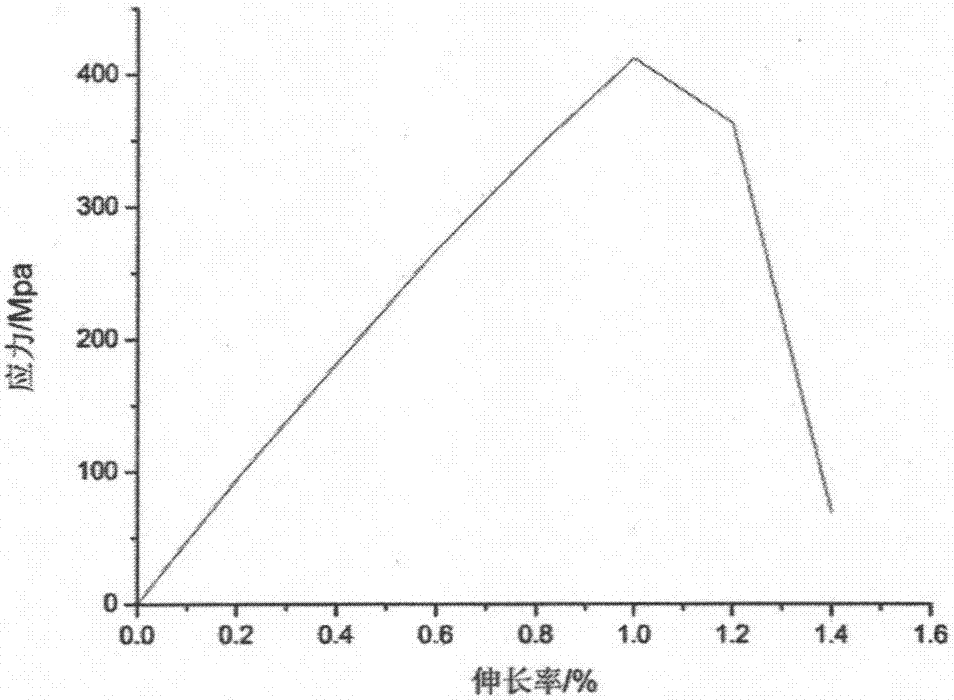

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com