Biological-based polyamide and preparation method thereof

A bio-based polyamide and a bio-based technology are applied in the fields of bio-based polyhexamethylene azelaate and its preparation, bio-based polyamide and its preparation, and can solve the problems of complicated operation steps and technological processes, and monomer escape. , monomer ratio imbalance and other problems, to achieve the effect of alleviating the increasing depletion of fossil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

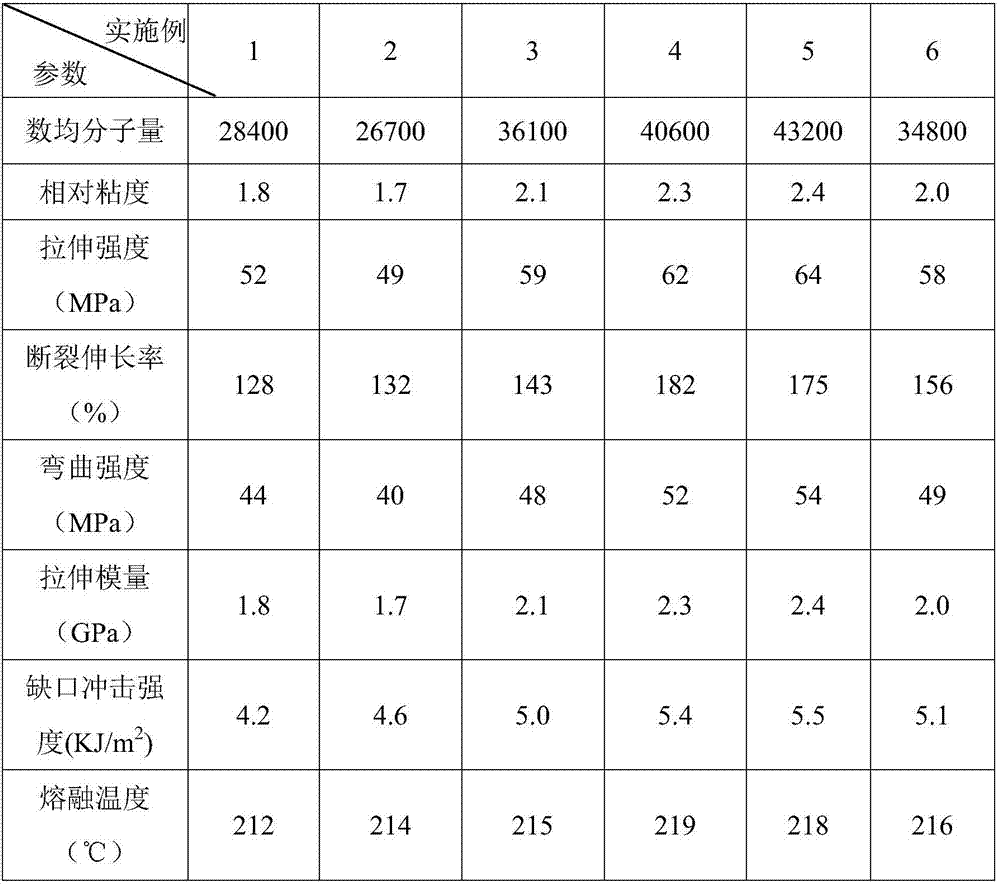

Embodiment 1

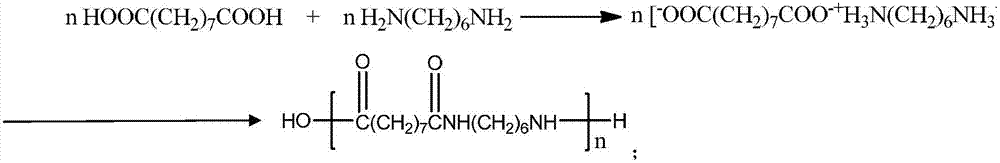

[0036] A preparation method of bio-based polyamide, comprising the following steps:

[0037] Preparation of mixed solution of 1,6-hexamethylenediamine and 1,9-azelaic acid: add 1,6-hexamethylenediamine (slightly warmed before use to make it melt from crystal to liquid) into 1,9-azelaic acid, follow The mass ratio of the reaction monomer (that is, the mass sum of 1,9-azelaic acid and 1,6-hexanediamine) to deionized water is 1:0.3. Add deionized water and stir at 400r / min for 2 minutes A mixed solution is then prepared.

[0038] Preparation of polyhexamethylene azelaic acid amide: Add the mixed solution of 1,6-hexanediamine and 1,9-azelaic acid into the polymerization kettle through the feed port of the polymerization kettle, seal the polymerization kettle, 1,9-nonanedioic acid The monomer molar ratio of diacid and 1,6-hexamethylenediamine is 1:1.008; then the atmosphere in the polymerization kettle is replaced with nitrogen atmosphere, and the method of replacing the atmospher...

Embodiment 2

[0041] A preparation method of bio-based polyamide, comprising the following steps:

[0042] Preparation of mixed solution of 1,6-hexamethylenediamine and 1,9-azelaic acid: add 1,6-hexamethylenediamine (slightly warmed before use to make it melt from crystal to liquid) into 1,9-azelaic acid, follow The mass ratio of reaction monomer (that is, the mass sum of 1,9-azelaic acid and 1,6-hexanediamine) to deionized water is 1:0.9, add deionized water, and stir at a speed of 100r / min for 10 minutes A mixed solution is then prepared.

[0043] Preparation of polyhexamethylene azelaic acid amide: Add the mixed solution of 1,6-hexanediamine and 1,9-azelaic acid into the polymerization kettle through the feed port of the polymerization kettle, seal the polymerization kettle, 1,9-nonanedioic acid The monomer molar ratio of diacid and 1,6-hexanediamine is 1:1.01; then the atmosphere in the polymerization kettle is replaced with nitrogen atmosphere, and the method of replacing the atmosphe...

Embodiment 3

[0046] A preparation method of bio-based polyamide, comprising the following steps:

[0047] Preparation of mixed solution of 1,6-hexamethylenediamine and 1,9-azelaic acid: add 1,6-hexamethylenediamine (slightly warmed before use to make it melt from crystal to liquid) into 1,9-azelaic acid, follow The mass ratio of the reaction monomer (that is, the mass sum of 1,9-azelaic acid and 1,6-hexanediamine) to deionized water is 1:0.7. Add deionized water and stir at a speed of 150r / min for 8 minutes A mixed solution is then prepared.

[0048] Preparation of polyhexamethylene azelaic acid amide: Add the mixed solution of 1,6-hexanediamine and 1,9-azelaic acid into the polymerization kettle through the feed port of the polymerization kettle, seal the polymerization kettle, 1,9-nonanedioic acid The monomer molar ratio of diacid and 1,6-hexanediamine is 1:1.005; then the atmosphere in the polymerization tank is replaced with nitrogen atmosphere, and the method of replacing the atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com