Helical coating type welding wire weaving machine

A wrapping and welding wire technology, which is applied in welding medium, welding equipment, transportation and packaging, etc., can solve the problems of poor control effect, high cost, inconvenient use, etc., and achieve beautiful appearance, material and cost saving, and simple control way effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

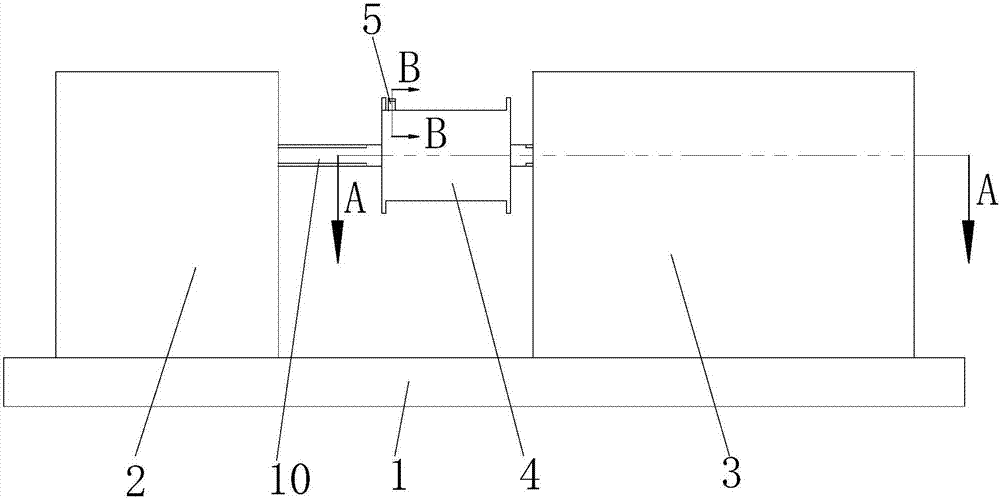

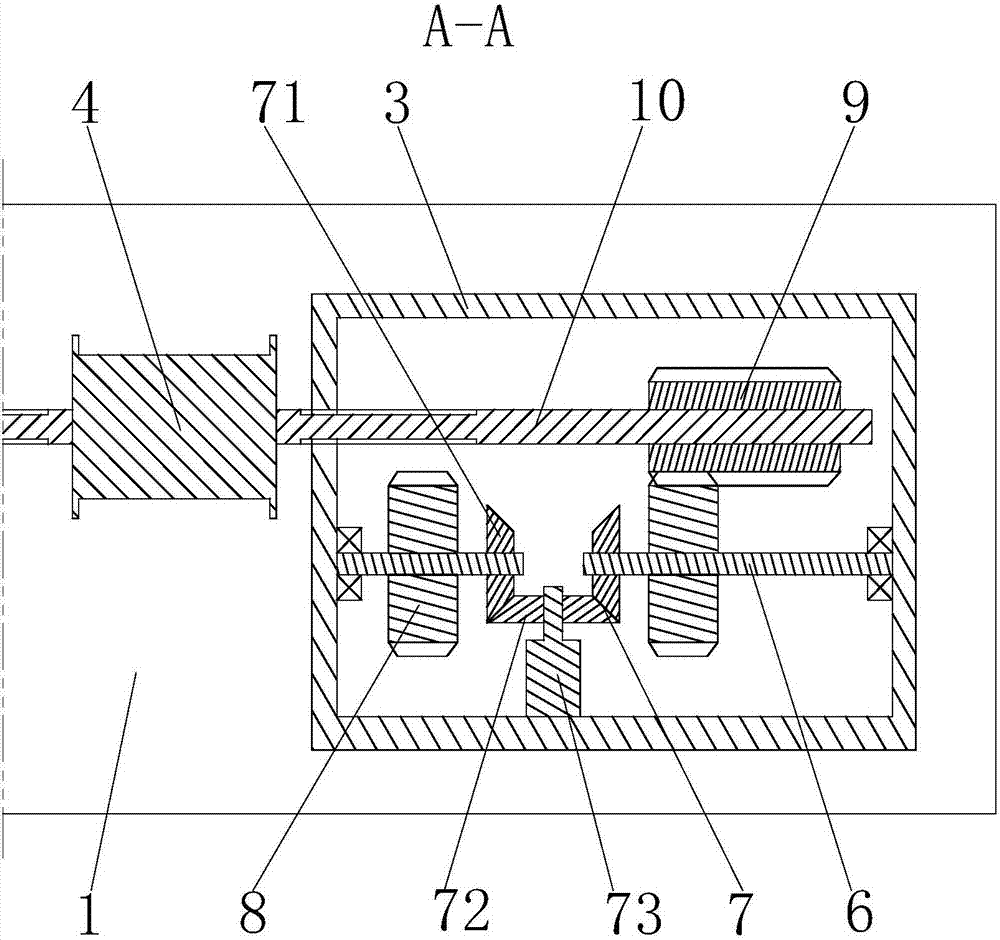

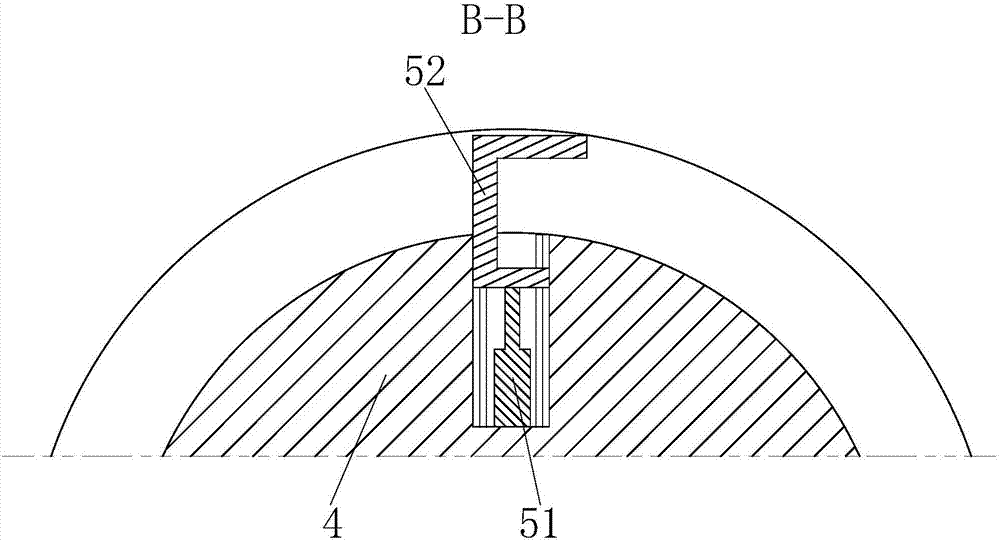

[0019] Such as Figure 1 to Figure 3 As shown, a spiral-wrapped welding wire braiding machine includes a frame 1, a left chassis 2 and a right chassis 3 are fixedly mounted on the chassis 1, and a long braiding wheel 4 is arranged between the left chassis 2 and the right chassis 3. The long weaving wheel 4 is relative to the weaving cylinder. The long weaving wheel 4 is provided with an initial fixing device 5; the left side and the right side of the long weaving wheel 4 are connected with a rotating shaft 10, and the two rotating shafts 5 are in one-to-one correspondence with the left chassis 2 and the right chassis 3 respectively. Threaded connections fit.

[0020] Two coaxial sub-shafts 6 are installed inside the right chassis 3 through bearings; a bevel gear direction changing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com