Intelligent slag scraping equipment for galvanized steel sheet production and galvanized steel sheet production process

A technology of galvanized steel sheet and slag scraping device, which is applied in hot-dip plating process, metal material coating process, cleaning method using tools, etc., can solve problems such as troublesome adjustment, easy accumulation of zinc slag, and poor practicability. Achieve the effects of avoiding extrusion deformation, improving slag scraping efficiency, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

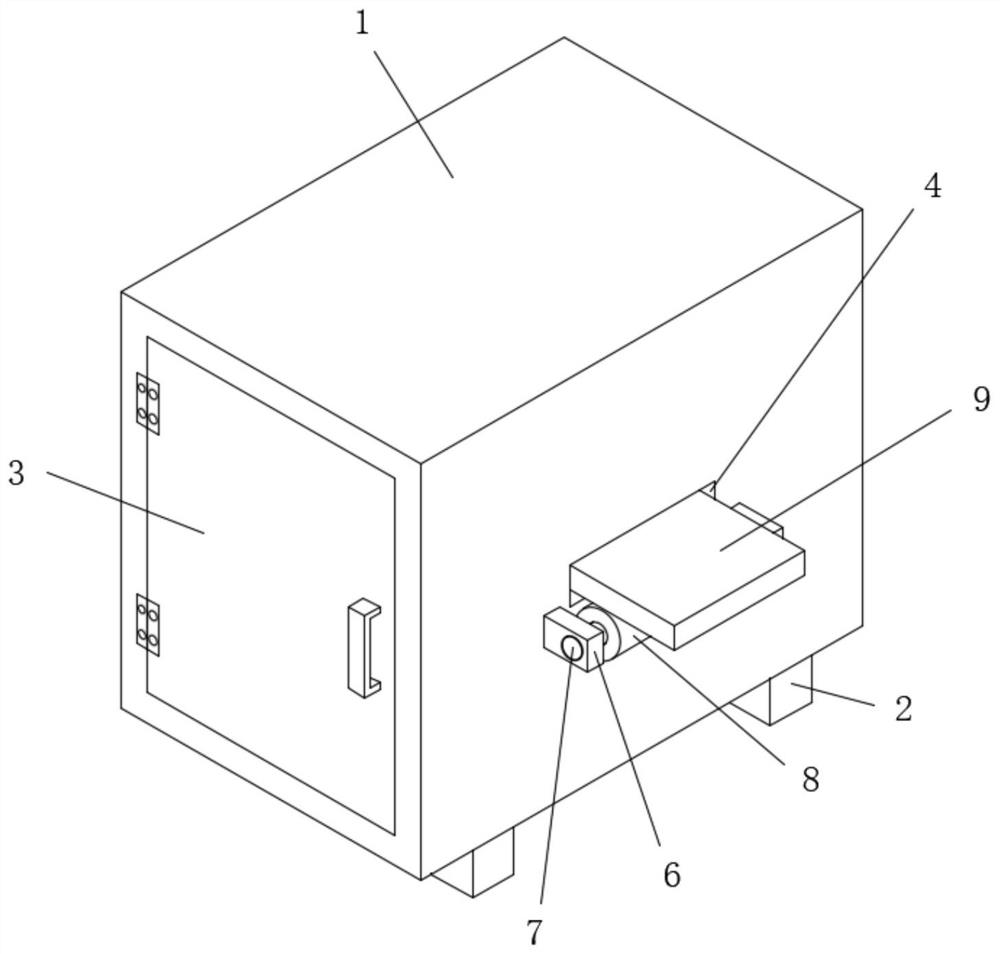

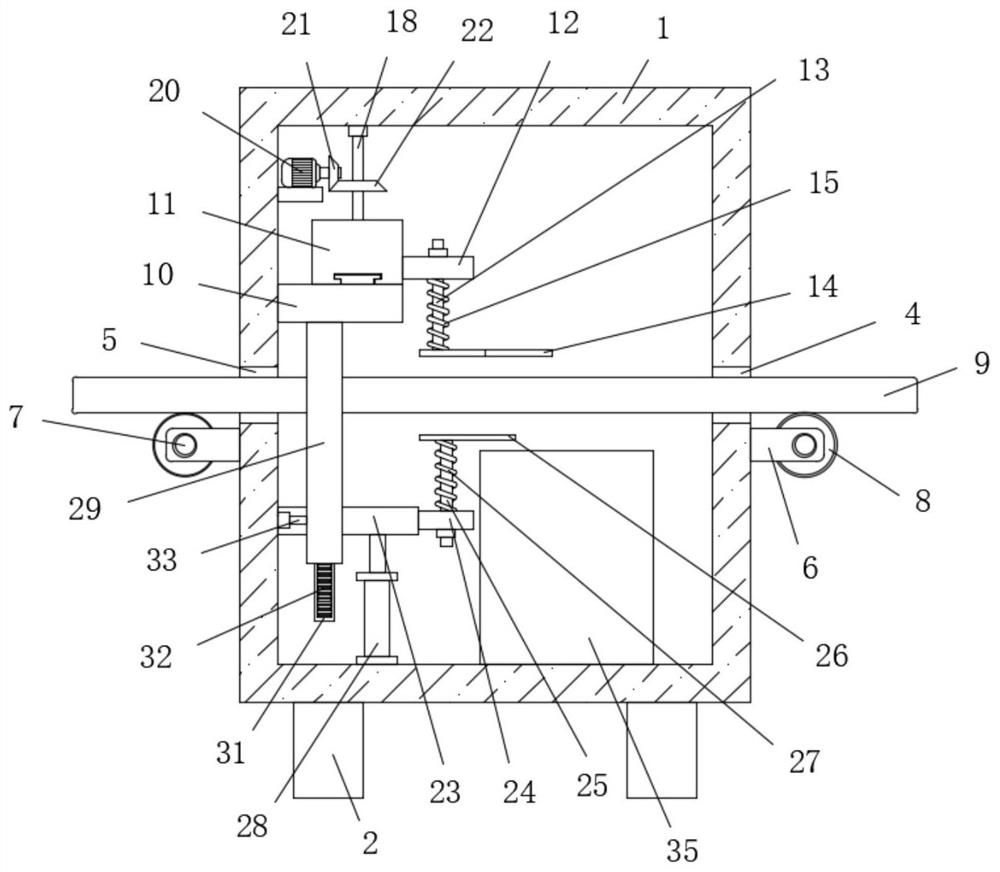

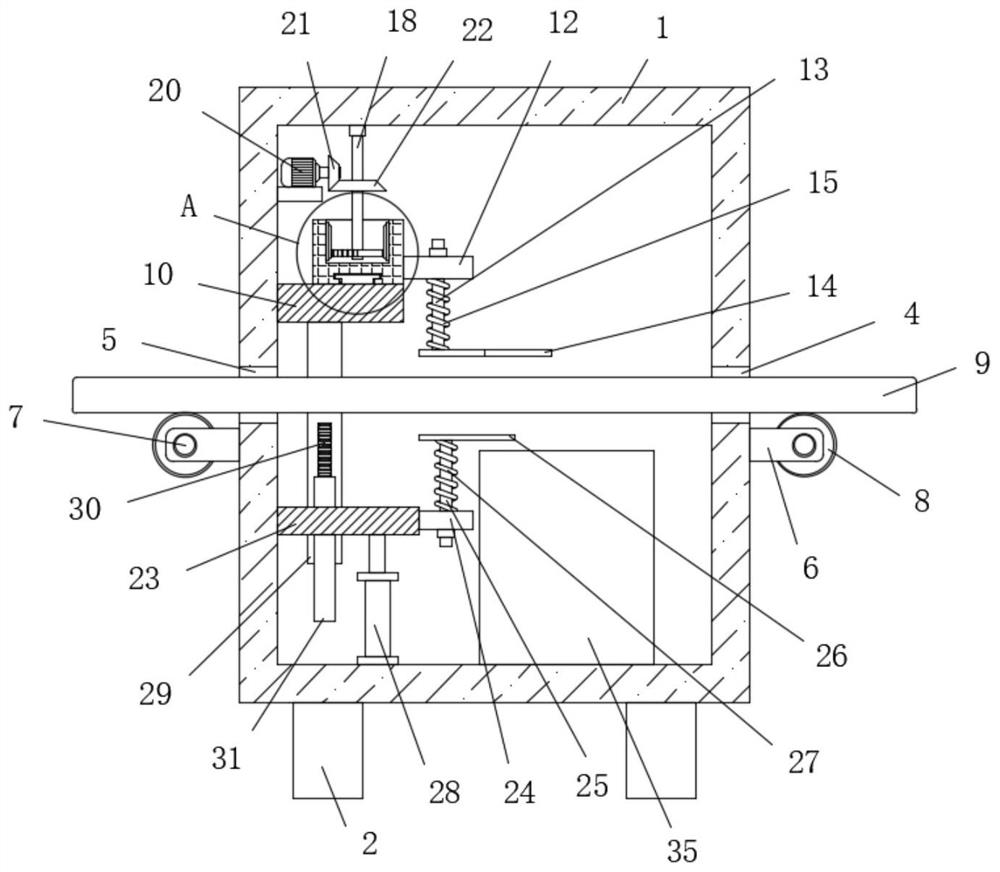

[0037] refer to Figure 1-9 , an intelligent double-sided slag scraping device for galvanized steel production, comprising a box body 1, four corners of the bottom outer wall of the box body 1 are provided with supporting legs 2, one side of the box body 1 is provided with a box door 3, the box body 1 The sides of the body 1 away from each other are symmetrically provided with a material inlet 4 and a material outlet 5, and the outer walls of both sides of the box body 1 are symmetrically provided with two sets of guide components respectively located under the material inlet 4 and the material outlet 5. , the same galvanized steel plate 9 runs through the feed port 4 and the discharge port 5, and the two sets of guide components are respectively matched with the bottom of the galvanized steel plate 9 on both sides outside the box body 1, and the box body 1 is close to the outlet One side of the inner wall of the feed port 5 is vertically slidably connected with an upper slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com