Electric-shock-proof power supply device

A power supply device and anti-electric shock technology, which is applied in the direction of coupling devices, components of connecting devices, circuits, etc., can solve problems such as personnel electric shock and potential safety hazards, and achieve the prevention of movement deviation, increase safety, and facilitate automatic power supply and disconnection. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

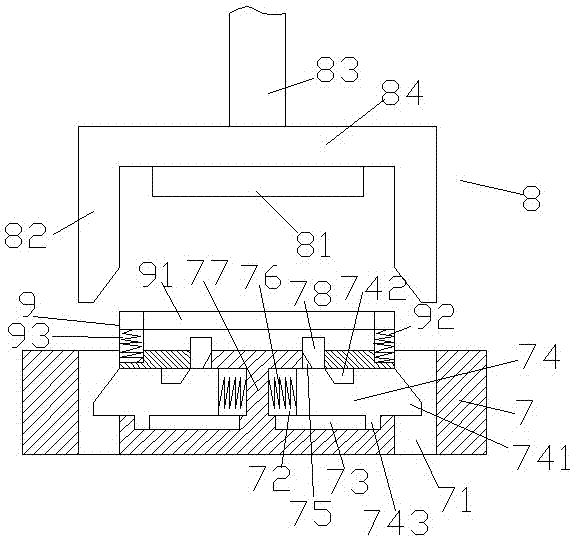

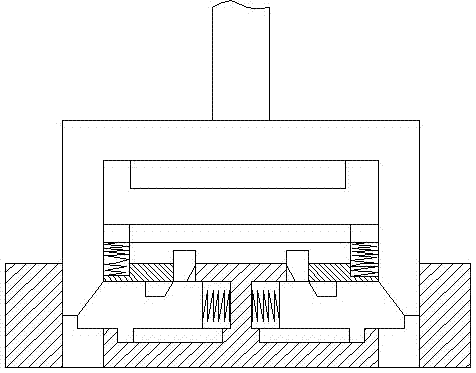

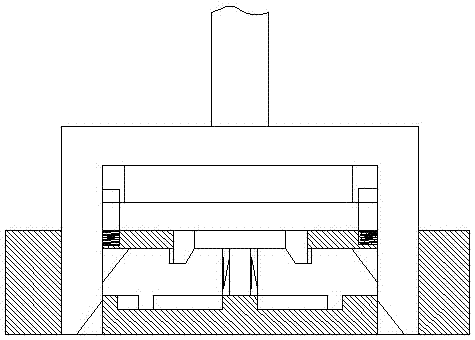

[0018] Such as Figure 1-Figure 4 As shown, an electric shock-proof power supply device of the present invention includes a socket part 8 and a socket part 7 arranged at the lower end of the socket part 8, and the socket part 8 includes a connecting rod 84, a contact piece 81 and wires 83, both sides of the connecting rod 84 are fixedly provided with downwardly extending oblique insertion rods 82, and the upper end of the socket part 7 is provided with a sliding frame 9 that is symmetrical to the left and right and extended upwardly. The upper end of the frame 9 is provided with a limit block 94, and each of the slide frames 9 is provided with a lower pressure groove 93, and each of the lower pressure grooves 93 is provided with a first compression spring 92, and the two lower pressure grooves 93 are provided with a first compression spring 92. A conductive piece 91 is connected to the sliding fit between the pressure grooves, and the upward extension end of the first compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com