Engineering parameter measurement while drilling device of deep water drill string

An engineering parameter and measurement-while-drilling technology, which is applied in measurement, earthwork drilling, wellbore/well components, etc., can solve problems such as insufficient accuracy, high service costs, and inability to drill platforms, etc., and achieves easy installation and replacement, and system The effect of simple structure and convenient on-site implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

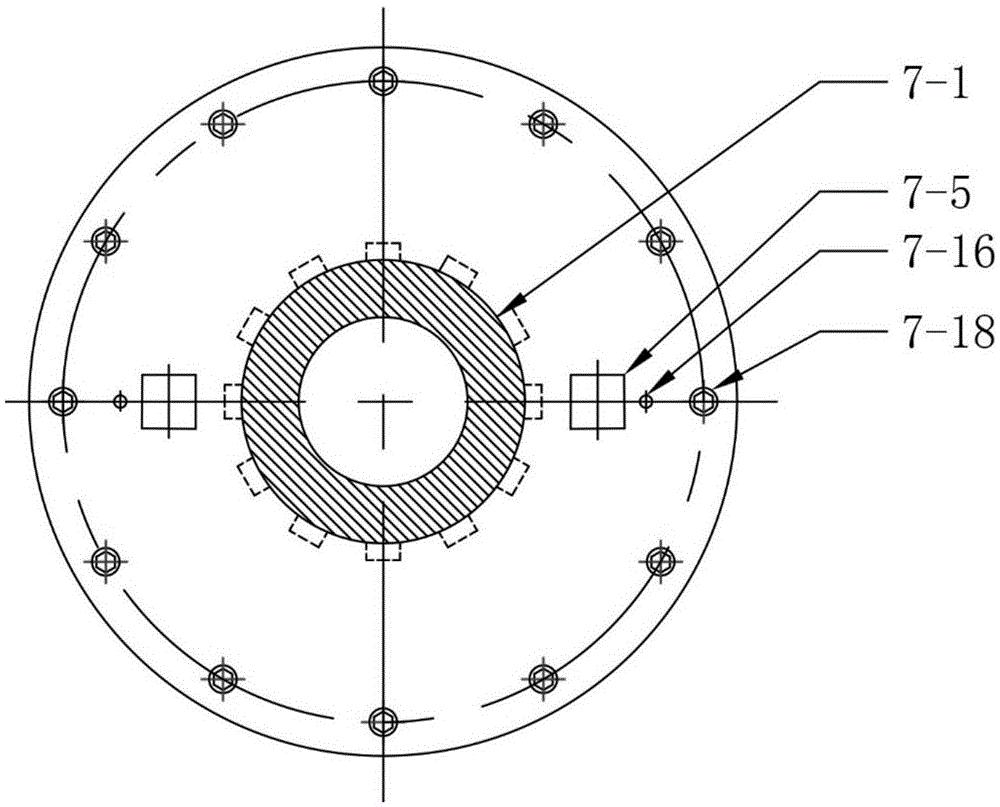

[0032] Such as figure 1 As shown, the present invention specifically provides an engineering parameter measurement-while-drilling device for a deepwater drill string, said device comprising: a top drive 3, a drill string 4, a measurement nipple 7, a data transmission module 9 and a data transmission module 10; The top drive 3 is used to provide the driving force of the drill string 4; the top of the measuring nipple 7 is connected to the top drive 3, and the bottom of the measuring nipple 7 is connected to the drill string 4 for Collect the engineering parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com