A kind of shaping method of alloy

An alloy and deformation technology, applied in the field of alloys, can solve the problems of difficult shaping and processing of alloy products, and achieve the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example is used to illustrate the shaping method of the alloy of the present invention.

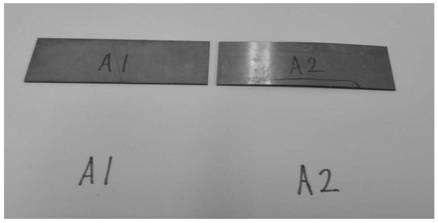

[0047] The 304 stainless steel plate (purchased from Xinshunxiang Stainless Steel Co., Ltd.) was made into two samples A1 and A2 of length 70mm×width 30mm×thickness 1.2mm. The flatness of sample A1 was 0.03mm, and the sample A2 was bent and deformed. Samples A1 and A2 as figure 2 shown.

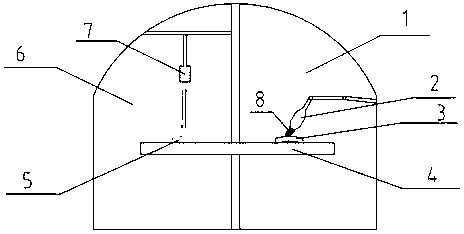

[0048] Place sample A2 in such as figure 1 In the shaping device shown, the deformation of sample A2 is measured in the measurement area, and the maximum deformation of the measurement result is 1.51mm. Rotate sample A2 from the measurement area to the shaping processing area, and use the compressed air mixed shaping fluid with a pressure of 0.4Mpa containing B505 ceramic particles (purchased from Henglida Surface Treatment Materials Co., Ltd., with a particle size of 10-30 μm) to sample A2. Plastic processing, the mixing ratio of B505 ceramic particles and compressed air is 1×10 5 pcs / L...

Embodiment 2

[0050] This example is used to illustrate the shaping method of the alloy product of the present invention.

[0051] will be composed of Zr 52 Cu 30 Al 10 Ni 7 Er 1 The zirconium-based amorphous alloy (purchased from BYD Co., Ltd.) was prepared by casting into an amorphous alloy mobile phone middle frame with a size of 132 mm in length × 65 mm in width × 1.2 mm in thickness, denoted as sample B1, as Figure 4 shown. The glass transition temperature of the zirconium-based amorphous alloy is 430° C., the crystallization temperature is 500° C., the hardness is 500 HV, and the tensile strength is 1800 MPa.

[0052] Place sample B1 into the figure 1 In the shaping device shown, the deformation of sample B1 is measured in the measurement area, and the measurement result shows that the maximum deformation is 0.04mm. Rotate sample B1 from the measurement area to the shaping processing area, and use compressed air mixed shaping fluid with a pressure of 0.65Mpa containing B505 ce...

Embodiment 3

[0054] This example is used to illustrate the shaping method of the alloy product of the present invention.

[0055] will be composed of Zr 52 Cu 30 Al 10 Ni 7 Er 1 The zirconium-based amorphous alloy (purchased from BYD Co., Ltd.) is prepared by casting into an amorphous alloy mobile phone middle frame with a size of 132 mm in length × 65 mm in width × 1.2 mm in thickness, which is designated as sample C1, such as Figure 4 shown. The glass transition temperature of the zirconium-based amorphous alloy is 430° C., the crystallization temperature is 500° C., the hardness is 500 HV, and the tensile strength is 1800 MPa.

[0056] Place sample C1 as figure 1 In the shaping device shown, the deformation of the sample C1 is measured in the measurement area, and the measurement result shows that the maximum deformation is 0.04 mm. Rotate sample C1 from the measurement area to the shaping processing area, and use compressed air mixed shaping fluid with a pressure of 0.1Mpa cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com