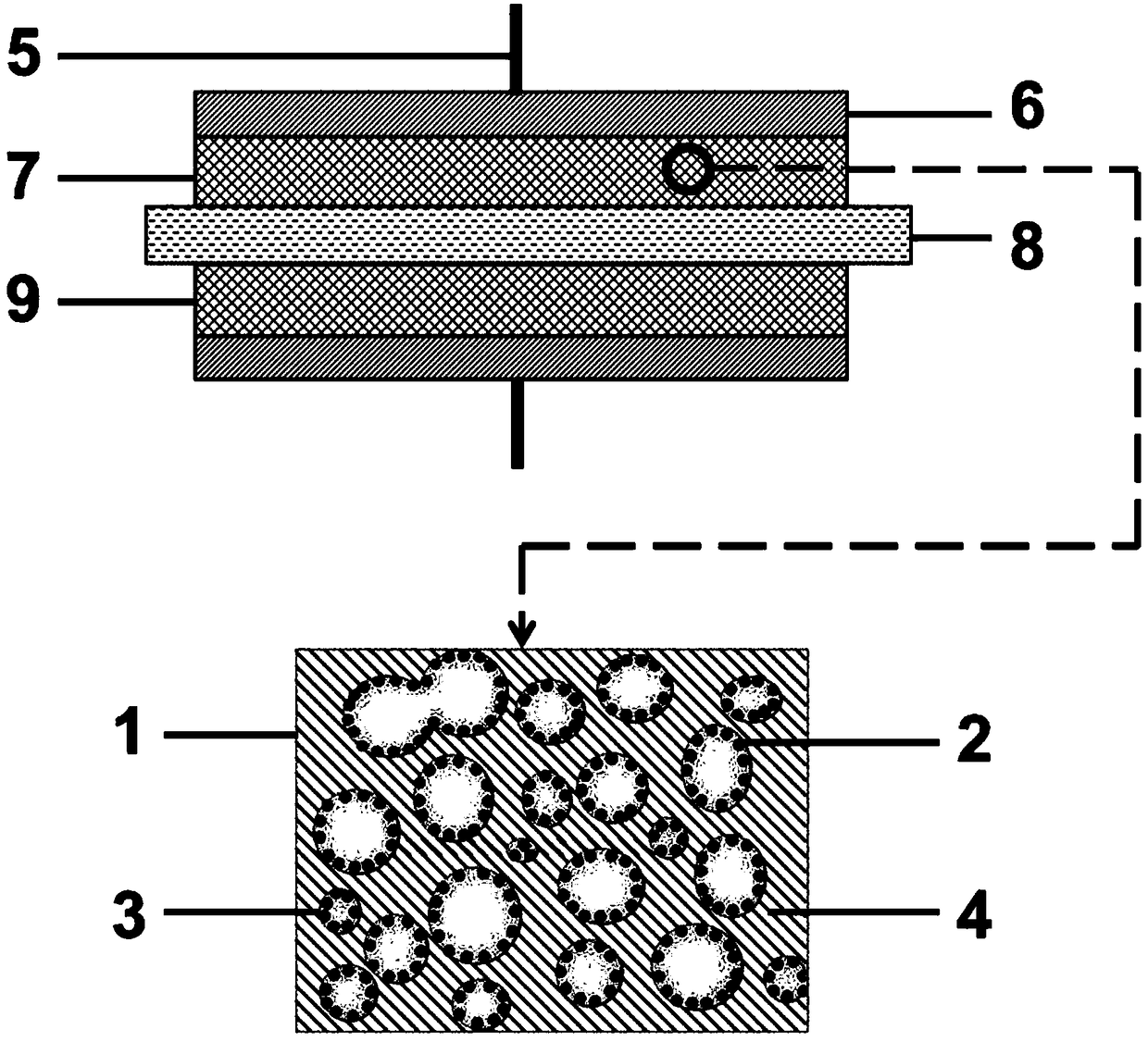

A supercapacitor based on porous strontium lanthanum cobaltate substrate loaded with silver nanoparticles

A supercapacitor, strontium lanthanum cobaltate technology, applied in the field of high-performance supercapacitors, can solve the problems that affect the wide application of supercapacitors, limit the loading capacity of active materials, and the high cost of noble metal substrates, so as to increase the reactive area and active sites , strong cycle stability and stable load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

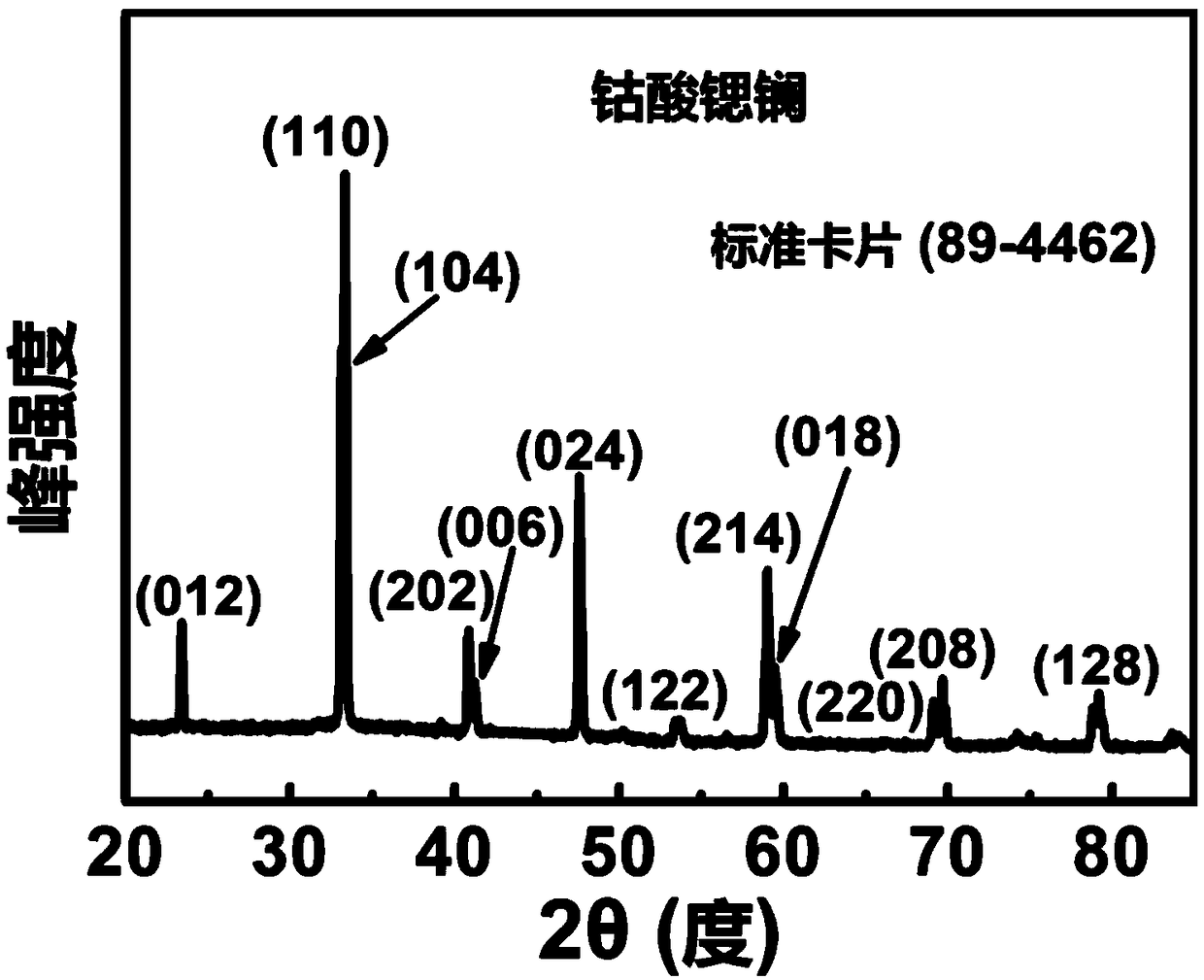

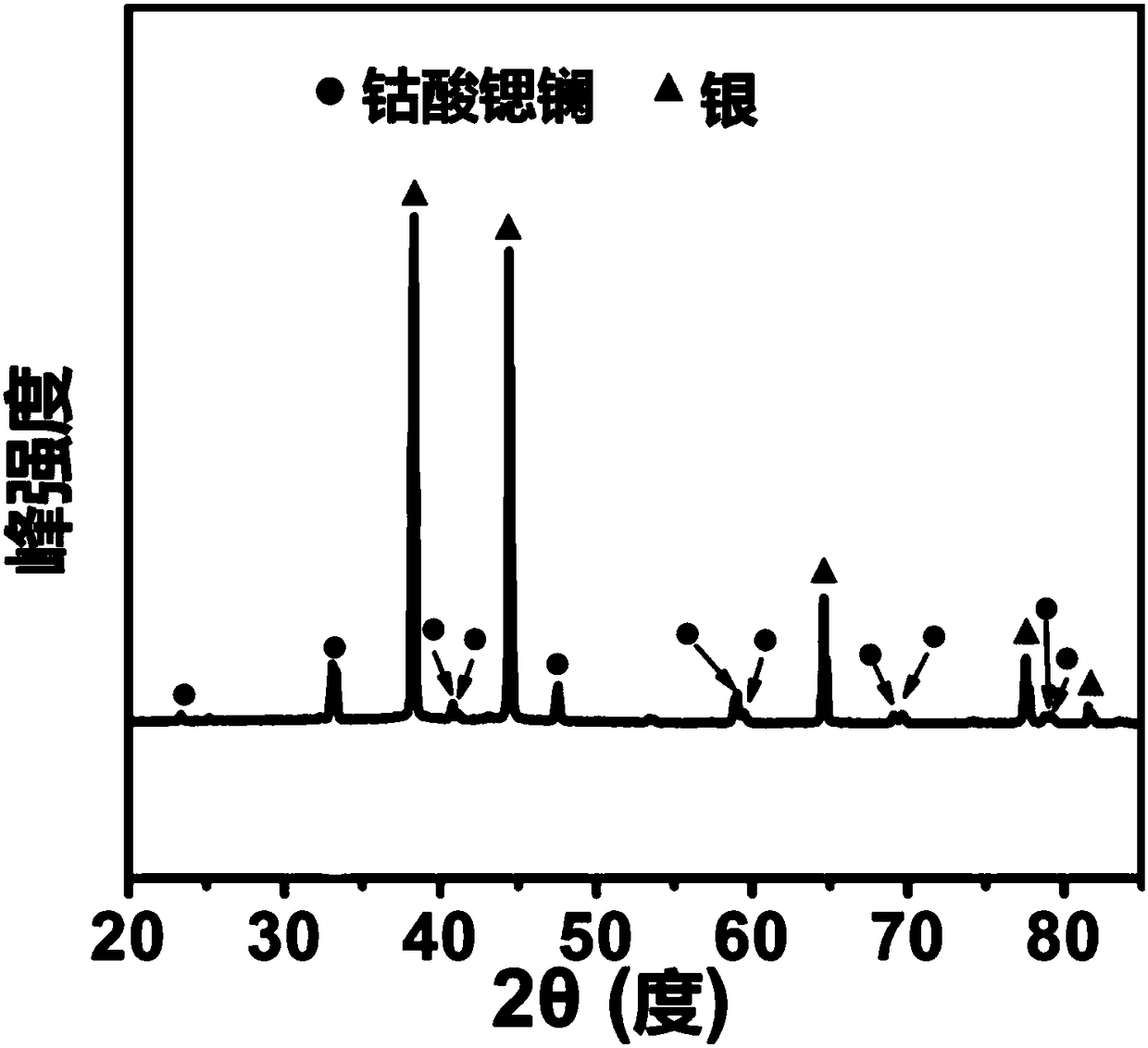

[0047] (1) Electrode material Ag / La 0.7 Sr 0.3 CoO 3‐δ (La 0.7 Sr 0.3 CoO 3‐δ , x=0.3, referred to as: LSC0.3) preparation: first lanthanum oxide (La 2 o 3 , Sinopharm Chemical Reagent Co., Ltd., high-purity) calcined in the air at 1000°C for 2h to remove the moisture; then the calcined La 2 o 3 with strontium carbonate (SrCO 3 , Guangzhou Chemical Reagent Factory, analytically pure), tricobalt tetroxide (Co 3 o 4 , Aladdin, analytically pure), according to La 0.7 Sr 0.3 CoO 3‐δ The stoichiometric ratio in the mixture was weighed in turn, put into a 100ml ball mill jar, and an appropriate amount of absolute ethanol (CH 3 CH 2 OH, Tianjin Fuyu Fine Chemical Co., Ltd., analytically pure), ball milled for 11 h, and then dried under an infrared lamp to obtain a gray powder. The gray powder was placed in a high temperature furnace, calcined in air at 1000°C for 11 h, and cooled naturally to room temperature to obtain a black powder. This powder is carried out X-ray ...

Embodiment 2

[0066] (1) Cathode material Ag / LaCoO 3 (La 1‐x Sr x CoO 3‐δ , x=0) preparation: first La 2 o 3 Calcined at 1000°C for 4h to remove the moisture; then the calcined La 2 o 3 , with Co 3 o 4 According to LaCoO 3 Weigh the stoichiometric ratio in sequence, put it into a 100ml ball mill jar, add an appropriate amount of CH 3 CH 2 OH, ball milled for 6h, and then dried under an infrared lamp to obtain a gray powder. Put the gray powder in a high-temperature furnace, calcinate it in the air at 900 °C for 11 h, and cool it down to room temperature naturally to obtain black LaCoO 3 powder. The prepared LaCoO 3 Add the powder into the ball mill jar, and then add 25% (accounting for LaCoO 3 mass fraction) of soluble starch as a pore-forming agent, CH 3 CH 2 OH was used as a solvent, and after ball milling for 50 min, it was dried under an infrared lamp, and after drying, 3% (accounting for LaCoO 3 The total mass fraction of powder and starch) polyvinyl butyral as a binde...

Embodiment 3

[0072] (1) Electrode material Ag / La 0.5 Sr 0.5 CoO 3‐δ (La 1‐x Sr x CoO 3‐δ , x=0.5, referred to as: LSC0.5) preparation: first La 2 o 3 Calcined at 1100°C for 3h to remove the moisture; then the calcined La 2 o 3 , with SrCO 3 、Co 3 o 4 According to La 0.5 Sr 0.5 CoO 3‐δ Weigh the stoichiometric ratio in sequence, put it into a 100ml ball mill jar, add an appropriate amount of CH 3 CH 2 OH, ball milled for 20 hours, and then dried under an infrared lamp to obtain a gray powder. Place the gray powder in a high-temperature furnace, calcinate at 1000°C for 9 hours, and cool down to room temperature naturally to obtain black LSC0.5 powder. Add the prepared LSC0.5 powder into the ball mill jar, and then add 10% (accounting for the mass of LSC0.5 powder) soluble starch as a pore-forming agent, CH 3 CH 2 OH was used as a solvent, and after ball milling for 50 minutes, it was dried under an infrared lamp. After drying, 5% (accounting for the total mass fraction of L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com