Production method of electrode of supercapacitor

A supercapacitor and electrode technology, which is applied in the field of supercapacitor electrode preparation, can solve the problems of slow preparation speed, low preparation efficiency, complex preparation of supercapacitor electrodes, etc., and achieve the effect of short preparation period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

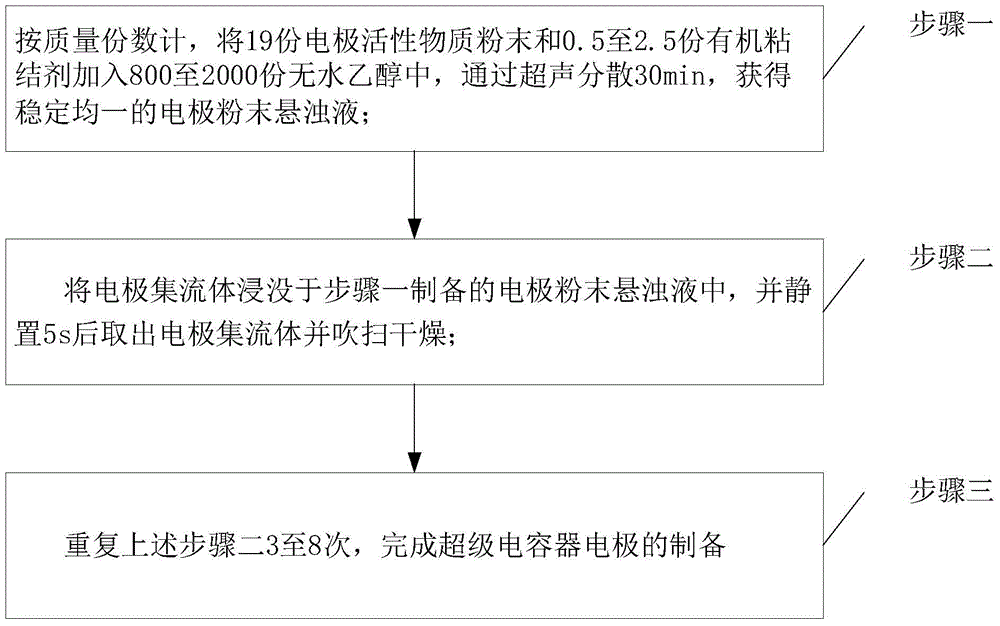

[0036] Specific implementation mode one: see figure 1 Illustrate this embodiment, the preparation method of a kind of supercapacitor electrode described in this embodiment, it comprises the steps:

[0037] Step 1: Add 19 parts of electrode active material powder and 0.5 to 2.5 parts of organic binder into 800 to 2000 parts of absolute ethanol in parts by mass, and disperse by ultrasonic for 30 minutes to obtain a stable and uniform electrode powder suspension;

[0038] Wherein, the organic binder is a terpineol solution of ethyl cellulose, and the mass fraction of ethyl cellulose in the organic binder is 80% to 95%;

[0039] Step 2: Submerge the electrode collector in the electrode powder suspension prepared in Step 1, and let it stand for 5 seconds, then take out the electrode collector and blow dry;

[0040] Step 3: Repeat the above step 2 3 to 8 times to complete the preparation of the supercapacitor electrode.

[0041]In this embodiment, the electrode powder suspension i...

specific Embodiment approach 2

[0044] Specific embodiment two: the difference between this embodiment and the preparation method of a supercapacitor electrode described in specific embodiment one is that the electrode active material powder is manganese dioxide powder, ruthenium oxide, nickel oxide, nickel hydroxide , cobalt oxide, vanadium oxide, tin oxide or iron oxide.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and the preparation method of a supercapacitor electrode described in specific embodiment one is that the electrode current collector is a planar porous nickel foam, and the planar porous nickel foam is 5cm long. , the width is 5cm, the thickness is 1.5mm, and step 11 is added between step 1 and step 2;

[0046] Step 11: Place the planar porous nickel foam in absolute ethanol for 5 minutes for ultrasonic cleaning, then wash it with deionized water, and finally immerse it in acetone for ultrasonic dispersion for 5 minutes, blow dry it, and dry it in the air for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com