Automobile electronic control two-wheel and four-wheel drive switching clutch

A four-wheel drive switching and clutch technology, applied in the field of clutches, can solve problems such as high fuel consumption and noise, complicated operation, and complex structure of automatic switching methods, and achieve the effect of reducing noise and fuel consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

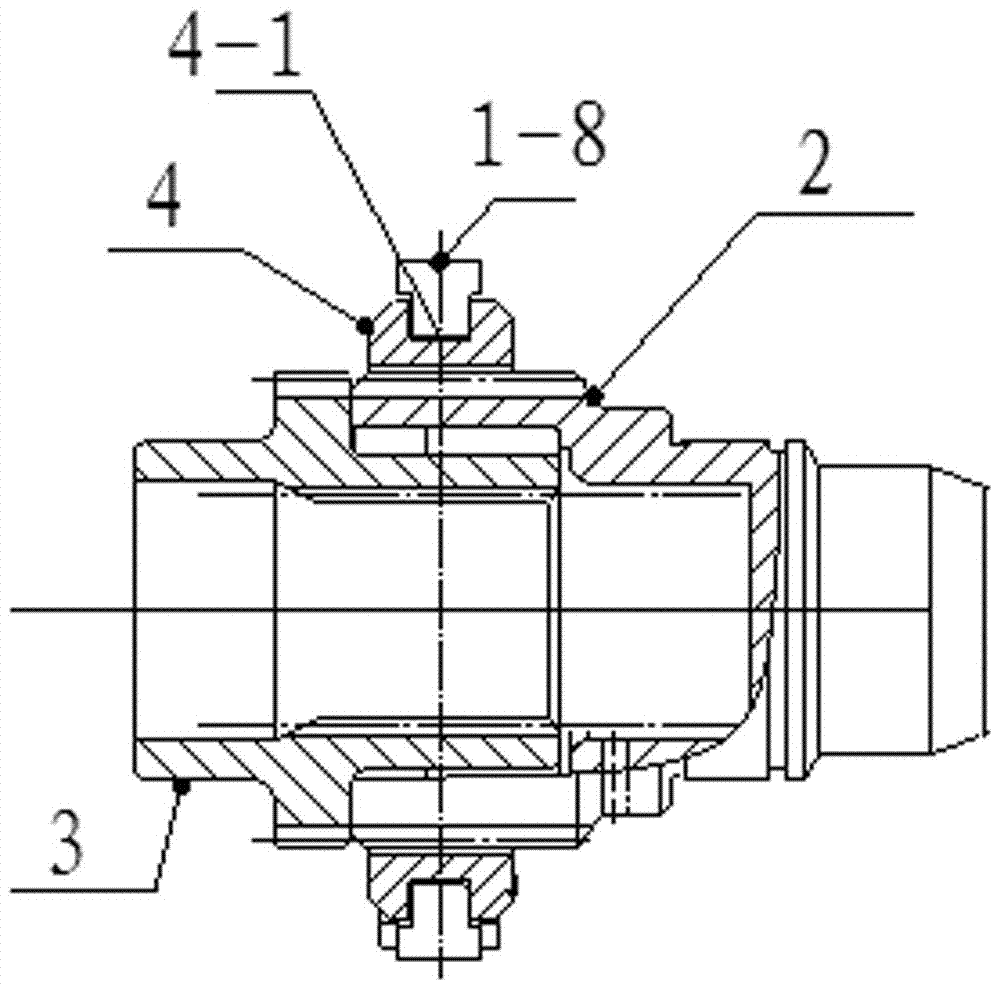

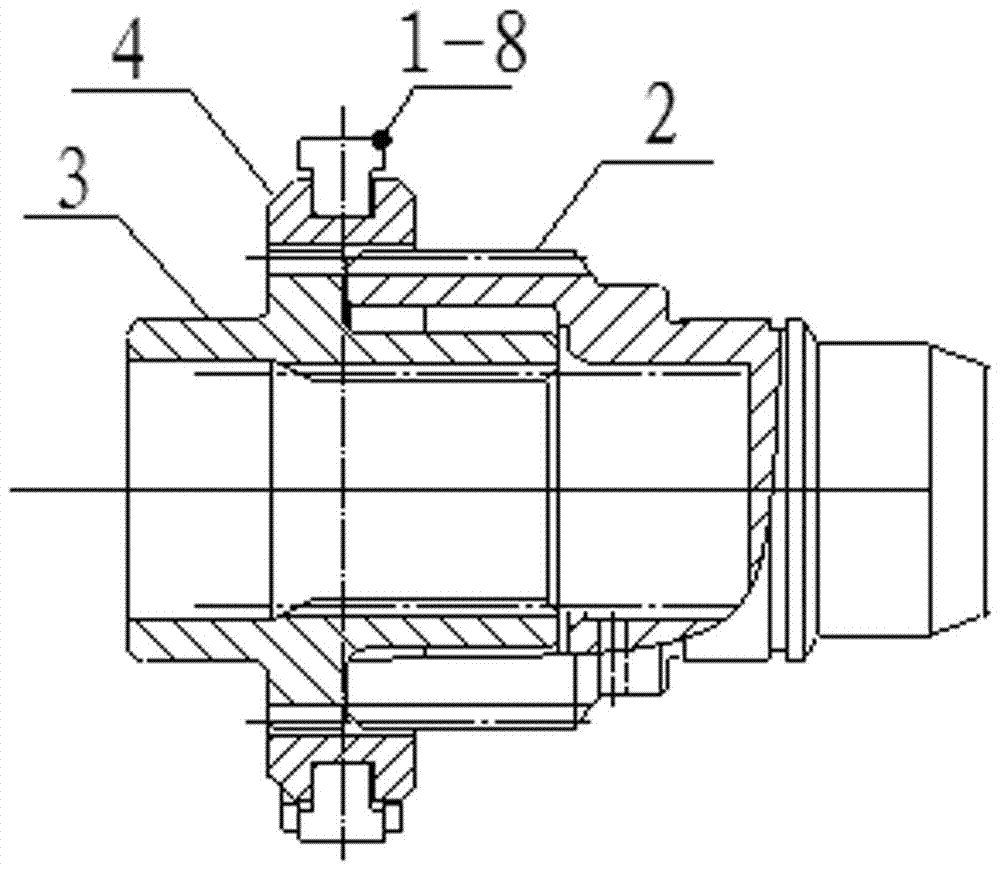

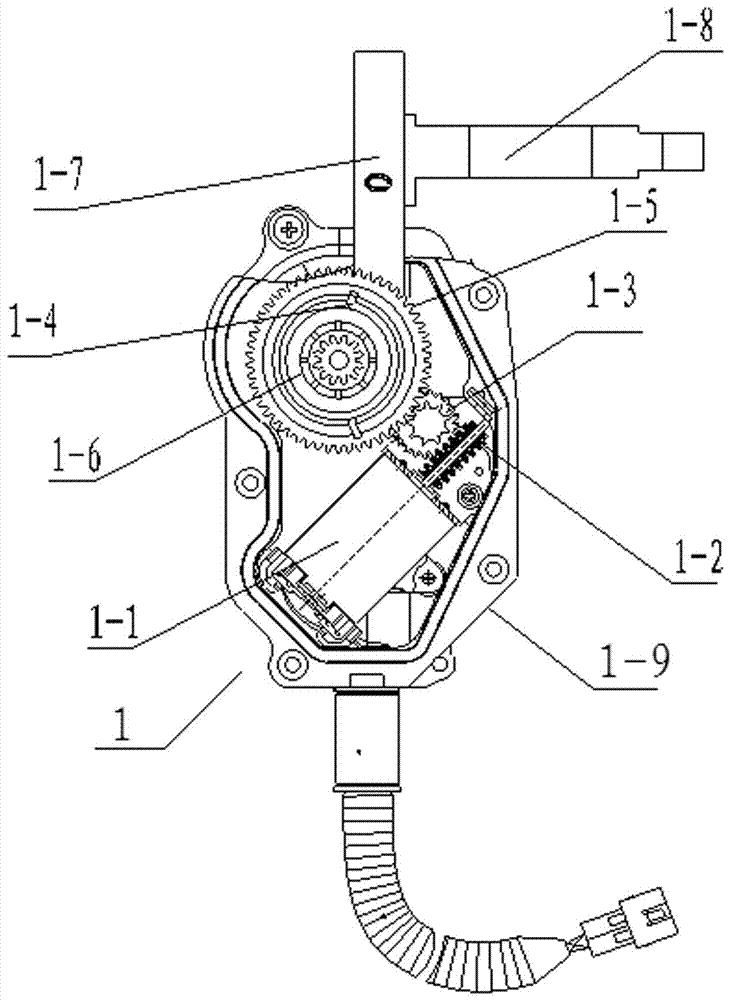

[0021] Such as Figure 1-2 As shown, one of the specific embodiments of an automobile electronically controlled two-wheel drive and four-wheel drive switching clutch includes a long half shaft 2 and a mechanical wheel 3. The long half shaft and the mechanical wheel have the same modulus and are connected together. The long half shaft 2 is covered with a slidable shift fork sleeve 4, and when the shift fork sleeve is located on the long half shaft, it is in a two-drive state (refer to figure 1 ), when the shift fork sleeve is set on the long axle shaft and the mechanical wheel at the same time, it is in the four-wheel drive state (refer to figure 2 ). In the present invention, the outer circumference of the shift fork sleeve 4 is provided with an annular shifting groove 4-1, and the shifting groove 4-1 is moved by the electric control shift fork assembly 1, and is inserted through the shift fork of the electric control shift fork assembly 1. In the shifting slot 4-1, the shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com