Down hole continuous screen pipe hole protection method for coal mine

A technology for screen pipes and coal mines, which is applied in mining equipment, earthwork drilling, boreholes/well parts, etc., can solve the problems of low compressive strength of screen pipes, high labor intensity of workers, and low efficiency of lowering screen pipes, achieving valuable Time and safety assurance, manpower saving, and the effect of reducing the probability of gas overrun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

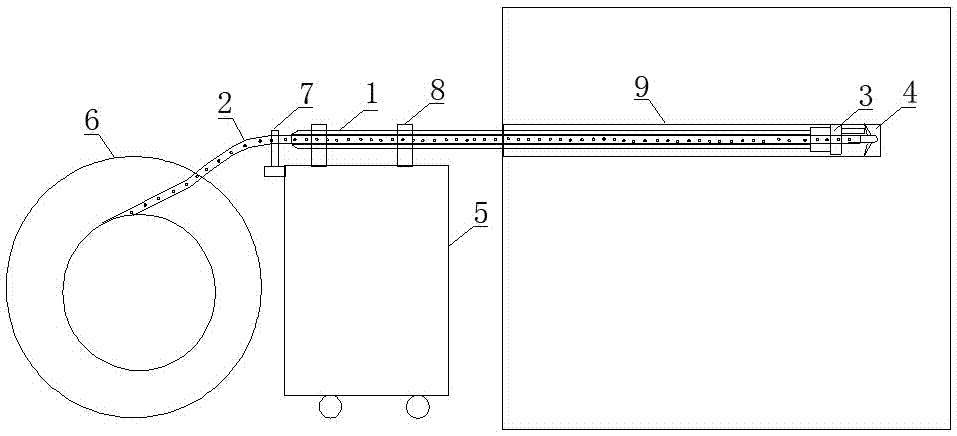

[0025] Such as figure 1 Shown, a kind of coal mine downhole continuous screen pipe protection hole method of the present invention comprises the following steps:

[0026] 1) Move the drilling rig, lower screen pipe drill pipe, lower screen pipe drill bit, hole sticking device, pipe feeder, continuous screen pipe, reel and materials to the drilling construction site, and roll the continuous screen pipe on the cylinder On the reel, install the card hole device at the end of the continuous screen pipe; the reel is connected with the bracket through the central shaft, and the reel can rotate around the axis. The selected continuous screen has good flexibility, and also has a certain hardness and bending resistance;

[0027] 2) In the construction of soft coal, drilling along or through layers, special drill pipes and drill bits are used for drilling, the inner diameter of the drill pipe is 30-50mm, and the middle part of the drill bit can be opened or fallen off;

[0028] 3) Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com