Large channel bending portion of endoscope insertion tube

A technology of inserting a tube and a large channel, applied in the field of endoscopy, can solve the problems of reducing the effective inner diameter of the snake bone, difficulty in enlarging the working channel, and reducing the space utilization rate of the snake bone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

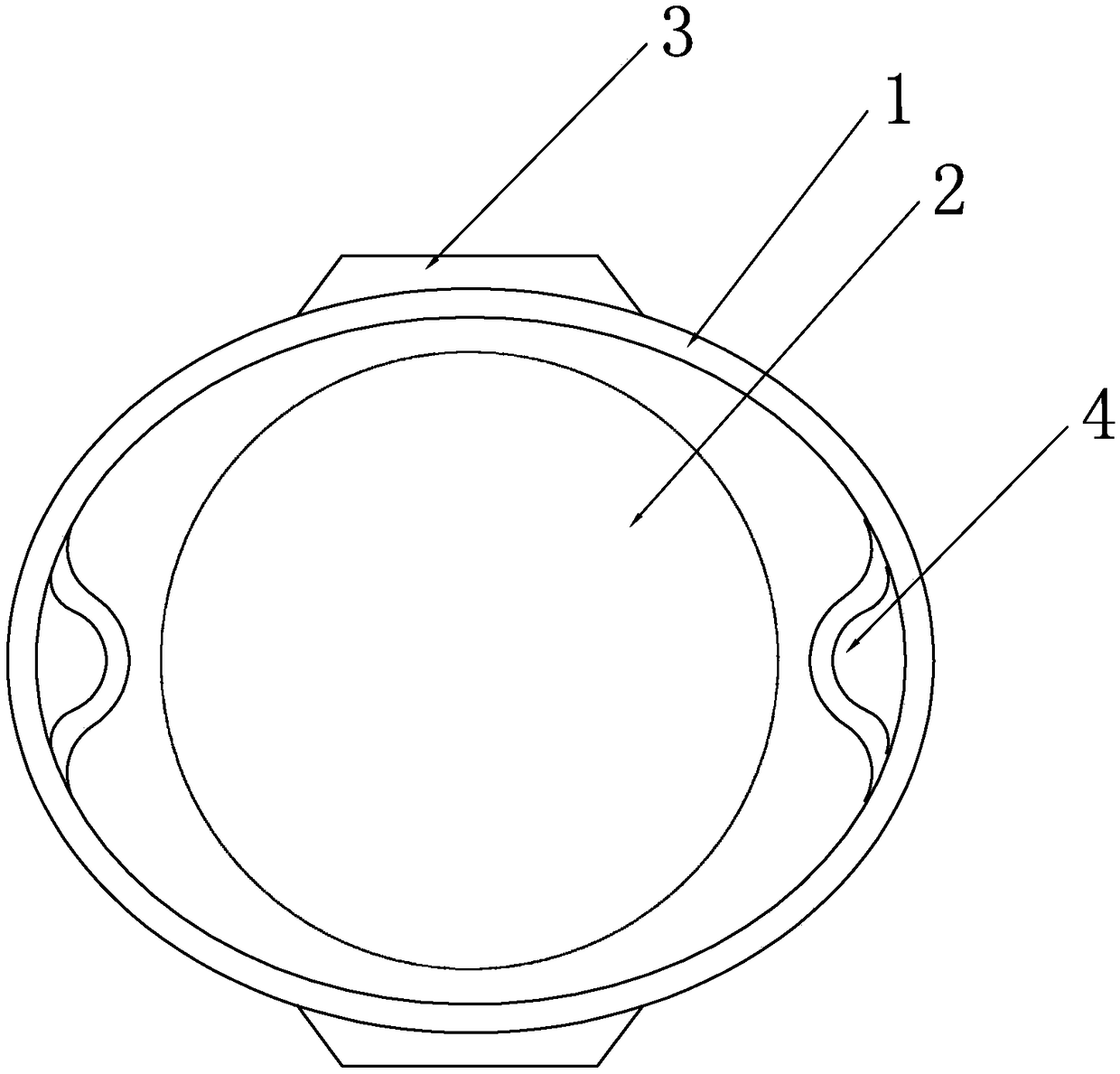

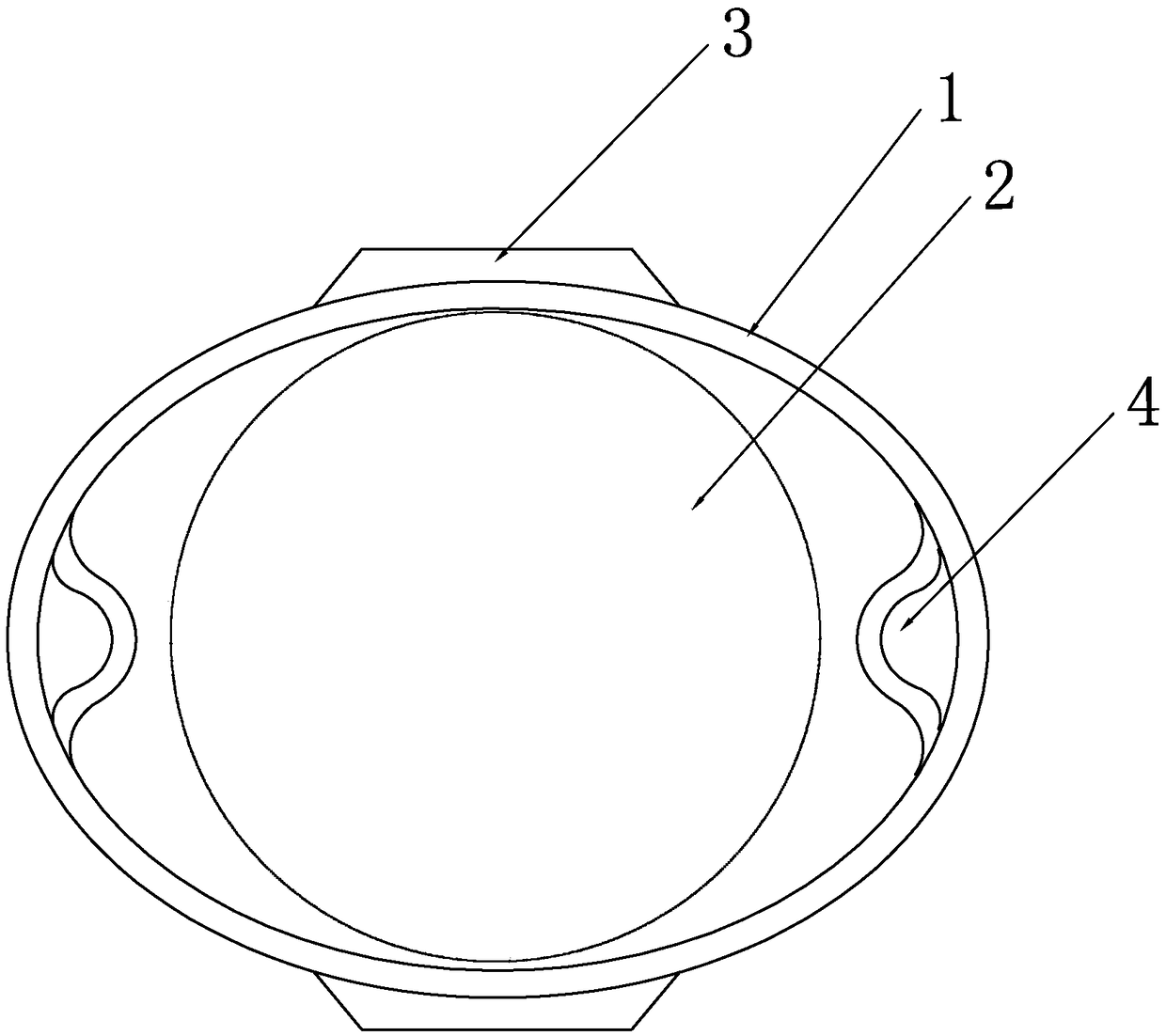

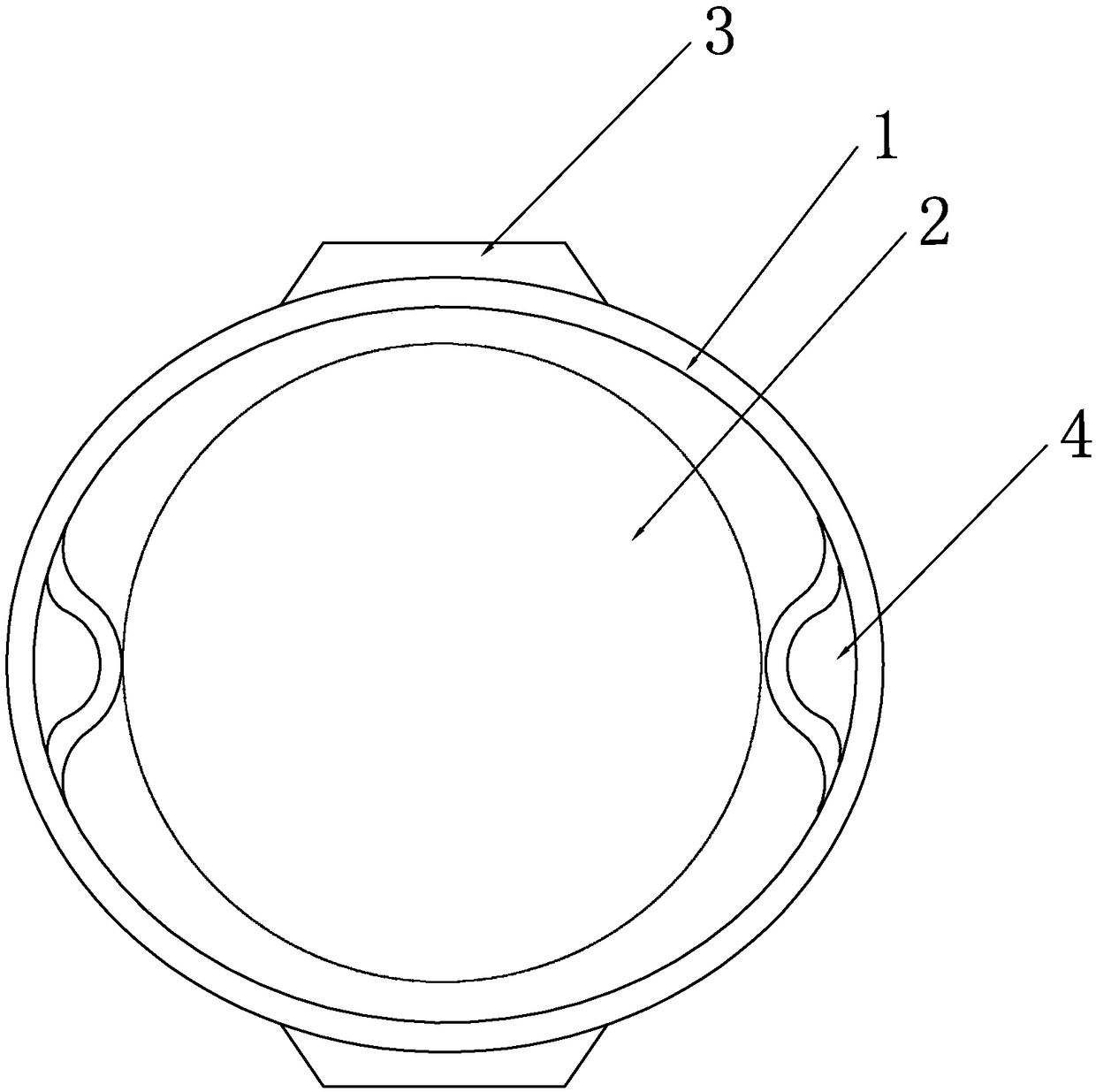

[0019] see figure 1 , a large channel bending portion of an endoscope insertion tube of the present invention includes a snake bone joint tube 1 and a working channel 2 disposed in the snake bone joint tube 1, and the snake bone joint tube 1 includes a plurality of sequentially hinged Snake bone joints, the inner two ends of each snake bone joint are provided with traction holes or traction grooves for the traction wire to pass through. This embodiment is the traction hole 4. Oval, the traction holes are arranged at both ends of the major axis of the cross section of the snake joint tube 1, and the cross section of the working channel 2 is circular.

[0020] Wherein, two adjacent snake bone joints are hinged together by a hinge 3, and the hinge 3 is located outside the snake bone joint, and two adjacent snake bone joints are hinged together by two hinges 3, the two The two hinge parts 3 are respectively located at the two ends of the extension line of the minor axis of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com