Beam-string-structured double-curved arched roof board beam structure

A roof panel and arched technology, applied in the direction of roof, building components, building structure, etc., can solve the problem of high-altitude welding workload of portal rigid frame light steel structure, poor anti-corrosion, fire-proof and thermal insulation performance, load-bearing To solve problems such as low force, to achieve the effect of shortening the construction period, fast construction speed, and improving the waterproof performance of the roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

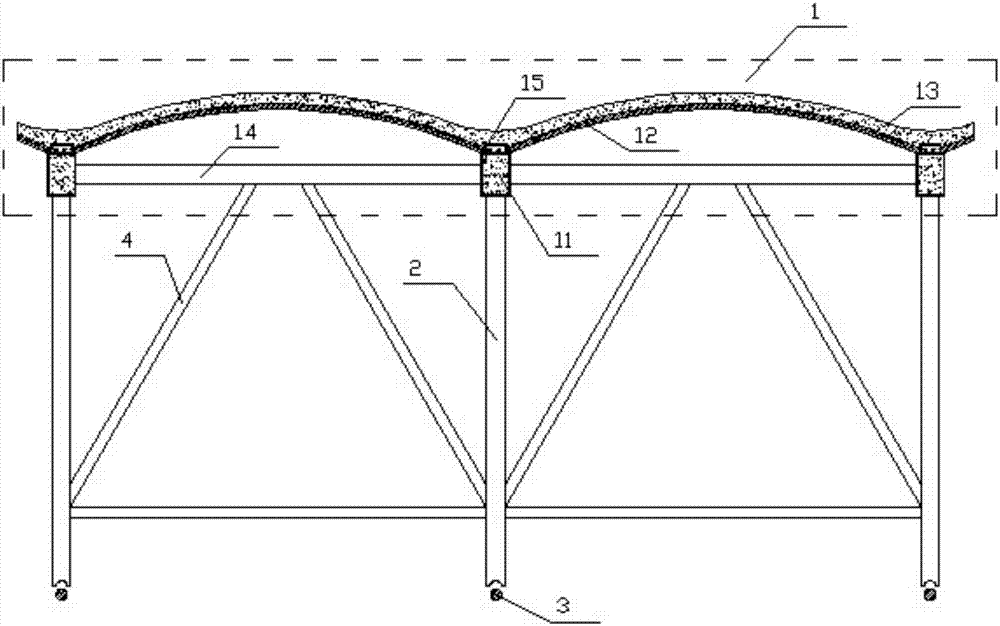

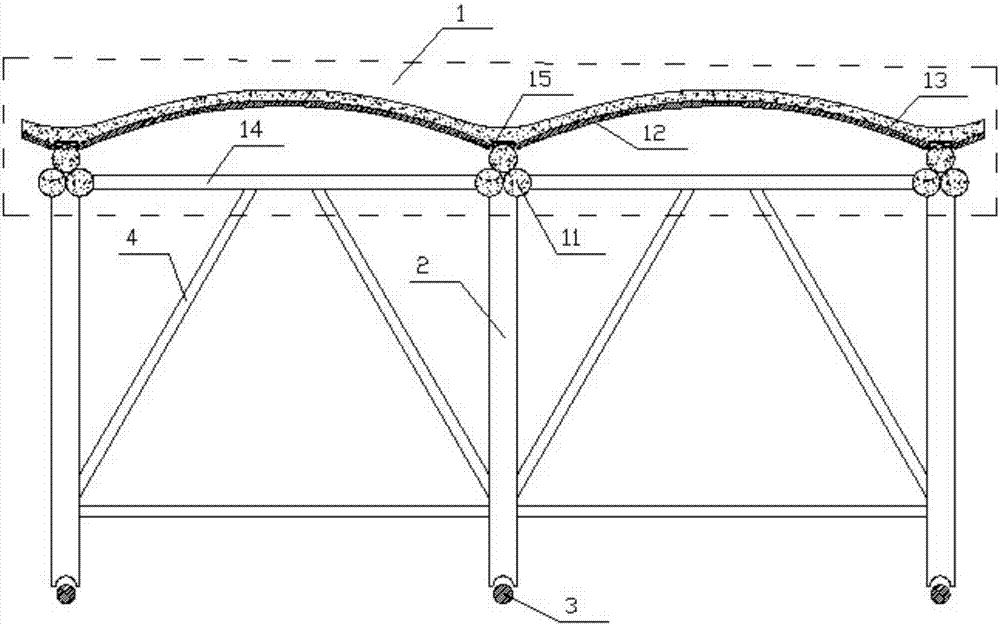

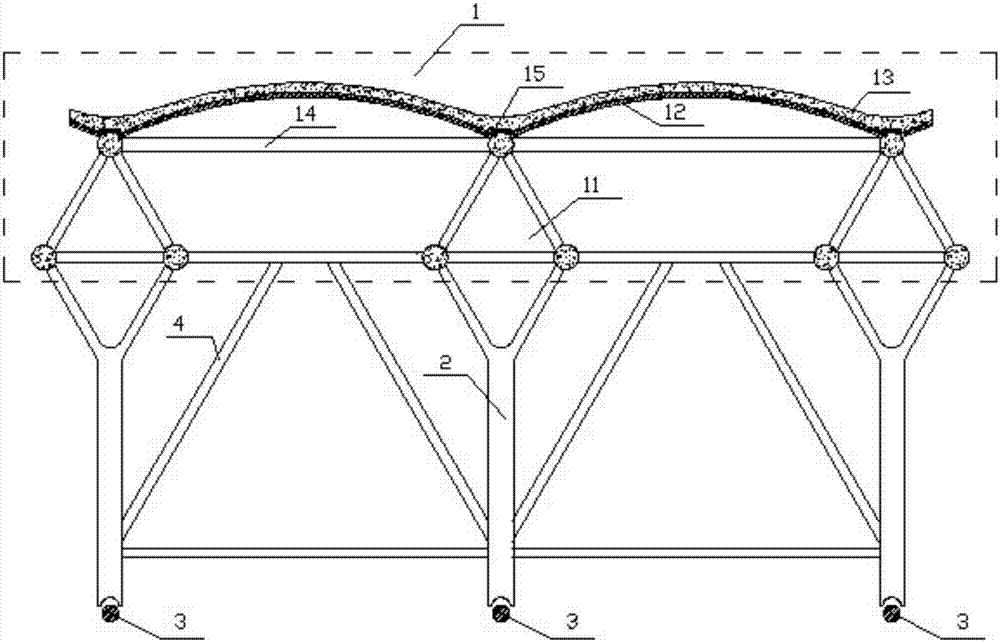

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-Figure 4 As shown, a chord type hyperbolic arch roof panel beam structure of the present invention is composed of a roof hyperbolic arch 1 , struts 2 , zigzag prestressed steel cables 3 and transverse steel supports 4 . Among them, the roof hyperbolic arch slab 1 is composed of steel pipe concrete arch rib 11, profiled steel plate microbending arch wave 12, concrete arch slab 13, connecting beam 14 and channel steel connector 15, and the top of steel pipe concrete arch rib 11 is provided with channel steel connector 15. The connecting beam 14 is arranged between the concrete-filled steel tube arch ribs 11, and the profiled steel plate micro-bending arch wave 12 is laid between the steel tube concrete arch ribs 11, and the concrete arch plate 13 is poured on the profiled steel plate micro-bending arch wave 12; At least three vertical struts 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com