Washing machine silencing method and washing machine

A washing machine and noise reduction technology, which is applied in other washing machines, washing devices, textiles and paper making, etc., can solve the problems of rising cost, complicated structure design, prolonged production cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

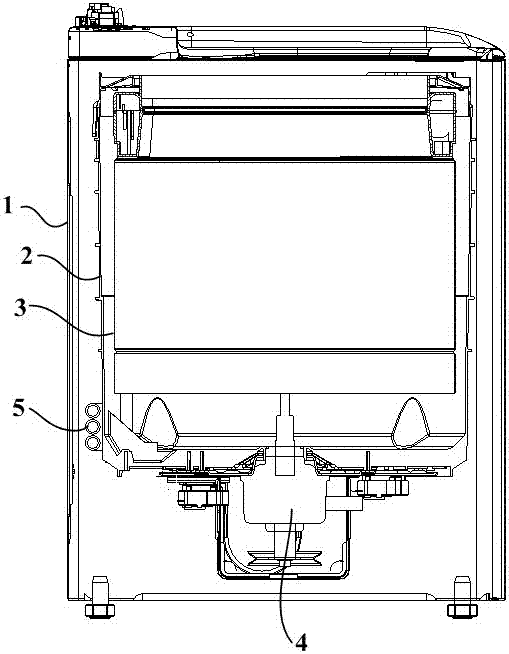

[0026] As a kind of clothing washing equipment, the washing machine is usually equipped with main components such as an outer casing 1, an outer tub 2, an inner tub 3 and a motor 4, such as figure 1 shown. Wherein, the inner tub 3 is used as a washing tub, is arranged in the outer tub 2, and is built in the outer casing 1 together with the motor 4 . As the power part of the washing machine, the motor 4 is generally located under the outer tub 2 (for a pulsator washing machine) or behind the outer tub 2 (for a drum washing machine). It not only needs to drive the inner tub 3 to rotate, but also for the pulsator washing machine. Say, also need to drive the pulsator rotation in the inner bucket 3, finish washing operation.

[0027] During the use of the washing machine, due to the inconsistent water absorption capacity and material of the laund...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com