Pump components, compressors and air conditioners

A component and pump body technology, applied in pump components, machines/engines, liquid fuel engines, etc., can solve problems such as axial unbalanced overturning moment, refrigerant leakage, and detachment, so as to reduce the noise of the whole machine, improve reliability, The effect of improving the performance of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

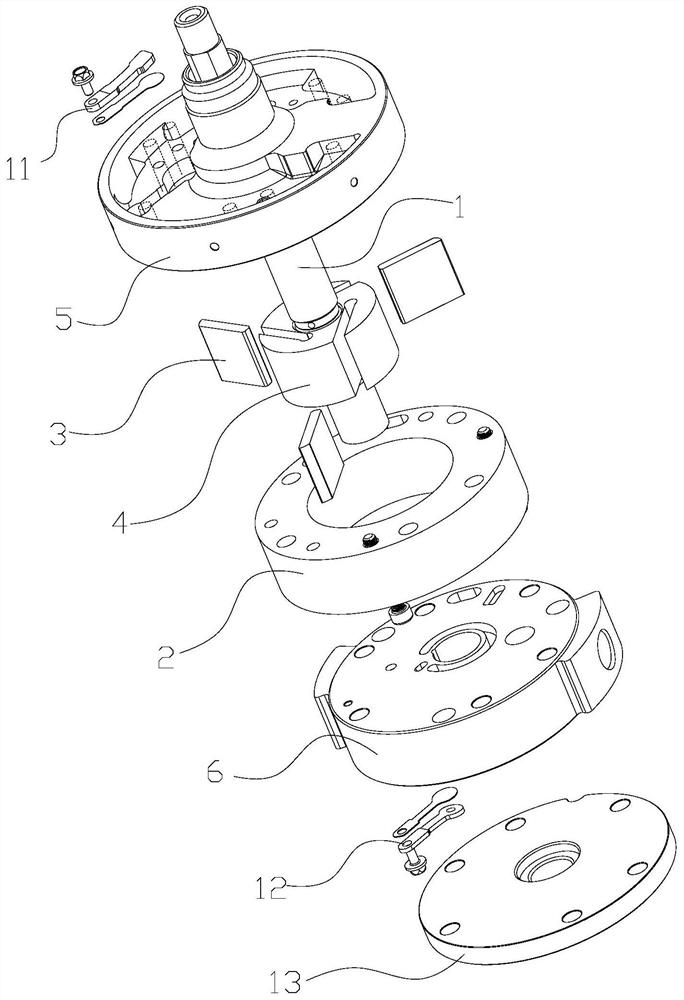

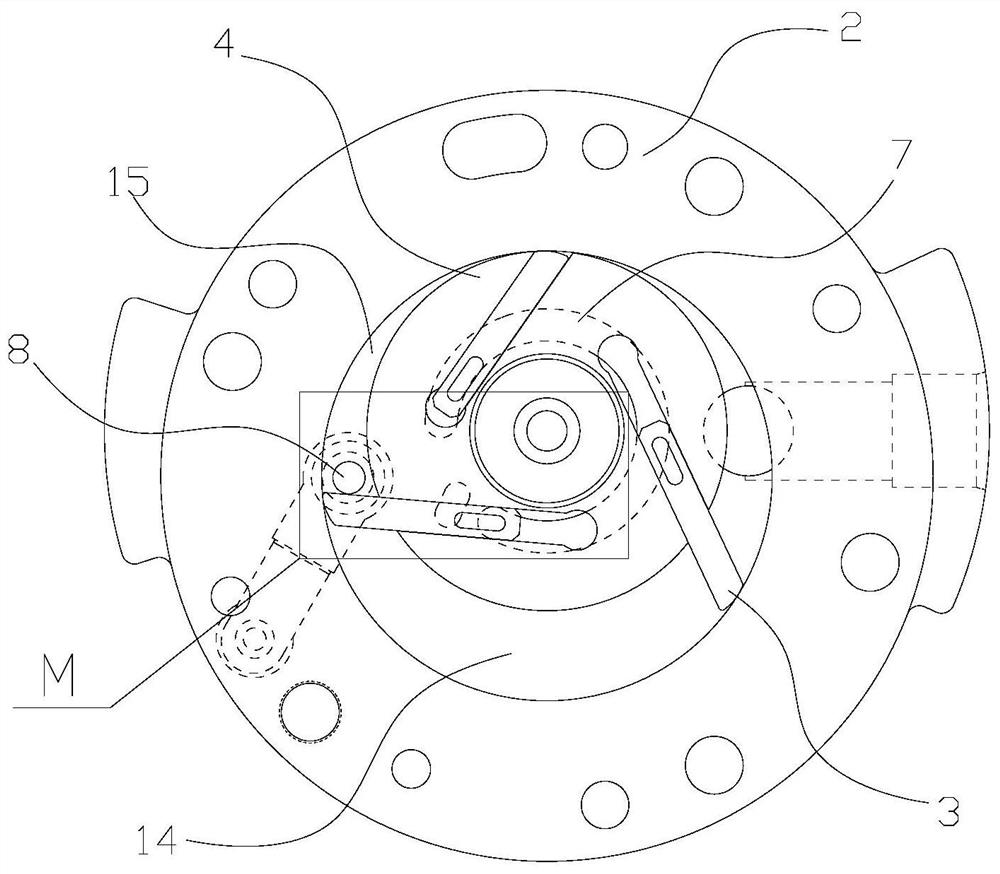

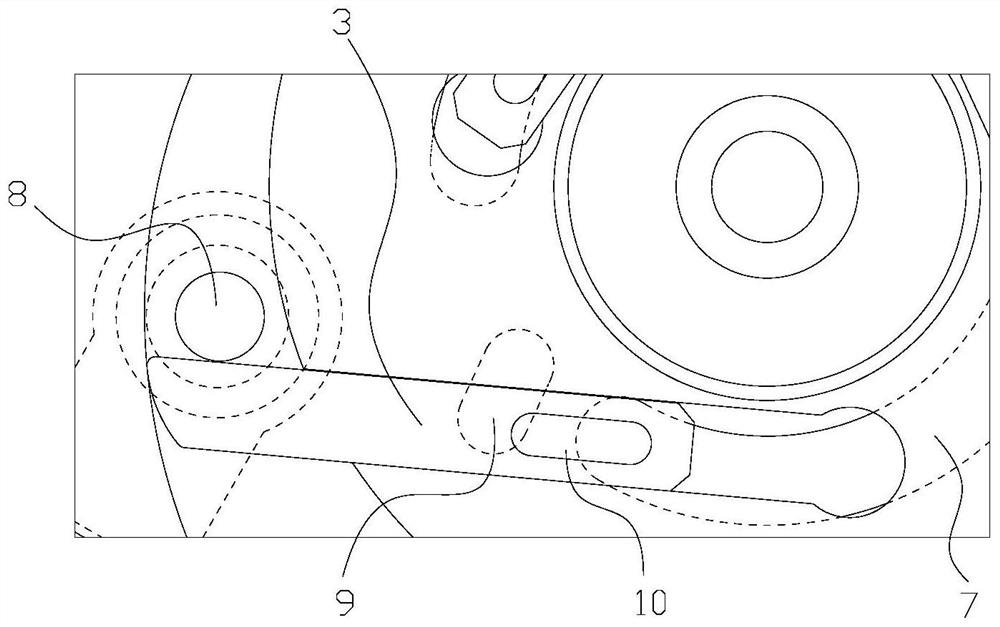

[0037] see in conjunction Figure 1 to Figure 14 As shown, according to the embodiment of the present application, the pump body assembly includes a main shaft 1, a flange, a cylinder 2 and a sliding piece 3, the main shaft 1 includes a convex portion 4, and a plurality of sliding pieces 3 are arranged on the convex portion 4 at intervals along the circumferential direction, The flange is provided with a back pressure oil groove and an exhaust port, and a pressure balance groove is also arranged on the flange. The pressure balance groove can communicate with the back pressure oil groove when the slide plate 3 moves to the position of the exhaust port, and when the slide plate 3 moves away from One side of the exhaust port exerts an axial force to balance the moment that the sliding vane 3 receives at the exhaust port.

[0038] During the working process of the pump body assembly, when the sliding vane 3 slides to the position of the exhaust port, it will be subjected to the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com