Continuous fiber-reinforced thermoplastic resin prepreg thread and preparation method thereof, and apparatus used in preparation method

A technology for enhancing thermoplasticity and thermoplastic resin, applied in the field of composite materials, can solve problems such as poor mechanical properties of products and poor bonding between layers, and achieve the effects of improving mechanical properties, increasing melt index, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

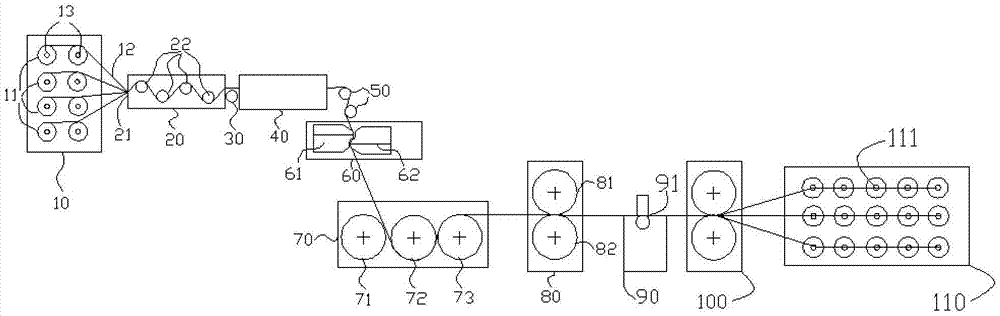

[0059] A method for preparing a continuous glass fiber reinforced polypropylene prepreg line, comprising the following steps:

[0060] (1) The continuous fiber roll 11 is installed on the spindle support 13 of the spinning frame 10, and the continuous fiber roll is carefully pulled through the guide hole installed on the creel 10, and the fiber drawn out through the guide hole is passed through the tension device 20. The thread discharge port 21 makes the fibers parallel and evenly arranged to avoid crossing and abrasion between the fibers. Then the continuous fiber bundles 12 arranged in parallel pass through the tension adjustment roller 22, apply a certain tension to the fibers to ensure the preliminary dispersion of the fibers, and eliminate the static electricity generated by the static elimination device 30; the continuous fiber roll 11 is a continuous glass fiber roll.

[0061] The spinning frame 10 is provided with a horizontally rotating spindle support 13, and the sp...

Embodiment 2

[0072] A preparation method for continuous aramid fiber reinforced polyethylene terephthalate prepreg line, comprising the following steps:

[0073] (1) The continuous fiber roll 11 is installed on the spindle support 13 of the spinning frame 10, and the continuous fiber roll is carefully pulled through the guide hole installed on the creel 10, and the fiber drawn out through the guide hole is passed through the tension device 20. The thread discharge port 21 makes the fibers parallel and evenly arranged to avoid crossing and abrasion between the fibers. Then the continuous fiber bundles 12 arranged in parallel pass through the tension adjustment roller 22, apply a certain tension to the fibers to ensure the initial dispersion of the fibers, and eliminate the static electricity generated by the static elimination device 30; the continuous fiber roll 11 is a continuous aramid fiber roll.

[0074] (2) The continuous fiber tape obtained in step (1) is preheated to a temperature o...

Embodiment 3

[0081] A method for preparing a continuous carbon fiber reinforced polycarbonate prepreg line, comprising the following steps:

[0082](1) The continuous fiber roll 11 is installed on the spindle support 13 of the spinning frame 10, and the continuous fiber roll is carefully pulled through the guide hole installed on the creel 10, and the fiber drawn out through the guide hole is passed through the tension device 20. The thread discharge port 21 makes the fibers parallel and evenly arranged to avoid crossing and abrasion between the fibers. Then the continuous fiber bundles 12 arranged in parallel pass through the tension adjustment roller 22, apply a certain tension to the fibers to ensure the preliminary dispersion of the fibers, and eliminate the static electricity generated by the static elimination device 30; the continuous fiber roll 11 is a continuous carbon fiber roll.

[0083] (2) The continuous fiber tape obtained in step (1) is preheated to a temperature of 300°C th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com