Polyphosphoric acid production method using device for making acid from phosphorous slurry

A technology of polyphosphoric acid and mud phosphorus, applied in phosphorus oxo acid, condensed phosphoric acid and other directions, can solve the problems of weak market competitiveness, many application restrictions, low mud phosphoric acid, etc., achieves significant economic benefits, simplifies process flow, operation The effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

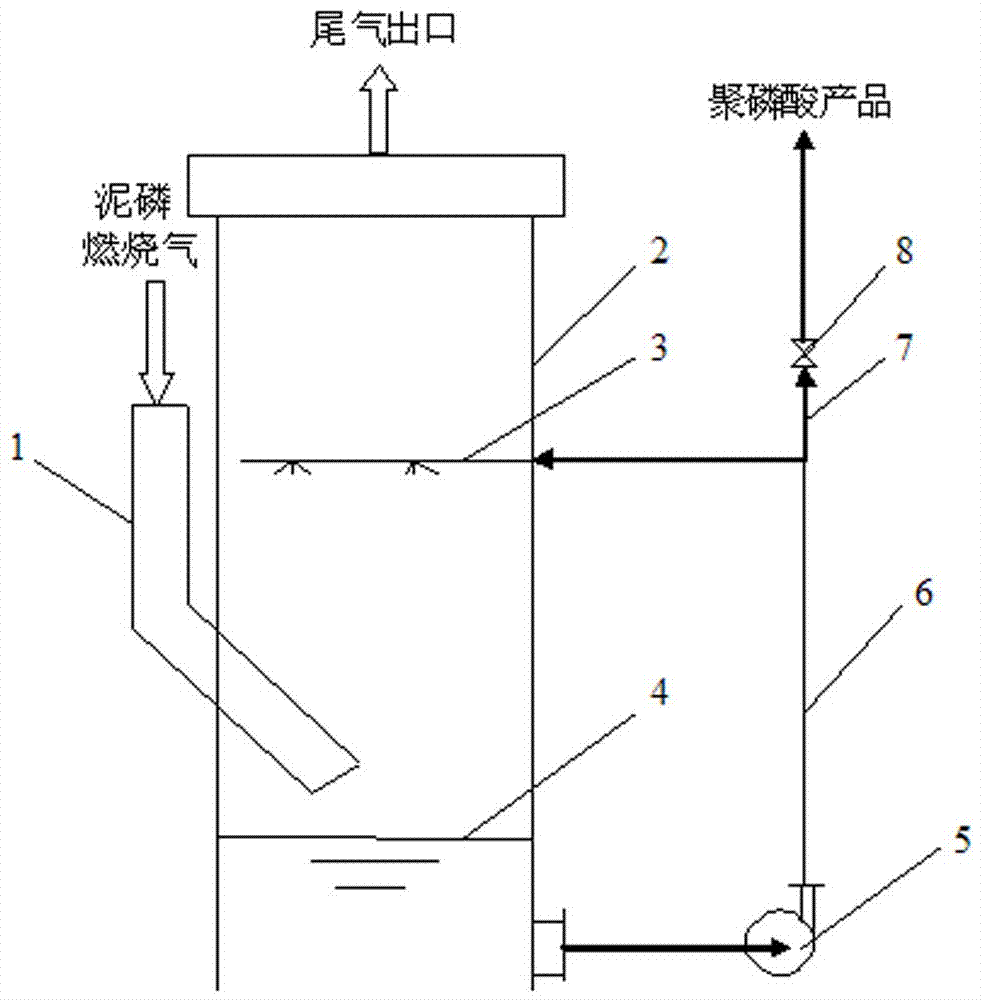

[0011] A new method of producing polyphosphoric acid using a mud phosphorus acid plant, sending mud phosphorus, a by-product of yellow phosphorus production, into the mud phosphorus tank, heating to 70°C to 80°C, stirring and mixing evenly, pumping into the nozzle in the combustion tower, and compressing Air atomization, oxidation reaction with excess combustion air of 2.0 times in the combustion tower and reburning tower to generate P 2 o 5 The high-temperature combustion gas of mud phosphorus and water steam, the temperature is controlled at 1100°C, enters the lower part of the hydration tower 2 through the inlet pipe 1 of the high-temperature combustion gas of mud phosphorus, and countercurrently hydrates the circulating phosphoric acid in the phosphoric acid spray pipe 3 to control the circulating spray The temperature of phosphoric acid is 80°C, the height of circulating phosphoric acid liquid level 4 and mud phosphorus high-temperature combustion gas inlet pipe 1 is cont...

Embodiment 2

[0013] A new method of producing polyphosphoric acid by using mud phosphorus acid production equipment, ..., oxidation reaction occurs in combustion tower and reburning tower with excess combustion air of 2.3 times, and generates phosphorus containing 2 o 5 The temperature of the high-temperature combustion gas and water vapor is controlled at 1150°C, ..., the temperature of the circulating acid spray is controlled at 90°C, and the height of the circulating acid liquid level 4 and the high-temperature combustion gas inlet pipe 1 of the sludge phosphorus is controlled to 500mm, ... The acid pipe 7 is directly connected to the circulating phosphoric acid pipe 6 at the outlet of the circulating pump 5, and after passing through the valve 8, phosphoric acid with a concentration of about 100% by weight is drawn out. The other content omitted is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0015] A new method of producing polyphosphoric acid using a mud phosphorus acid plant, ..., and an oxidation reaction with an excess of 2.5 times the combustion air in the combustion tower and the reburning tower to generate P 2 o 5 The temperature of the high-temperature combustion gas with water vapor is controlled at 1200°C, ..., the temperature of the circulating phosphoric acid is controlled at 100°C, the height of the circulating acid liquid level 4 and the high-temperature combustion gas inlet pipe 1 of the sludge phosphorus is controlled to 400mm, ... The acid pipe 7 is directly connected to the circulating phosphoric acid pipe 6 at the outlet end of the circulating pump 5, and after passing through the valve 8, phosphoric acid with a concentration of about 105% by weight is drawn out. The other content omitted is the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com