Full-automatic auxiliary stamping equipment for machining packing box base plate holes and operation method

A stamping equipment and hole processing technology, which is applied in the field of hole processing of the bottom plate of the packaging box and automatic auxiliary stamping equipment, can solve the problems of increasing manpower, using a large hammering force, and low work efficiency, so as to reduce labor intensity and ensure Stamping effect, effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

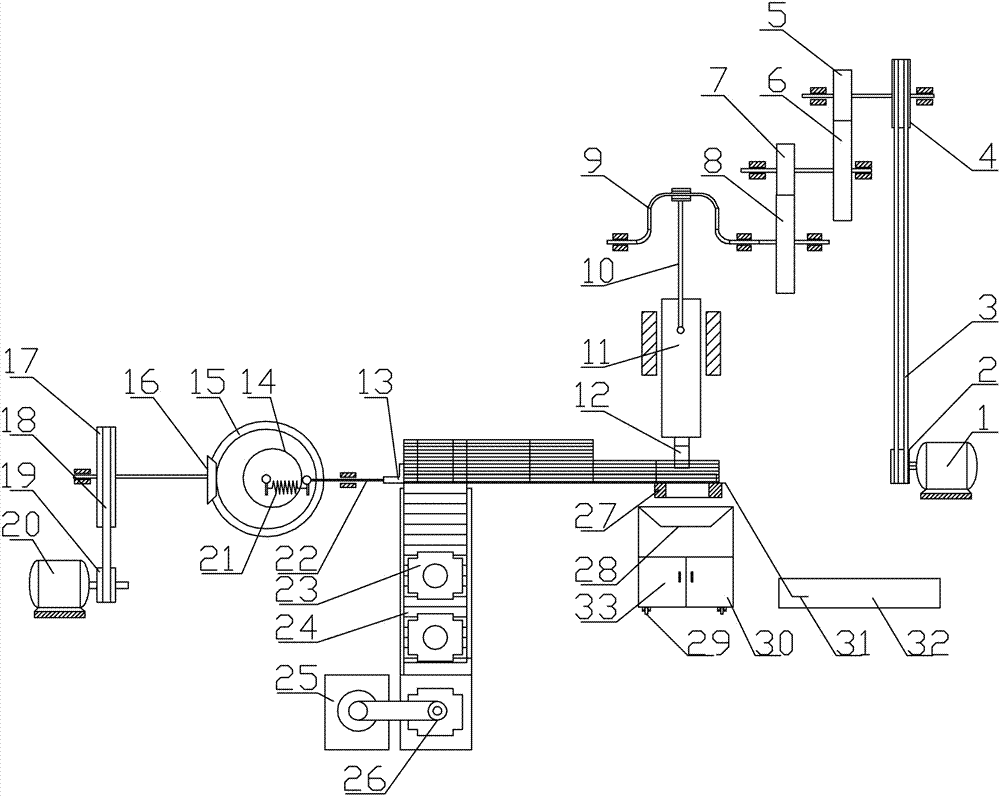

[0036] see Figure 1-2 , the automatic auxiliary stamping equipment for processing the hole of the bottom plate of the packaging box, which includes a punching drive motor 1, a first pulley 2 is installed on the output shaft of the punching drive motor 1, and the first pulley 2 passes through the first The belt 3 and the first driven wheel 4 form a belt drive, and the first gear 5 is installed on the main shaft where the first driven wheel 4 is located, and the first gear 5 is connected to the crankshaft 9 through a multi-stage gear reduction mechanism, and the crankshaft 9 is fitted with a connecting rod 10, the other end of the connecting rod 10 is hinged on the stamping head 11, and the bottom end of the stamping head 11 is equipped with a punching pin 12 which is in contact with the cardboard to be punched, and the punching pin 12 A stamping die 27 is arranged directly below, and the stamping die 27 is installed on the cardboard feeding workbench. A scrap recycling box is ...

Embodiment 2

[0045] Using any fully automatic auxiliary stamping equipment, it includes the following steps:

[0046] The first step is to place the cardboard to be cut directly under the cutting head 26 of the edge cutting device, start the cutting head 26 to cut the position on the cardboard that needs to be punched, and initially cut out the hole position;

[0047] In the second step, the cardboard 23 to be punched that has been cut is transported to the cardboard feeding table docked with it by the transport roller 24;

[0048] The third step is to start the pusher motor 20 of the stepping pusher device, drive the eccentric wheel 14 by the pusher motor 20, drive the ejector rod 22 by the eccentric wheel 14, drive the pusher plate 13 by the pusher rod 22, and drive the pusher plate 13 by the pusher plate 13. Realize the step-by-step promotion of the cardboard 23 to be punched, and the step-by-step movement along the cardboard feeding workbench;

[0049] The fourth step is to start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com