Sprayer for consumable items of 3D printer

A 3D printer and consumable nozzle technology, applied in 3D object support structure, additive processing, additive manufacturing, etc., can solve the problems of affecting the printing effect, easy to block the nozzle of the nozzle, etc., to achieve continuous operation, clean, stable and reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

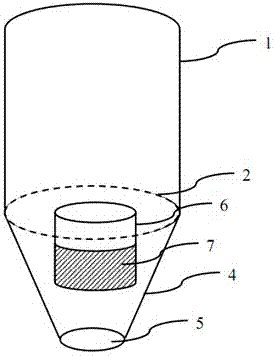

[0023] see figure 1 and 2 , the 3D printer consumable nozzle of the present invention comprises:

[0024] Conduit 1, including a first pipeline for introducing used consumables, a second pipeline for producing low pressure or introducing cleaning gas, and a third pipeline for introducing cleaning liquid;

[0025] The nozzle 4 has a frustum-shaped cavity and a spout 5 . The nozzle 4 is located at the lower end of the conduit 1 and has a dividing surface 2 .

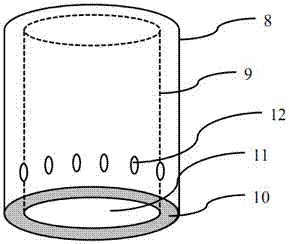

[0026] The feeding pipe 6 extends from the conduit 1 to below the dividing surface 2, and the bottom surface of the feeding pipe is above the nozzle 5, and the lower end surface of the feeding pipe 6 is spaced from the wall surface of the nozzle 4 Open; the feed pipe 6 has two layers of pipe walls 8,9 inside and outside, the inner pipe wall 9 forms an inner chamber, and the outer pipe wall 8 and the inner pipe wall 9 form an outer chamber, and the outer chamber is in the The bottom surface of the tube is closed to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com