Main controller of full-automatic packing belt production machine

A main controller, fully automatic technology, applied in the direction of belts, other household appliances, household appliances, etc., can solve the problems of complex structure of the controller, low mechanical efficiency, low work efficiency, etc., to improve convenience, prolong service life, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

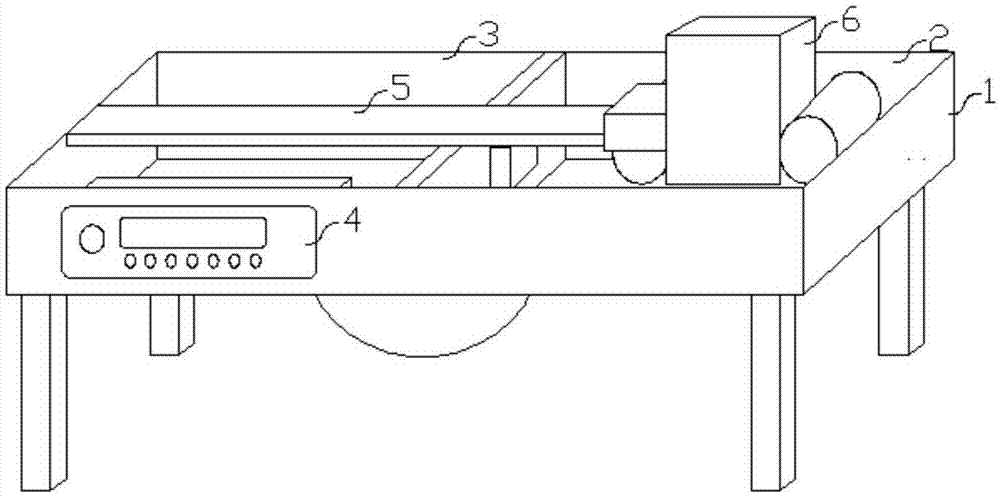

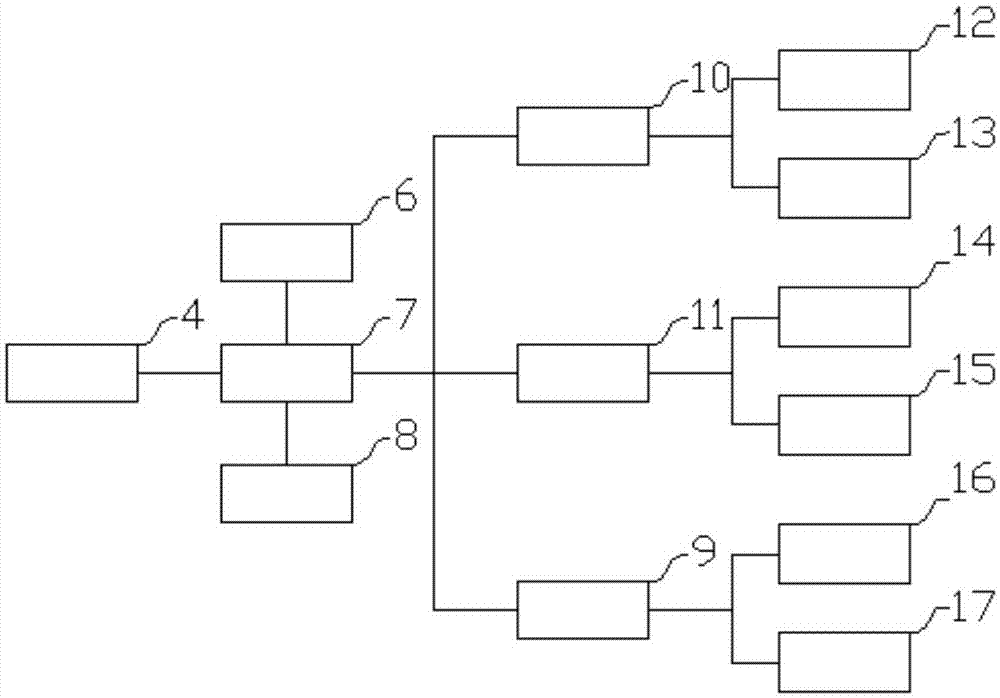

[0016] Example: such as Figure 1-2 As shown, the present invention provides a main controller of a fully automatic production machine for packing belts, including a body 1, a first working chamber 2 and a second working chamber 3, the first working chamber 2 and the second working chamber 3 are arranged in parallel, and the second working chamber A working chamber 2 is built with a servo motor 6, one end of the servo motor 6 is connected to the second working chamber 3 through a transmission belt 5, a control panel 4 is arranged on the surface of the second working chamber 3, and the output end of the control panel 4 is connected to a numerical control device 7, and the numerical control The controller 7 is electrically connected to the servo motor 6, and the output end of the numerical control device 7 is respectively connected to the production system 9, the cooling and setting system 10 and the feeding system 11.

[0017] Further, the production system 9 includes a main ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com