Automatic wiping mechanism and light sorting equipment provided with same

An automatic wiping and spectroscopic technology, applied in the direction of sorting, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, cumbersome process, high cost, etc., and achieve high automation, high cleaning efficiency, high substitution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

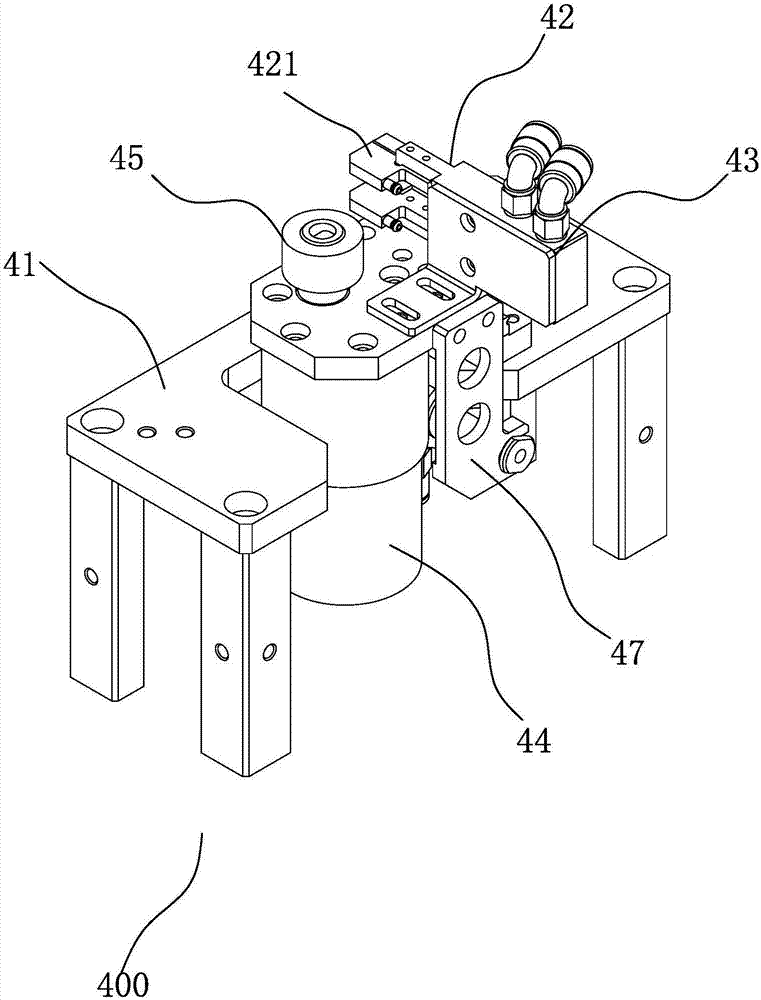

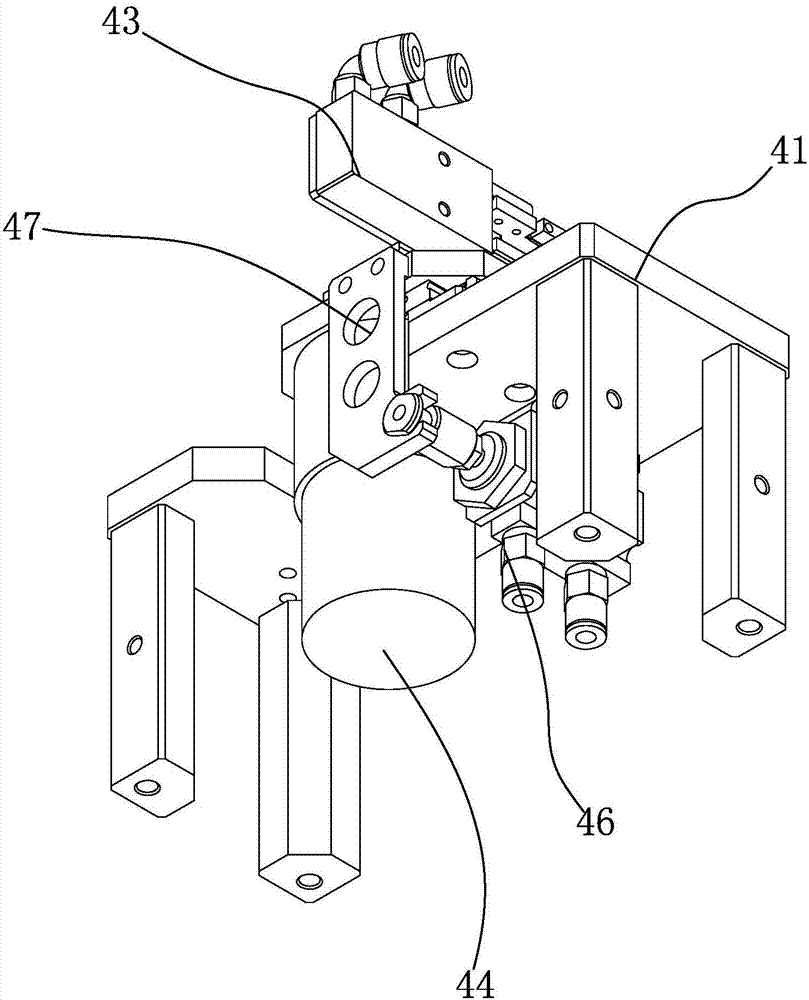

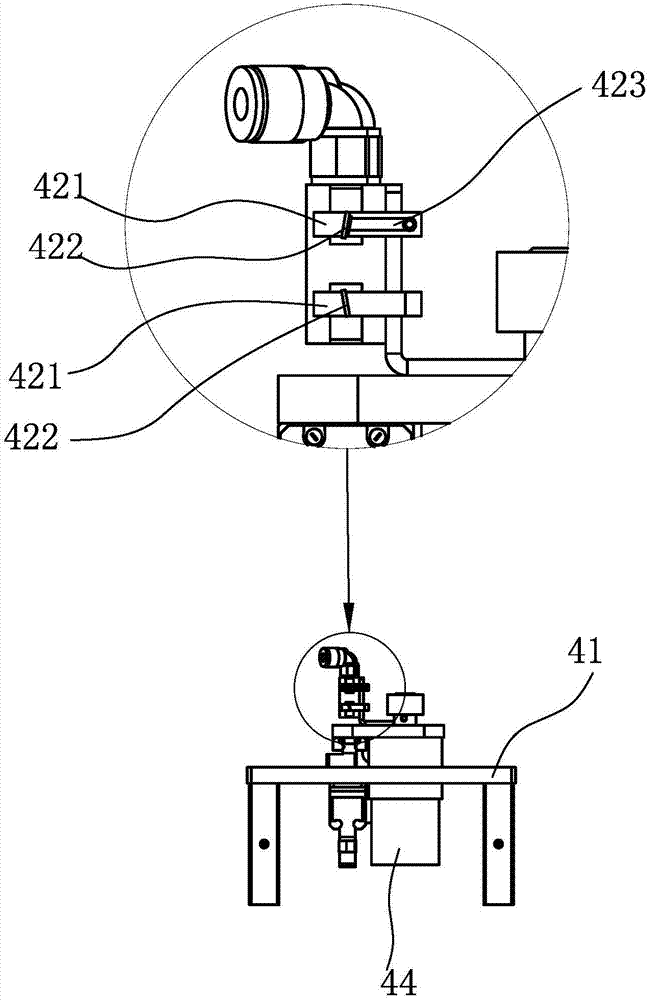

[0033] Such as Figure 1 to Figure 13 Shown is a specific structural view of this embodiment.

[0034] Figure 1 to Figure 3 As shown, an automatic wiping mechanism 400 includes a fixing frame 41 and a wiping assembly 42 slidably coupled to the fixing frame 41 . The wiping assembly 42 is provided with a wiping block 421 for wiping the transparent turntable 23 . The wiping block 421 is provided with a scraper 422 directly in contact with the transparent turntable 23 . The scraper 422 forms an inclination angle of 20°-90° with the moving direction of the transparent turntable 23 .

[0035] There are at least two wiper blocks 421, which are arranged opposite to each other. The wiping block 421 is disposed on the clamping power memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com