Tilting type battery material mixing device

A technology of mixing device and battery material, which is applied in mixers, mixers with rotating containers, transportation and packaging, etc., can solve the problems of delayed production time, troublesome maintenance, etc., and achieves enhanced cooling effect, strong practicability, and protection of ventilation. The effect of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

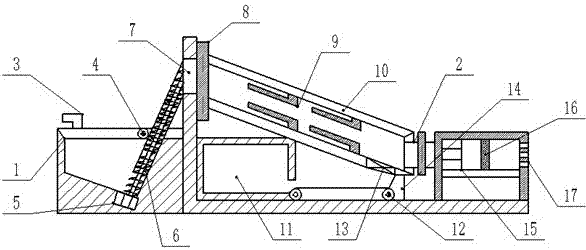

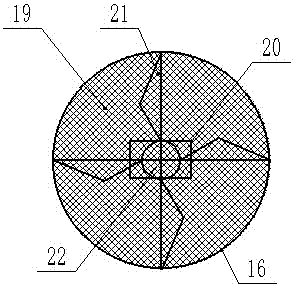

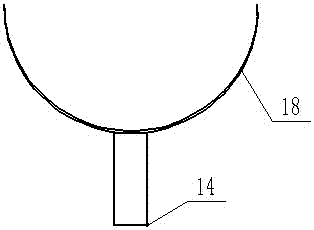

[0017] see Figure 1-3 , an inclined battery material mixing device, including a feeding device 1 and a mixing device 2; the feeding device 1 is provided with a handle 3, a turning point 4, a first motor 5, a conveyor 6 and a material inlet 7; the The handle 3 is fixed at the upper left position of the feeding device 1, and the surface of the handle 3 is surrounded by anti-skid lines; the turning point 4 is fixed at the right end of the handle 3, and the user holds the handle 3 and uses the turning point 4 to open it. The function of the feeding device 1; the first motor 5 is arranged under the feeding device 1, and is fixedly connected to the inner position of the feeding device 1, and the first motor 5 and the bottom plate of the feeding device 1 form an angle of 45 degrees; the The conveyor 6 is fixed vertically at the center position of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com