Probiotic composite composition containing bifidobacterium and lactobacillus acidophilus and application

A composite composition, the technology of Lactobacillus acidophilus, applied in the direction of bifidobacteria, medical preparations containing active ingredients, Lactobacillus, etc., can solve the problems of reduced number of viable bacteria and single composition, so as to reduce the side effects of antibiotics and acid resistance And strong bile resistance, the effect of improving constipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

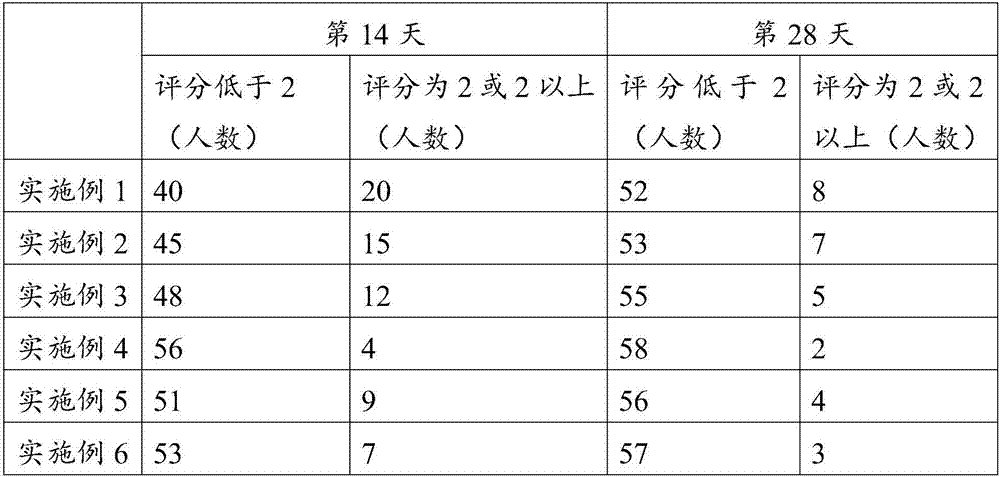

Examples

Embodiment 1

[0056] The steps of making the probiotic complex composition into tablets include:

[0057] (1) Enlarge and cultivate Bb-12 and La-5 bacterial strains with conventional method fermentation;

[0058] (2) Take 1g of strain Bb-12 and 1g of strain La-5, add 1g of inulin, mix, add 15g of resistant dextrin, and mix;

[0059] (3) starch is passed through 80 mesh sieves, and is used as an auxiliary material in the preparation for subsequent use;

[0060] (4) Add the starch obtained in step (3) to the mixed powder obtained in step (2) until the weight is 100g;

[0061] (5) Use a one-step granulator to granulate the above-mentioned mixed powder, pass through a 10-mesh sieve, then add 0.4% magnesium stearate, use a conventional tablet press to compress tablets (the specification is 1g / tablet), and then coat (conventional film-coated), bottled.

Embodiment 2

[0063] This example uses the same method as in Example 1 to prepare tablets, except that the amount of each component is changed to 3g of strain Bb-12, 3g of strain La-5, 5g of inulin, 23g of resistant dextrin, and starch as the carrier. The tablet specification is 1g / tablet.

Embodiment 3

[0065] The present embodiment adopts the substantially same method as embodiment 1 to prepare capsules. The difference is that the dosage of each component becomes: 2g strain Bb-12, 2g strain La-5, 3g inulin, 18g resistant dextrin, and starch as carrier. Adopt a one-step granulator to granulate all the mixed powders, pass through a 10-mesh sieve, and then use a fully automatic capsule filling machine to pack the granulated granules into capsules to obtain capsules (the specification is 0.5g / capsule of content).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com