Preparation method and application of a filter additive for improving cigarette smoking comfort

A technology of additives and cigarette filter rods, which is applied in applications, e-liquid filter elements, tobacco, etc., to achieve the effect of easy realization, improvement of throat coolness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

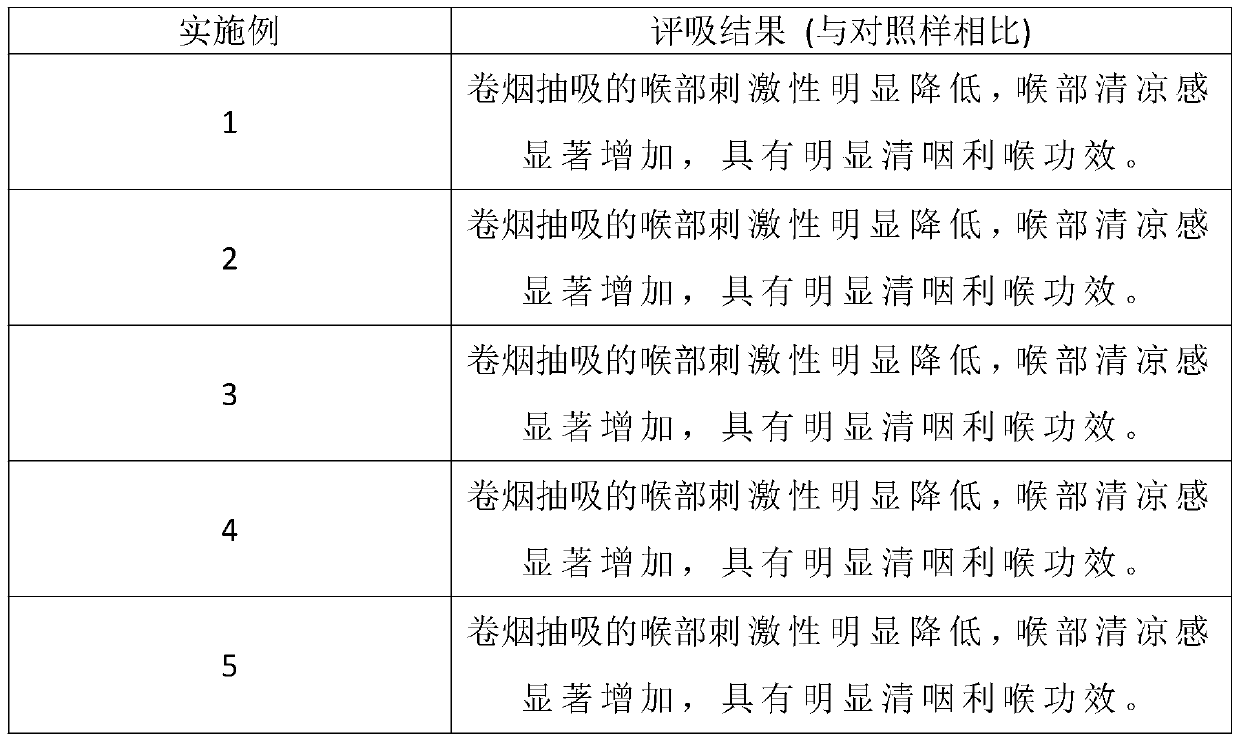

Examples

Embodiment 1

[0023] The whole plant of Dongbasil was washed, dried at 70°C and crushed to 80 mesh. Take the ground perilla powder, use dimethyl ether as the subcritical extractant, glycerol triacetate as the entrainer, and carry out subcritical extraction at a temperature of 30°C and an extraction pressure of 2.5Mpa; the extractant dimethyl The amount of ether is 10 times of the weight of Dong Perilla. The amount of triacetin used as an entraining agent is 4 times the weight of Dong Shiso. After the extraction is completed, the extraction mixture enters the separation tank, and the extraction solvent is separated by the principle of vacuum evaporation to obtain the glycerol triacetate extract of the eastern perilla. After recovery of dimethyl ether, the triacetin extract of Perilla triacetin was diluted 10 times with glycerol triacetate to make it fully dissolved, cooled to room temperature, transferred to -15°C refrigerator for 10 hours, and filtered to separate the clear liquid. Qingye...

Embodiment 2

[0025] The whole plant of Dongbasil was washed, dried at 75°C and crushed to 90 mesh. Take the ground perilla powder, use dimethyl ether as the subcritical extractant, glycerol triacetate as the entrainer, and carry out subcritical extraction at a temperature of 25°C and an extraction pressure of 2.8Mpa; the extractant dimethyl The amount of ether is 12 times of the weight of Eastern perilla. The amount of triacetin used as an entrainer is 5 times the weight of Dong Shiso. After the extraction is completed, the extraction mixture enters the separation tank, and the extraction solvent is separated by the principle of vacuum evaporation to obtain the glycerol triacetate extract of the eastern perilla. After recovery of dimethyl ether, the triacetin extract of Perilla triacetin was diluted 10 times with glycerol triacetate to make it fully dissolved, then cooled to room temperature, transferred to -18°C refrigerator for 10 hours, and filtered to separate the clear liquid. Qingy...

Embodiment 3

[0027] The whole plant of Dongbasil was washed, dried at 78°C and crushed to 95 mesh. Take the ground perilla powder, use dimethyl ether as the subcritical extractant, glycerol triacetate as the entrainer, and carry out subcritical extraction at a temperature of 28°C and an extraction pressure of 2.9Mpa; the extractant dimethyl The amount of ether is 15 times of the weight of Eastern perilla. The amount of triacetin used as an entrainer is 5 times the weight of Dong Shiso. After the extraction is completed, the extraction mixture enters the separation tank, and the extraction solvent is separated by the principle of vacuum evaporation to obtain the glycerol triacetate extract of the eastern perilla. After recovery of dimethyl ether, the triacetin extract of Perilla triacetin was diluted 8 times with glycerol triacetate to make it fully dissolved, then cooled to room temperature, transferred to -20°C for 8 hours, and centrifuged to separate the clear liquid. Used as a plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com