Purple sweet potato and purple potato beverage and preparation method thereof

A purple potato and purple potato technology, applied in the direction of food ingredients as taste improvers, food science, application, etc., can solve the problems of unacceptable taste, single product form, and monotonous taste, so as to achieve the best taste and flavor and satisfy the human body demand, colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Peel the washed purple potatoes and purple potatoes, cut into thin slices of about 0.5-2 cm, and steam at 100°C for 3-6 minutes to kill enzymes. Crush the enzyme-inactivated raw materials, cook them for 20-40 minutes to make them gelatinized thoroughly, add water to the mashed potatoes that have been gelatinized completely, and use a colloid mill to refine them to obtain a slurry.

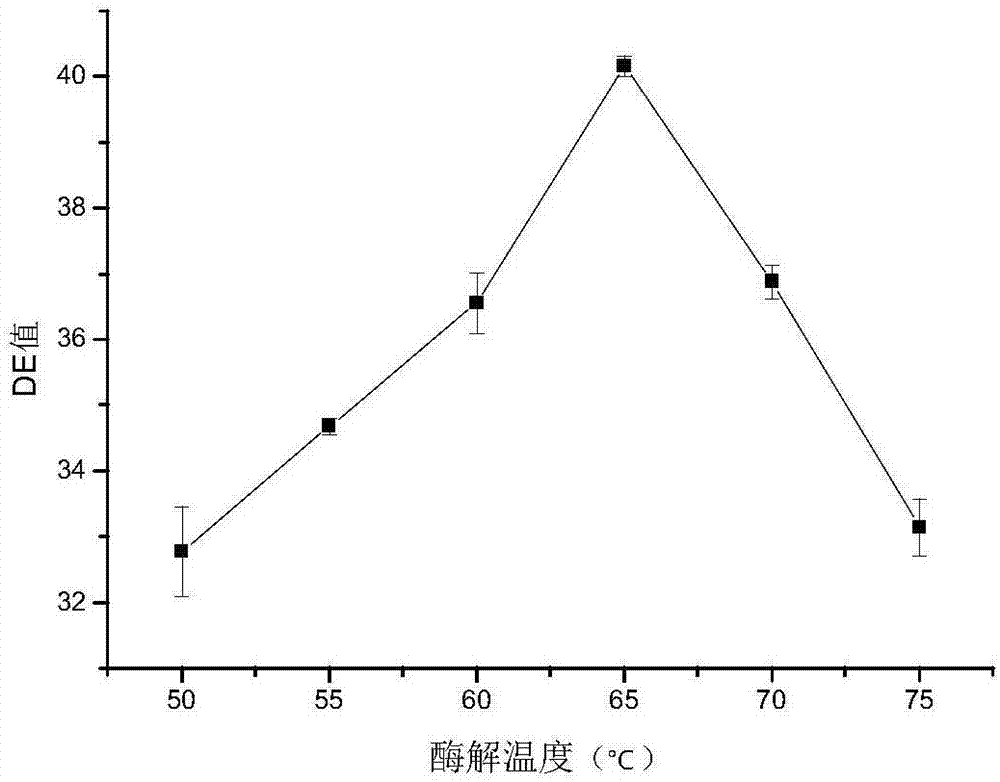

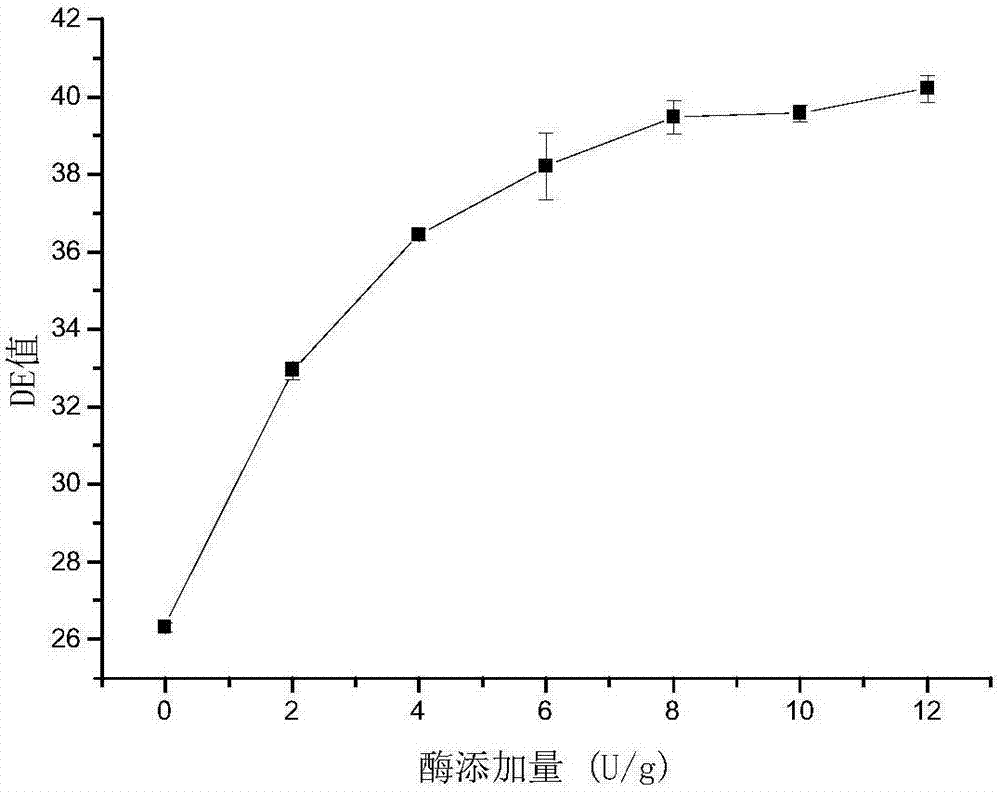

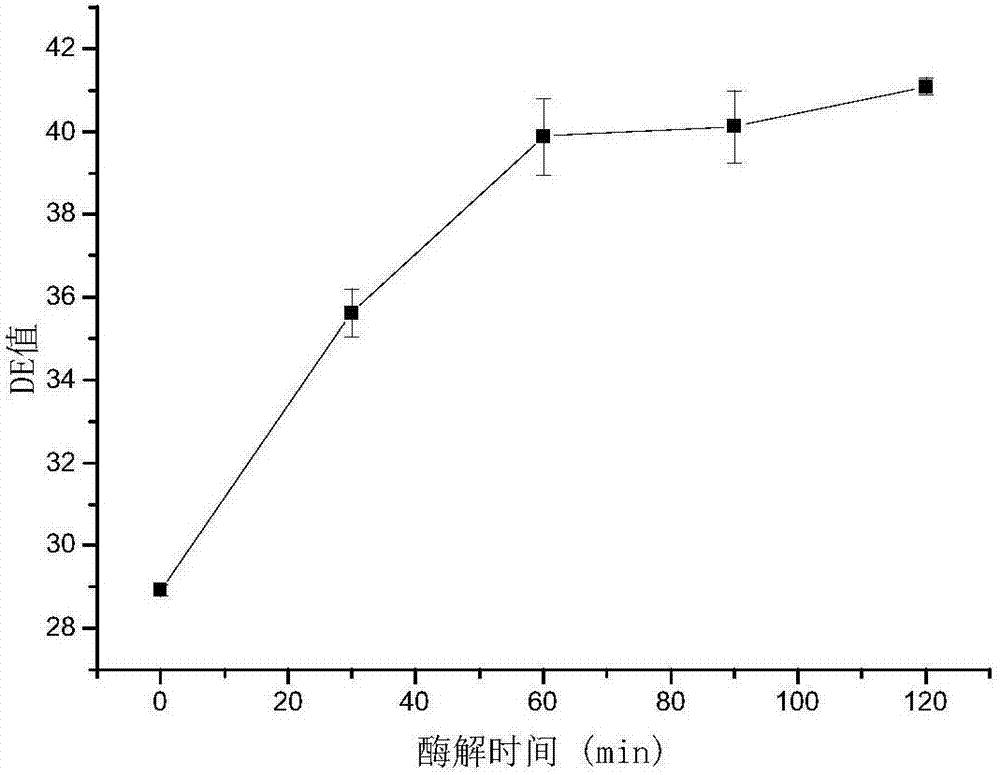

[0025] Add α-amylase to the slurry for enzymatic hydrolysis. Taking the enzymatic hydrolysis temperature, the amount of α-amylase added, and the enzymatic hydrolysis time as the abscissa and the DE value as the ordinate, draw the change curve of the DE value, such as figure 1 , 2 , 3 shown. According to the graph, select a better range of values: the enzymolysis temperature is 60-70°C, the amount of α-amylase added is 6-8U / g, and the enzymolysis time is 40-60min.

[0026] Add malic acid and citric acid to adjust the pH value to 4.2-4.5, and then add glucoamylase for saccharification. Tak...

Embodiment 2

[0028] In parts by weight, prepare 100 parts of purple sweet potato, 300 parts of purple potato, 1000 parts of water, 30 parts of sucrose, 1 part of citric acid and 0.7 part of malic acid.

[0029] Peel the washed purple potatoes and purple potatoes, cut into thin slices of about 0.5-2 cm, and steam at 100°C for 3-6 minutes to kill enzymes.

[0030] The raw materials after deactivation of the enzyme should be broken as much as possible, cooked for 20 minutes to make them gelatinized thoroughly, and the gelatinized potato mash was added with water to refine it with a colloid mill, and the speed of the colloid mill was 4000rmp / min.

[0031] Add α-amylase to the slurry for enzymatic hydrolysis, the amount of α-amylase added is 8U / g, the enzymolysis temperature is 60°C, and the enzymolysis time is 60min; then add glucoamylase for saccharification, and add malic acid at a mass ratio of 7:10 and citric acid to adjust the pH value to 4.2-4.5, the amount of glucoamylase added is 100U / ...

Embodiment 3

[0035] In parts by weight, prepare 300 parts of purple potato, 100 parts of purple potato, 1600 parts of water, 100 parts of sucrose, 1 part of citric acid, 0.7 part of malic acid, 0.2 part of gellan gum, 0.1 part of xanthan gum, carboxymethyl fiber Sodium 0.1 part.

[0036] Peel the washed purple potatoes and purple potatoes, cut into 1cm slices, and steam at 100°C for 4 minutes to kill enzymes.

[0037] The raw materials after deactivation of enzymes should be broken as much as possible, steamed for 20 minutes to make them completely gelatinized, and the fully gelatinized mashed potatoes should be refined with 4 times of hydrocolloid grinding, and the speed of the colloid mill should be 8000rmp / min.

[0038] Add α-amylase for enzymatic hydrolysis, the amount of α-amylase added is 6U / g, the enzymatic hydrolysis temperature is 65°C, and the enzymatic hydrolysis time is 40min; then add glucoamylase for saccharification, add malic acid and citric acid at a mass ratio of 7:10 Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com