Control system for electrically heated boiler

A boiler control and electric heating technology, which is applied in control systems, fluid heaters, lighting and heating equipment, etc., can solve the problems of inflexible control methods and low intelligence, and achieve intuitive display effects, high intelligence, and The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

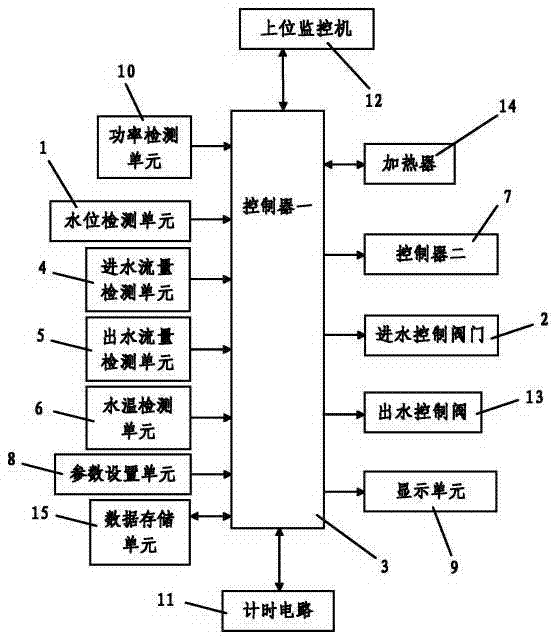

[0024] As shown in Figure 1, the present invention comprises the water level detection unit 1 that real-time detection is carried out to the internal water level of the monitored boiler, the water inflow control valve 2 that is installed on the water inlet pipe of the monitored boiler, the internal water of the described water inlet pipe Inlet flow detection unit 4 for real-time detection of flow, outlet flow detection unit 5 for real-time detection of water flow inside the outlet pipe of the monitored boiler, water temperature detection unit 6 for real-time detection of water temperature inside the monitored boiler, and outlet water flow A controller that automatically adjusts the valve opening of the water inlet control valve 2 according to the difference between the detection results of the detection unit 5 and the water inlet flow detection unit 4. 3. According to the detection of the water outlet flow detection unit 5 As a result, the controller 2 7 that analyzes the incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com