Polyester composite yarn and densely stained fabric made of polyester composite yarn

A composite yarn and polyester technology, which is applied in the field of concentrated dyeing fabrics, can solve the problems of low sheath filament monofilament fineness, affecting the fabric's dense dyeing, etc., and achieve the effects of strong dye absorption rate, remarkable deep dyeing effect, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

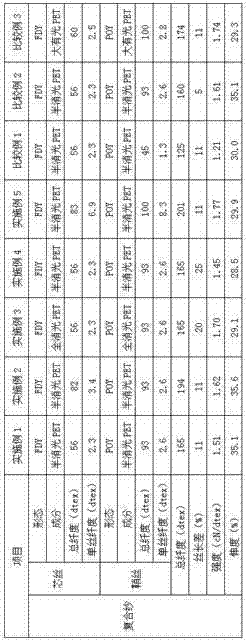

Embodiment 1

[0045]56dtex-24f-semi-dull PET-FDY is selected as the core yarn, 93dtex-36f-semi-dull PET-POY is used as the sheath yarn, and fed into the air deformation nozzle. The processing conditions are as follows: core yarn overfeed rate 5%, sheath overfeed The 165dtex-60f-PET composite yarn of the present invention was obtained at a processing rate of 16%, a processing speed of 350m / min, and a hot plate temperature of 180°C. The strength was 1.51cN / dtex, and the elongation was 35.1%. The parameters are shown in Table 1.

Embodiment 2

[0047] 82dtex-24f-semi-dull PET-FDY is selected as the core yarn, 93dtex-36f-semi-dull PET-POY is used as the sheath yarn, and fed into the air deformation nozzle. The processing conditions are as follows: core yarn overfeed rate 5%, sheath overfeed The 194dtex-60f-PET composite yarn of the present invention was obtained at a processing rate of 16%, a processing speed of 350m / min, and a hot plate temperature of 180°C. The strength was 1.62cN / dtex, and the elongation was 35.6%. The parameters are shown in Table 1.

Embodiment 3

[0049] 56dtex-24f-full-dull high-shrinkage PET-FDY (boiling water shrinkage 25%) is selected as the core yarn, 93dtex-36f-full-dull PET-POY is used as the sheath yarn, and fed into the air deformation nozzle. The processing conditions are as follows: Feed rate 5%, sheath yarn overfeed rate 25%, processing speed 350m / min, hot plate temperature 180 ℃, make 165dtex-60f-PET composite yarn of the present invention, its strength 1.70cN / tex, elongation is 29.1% , the parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com