Method for polymerization of diglycol and ethylene oxide

A technology for ethylene oxide and polymerization, applied in the direction of chemical recovery, etc., can solve the problems of difficult recovery and utilization of rectification substrates, cumbersome separation and purification steps, waste of resources and environment, etc., and achieves reduction of neutralization process, easy removal, The effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

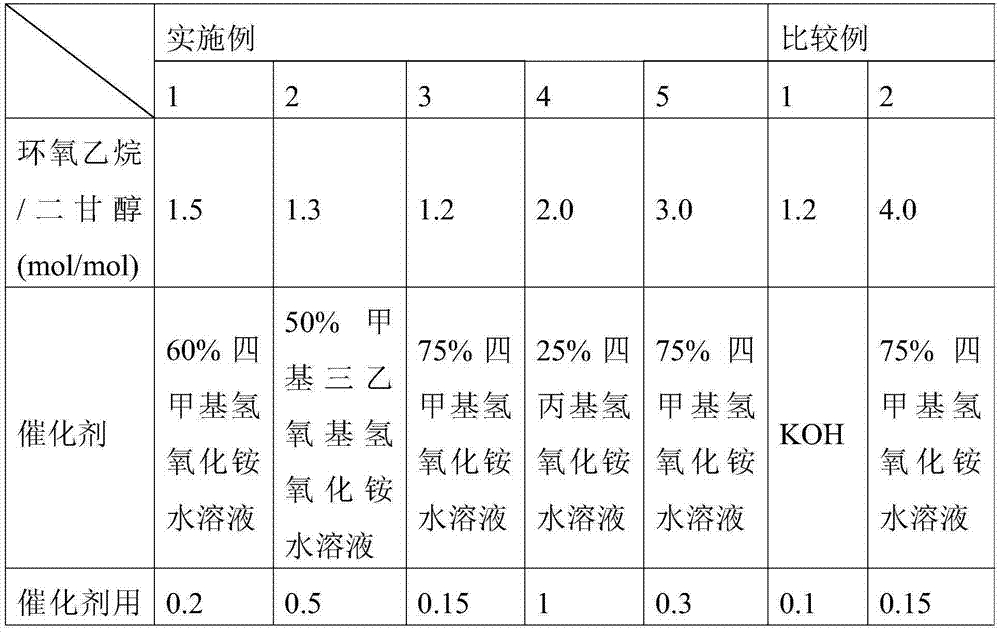

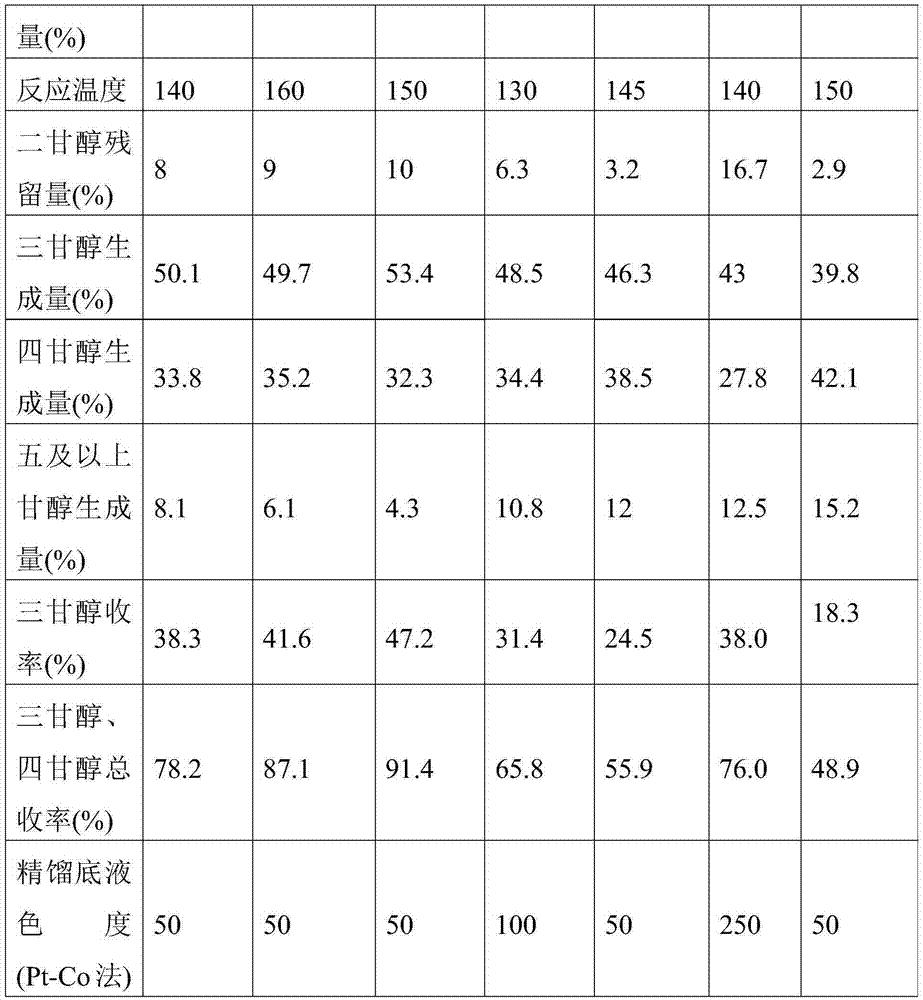

Embodiment 1

[0031] (1) Drop into 300g diethylene glycol, 1g 75% tetramethylammonium hydroxide aqueous solution in the dry 2L pressure reaction kettle, seal the reaction kettle; Replace the air in the reaction kettle with nitrogen 3 times, start stirring; be heated up to 100 ℃, Slowly add 187g of ethylene oxide to carry out the copolymerization reaction; wherein, by controlling the adding speed of ethylene oxide, the reaction pressure is kept at 0.3MPa, and the reaction temperature is kept at 140°C for 3 hours; after the ethylene oxide is completely introduced, Aging at 140°C for 30 minutes, and then degassing at -0.09MPa for 50 minutes to obtain a colorless and transparent triethylene glycol mixture. The content (weight percentage) of each component was analyzed by gas chromatography, and the results are listed in Table 1. .

[0032](2) Move the triethylene glycol mixture into the rectification tower, heat up, and distill diethylene glycol under reduced pressure at 104°C / 0.66KPa (170°C at...

Embodiment 2

[0035] (1) Put 300g of diethylene glycol and 2.3g of 50% methyltriethoxyammonium hydroxide aqueous solution into a dry 2L pressure reactor, seal the reactor; replace the air in the reactor with nitrogen for 3 times, start stirring; heat up To 100°C, slowly add 162g of ethylene oxide to carry out the copolymerization reaction; wherein, by controlling the adding speed of ethylene oxide to keep the reaction pressure at 0.35MPa, the reaction temperature is kept at 160°C for 6h; the ethylene oxide is completely After passing through, mature at 160°C for 30min, and then degas at -0.09MPa for 50min to obtain a colorless and transparent triethylene glycol mixture. Analyze the content of each component (percentage by weight) by gas chromatography, and the result is Listed in Table 1.

[0036] (2) Rectification process is with embodiment 1.

Embodiment 3

[0038] (1) Put 300g of diethylene glycol and 0.7g of 75% tetramethylammonium hydroxide aqueous solution into a dry 2L pressure reactor, seal the reactor; replace the air in the reactor with nitrogen for 3 times, start stirring; heat up to 100°C , slowly add 149g of ethylene oxide to carry out copolymerization reaction; wherein, by controlling the adding speed of ethylene oxide to keep the reaction pressure at 0.30MPa, the reaction temperature is kept at 150°C for 4h; after the ethylene oxide is completely introduced , matured at 150°C for 30min, and then degassed at -0.09MPa for 50min to obtain a colorless and transparent triethylene glycol mixture. The content of each component (weight percentage) was analyzed by gas chromatography, and the results are listed in the table. 1.

[0039] (2) Rectification process is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com