Zigzag push head for tube hydroforming

An internal high-pressure forming and zigzag technology, applied in the field of high-pressure forming molds, can solve the problems of radial expansion of the pipe diameter, increased feeding resistance of the pipe blank, wear of the mold or pusher, etc. Smooth, enhanced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

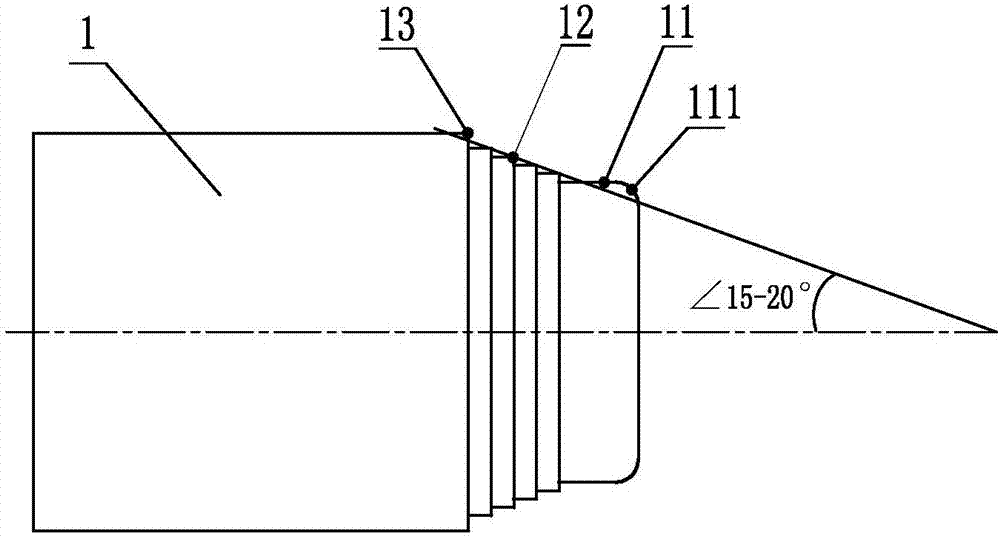

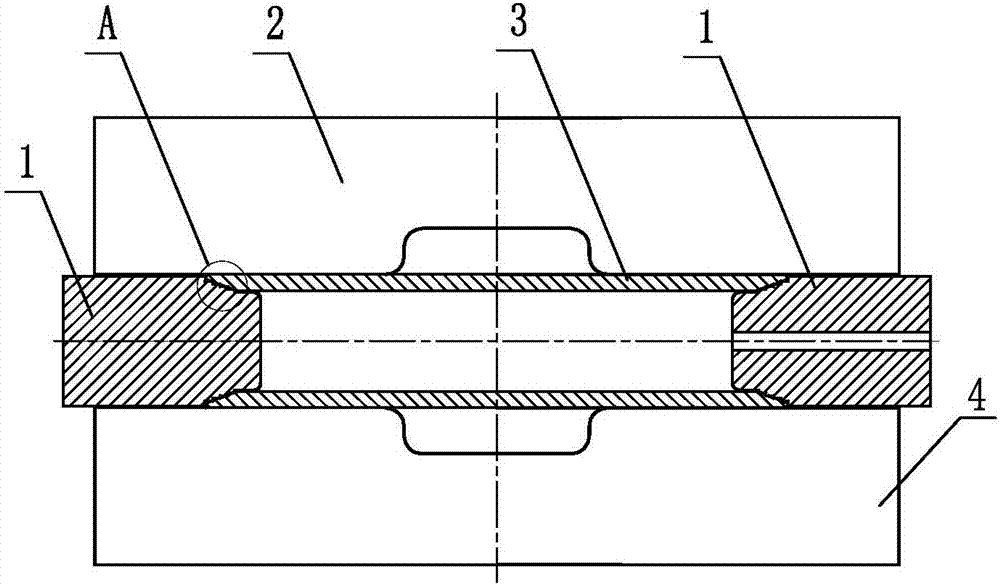

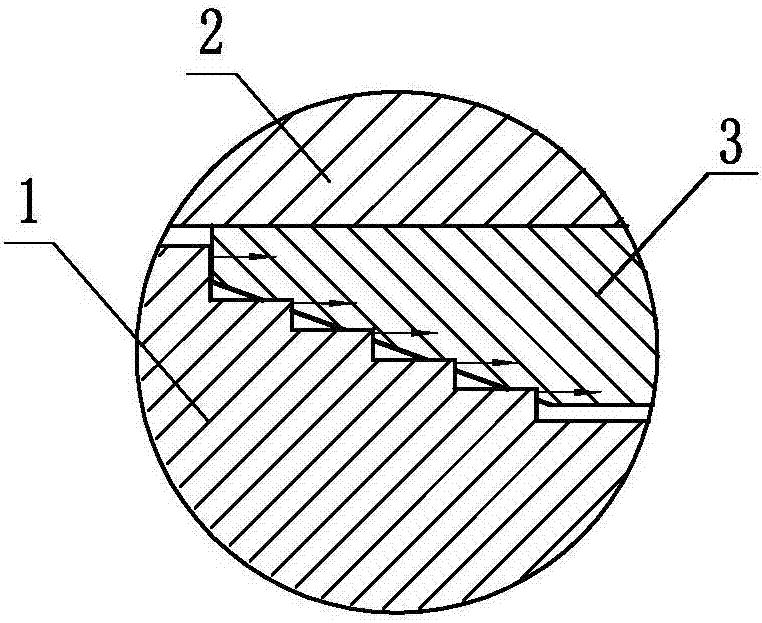

[0024] as attached figure 1 As shown, a zigzag push head structure for high pressure forming in pipes includes a push head body 1, the front end of the push head body is a zigzag seal head, including a guide head 11 and a zigzag seal section, the guide The positive head is a cylinder with a diameter smaller than the inner diameter of the tube blank (in this embodiment, the diameter of the guiding section is 0.05-0.10mm smaller than the inner diameter of the tube blank, and the section length of the pushing head is 2-10mm, and the section length value is about the outer diameter of the tube blank. 10% but not less than 2mm, not more than 10mm), the front end of the push head is provided with a rounded corner 111; the rear end of the guide head cylinder is a zigzag sealing section, and the zigzag sealing section includes 4 stages with the same length and diameters step by step For circular bosses with increased equal difference (the circular bosses with the same length refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com