Computerized flat knitting machine yarn feeder and yarn detection control system thereof

A computerized flat knitting machine and yarn feeder technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as difficult control of yarn tension and easy yarn breakage, achieve uniform and stable yarn feeding, and prevent jamming , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

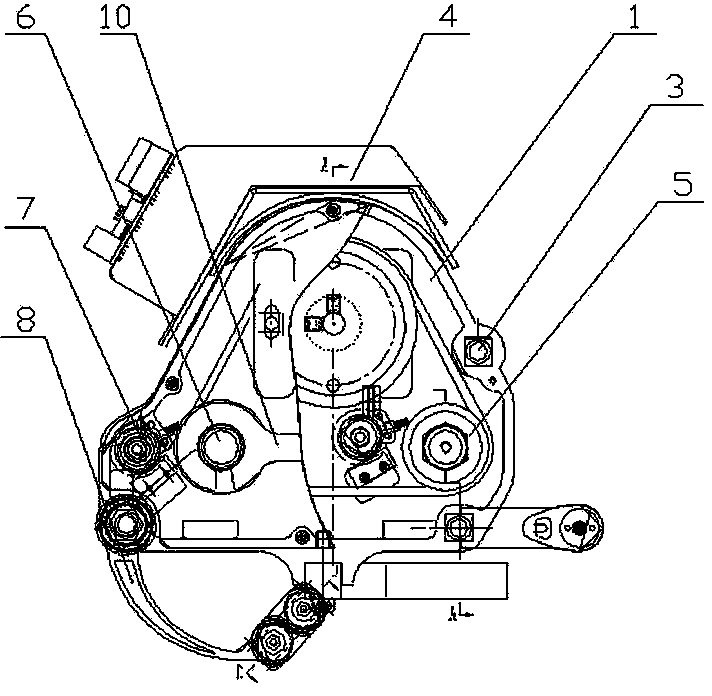

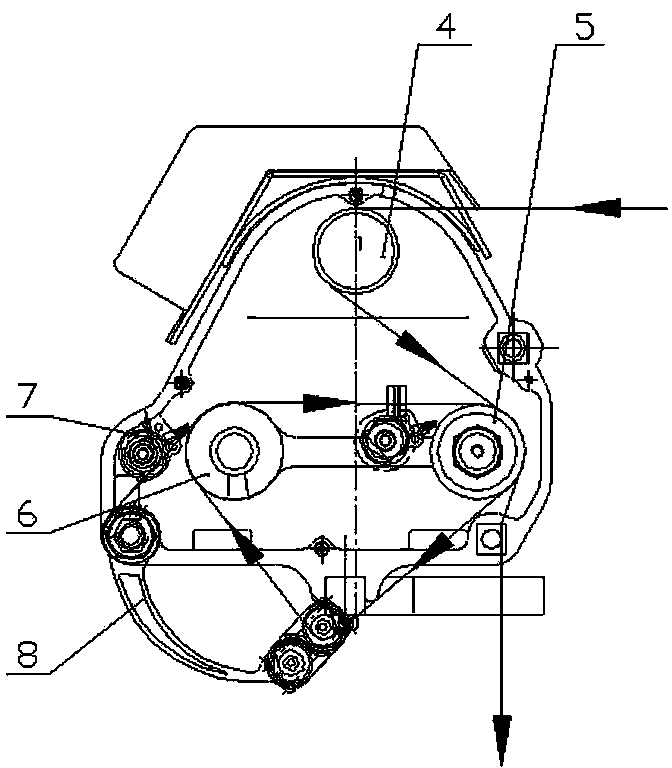

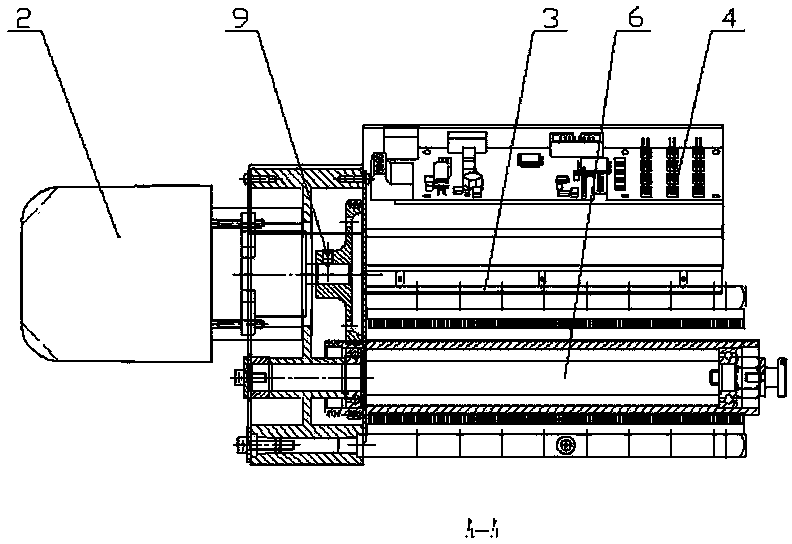

[0026] refer to Figure 1-Figure 9 , a computerized flat knitting machine yarn feeder, comprising a box body 1, a drive motor 2 installed outside the box body, a yarn guide rod 3, an encoder 4 assembled on the box body, a first yarn feed roller 5, a second yarn feeder Yarn roller 6, wax removal device 7 and adjustment device 8, and encoder 4 are connected to the computer, which can be used to measure the yarn speed and length, realize the stitch control of yarn feeding, and store data, suitable for different types of yarn, easy to use , the drive motor 2 drives the first yarn delivery roller 5 and the second yarn delivery roller 6 to rotate through the yarn delivery pulley 9, and the first yarn delivery roller 5 and the second yarn delivery roller 6 are connected by a connecting plate 10 and parallel Set, the side of the first yarn delivery roller 5 and the second yarn delivery roller 6 are respectively provided with a wax removal device 7, the wax removal device 7 is composed...

Embodiment 2

[0030] refer to Figure 1-Figure 9 , a computerized flat knitting machine yarn feeder, comprising a box body 1, a drive motor 2 installed outside the box body, a yarn guide rod 3, an encoder 4 assembled on the yarn guide rod, a first yarn feed roller 5, a second The yarn feeding roller 6, the wax removal device 7 and the adjustment device 8, the encoder 4 is connected with the computer, and can be used to measure the yarn speed and length, realize the stitch control of the yarn feeding, and store the data, which is suitable for different types of yarns. Conveniently, the drive motor 2 drives the first yarn delivery roller 5 and the second yarn delivery roller 6 to rotate through the yarn delivery pulley 9, and the first yarn delivery roller 5 and the second yarn delivery roller 6 are connected by a connecting plate 10, and Arranged in parallel, the sides of the first yarn delivery roller 5 and the second yarn delivery roller 6 are respectively provided with a wax removal devic...

Embodiment 3

[0033] refer to Figure 1-Figure 9 , a computerized flat knitting machine yarn feeder, comprising a box body 1, a drive motor 2 installed outside the box body, a yarn guide rod 3, an encoder 4 assembled on the box body, a first yarn feed roller 5, a second yarn feeder Yarn roller 6, wax removal device 7 and adjustment device 8, and encoder 4 are connected to the computer, which can be used to measure the yarn speed and length, realize the stitch control of yarn feeding, and store data, suitable for different types of yarn, easy to use , the drive motor 2 drives the first yarn delivery roller 5 and the second yarn delivery roller 6 to rotate through the yarn delivery pulley 9, and the first yarn delivery roller 5 and the second yarn delivery roller 6 are connected by a connecting plate 10 and parallel Set, the side of the first yarn delivery roller 5 and the second yarn delivery roller 6 are respectively provided with a wax removal device 7, the wax removal device 7 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com