Colorful solar cell piece, manufacturing method, cell module and PECVD device

A solar cell and color technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems that the color of the cell cannot be customized, the color regularity of the colored battery is poor, and the effect of the texture is uncontrollable, etc., and it is easy to achieve Implementation, color controllable, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

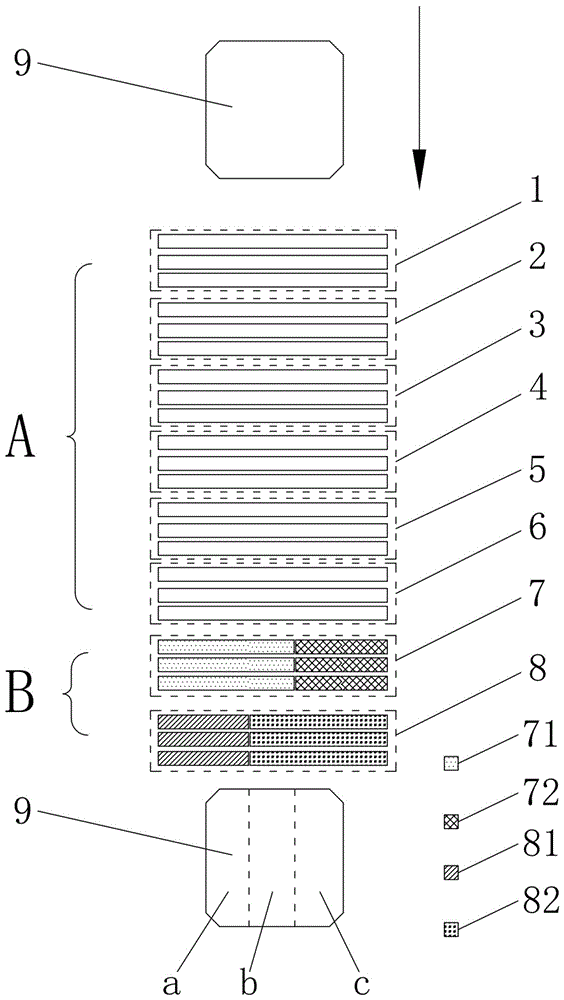

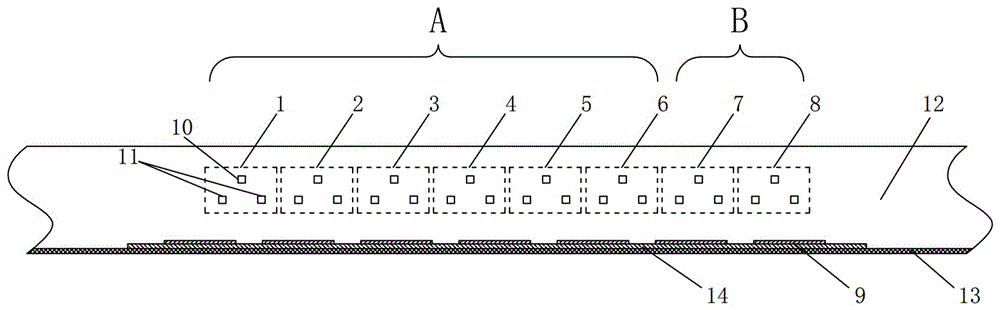

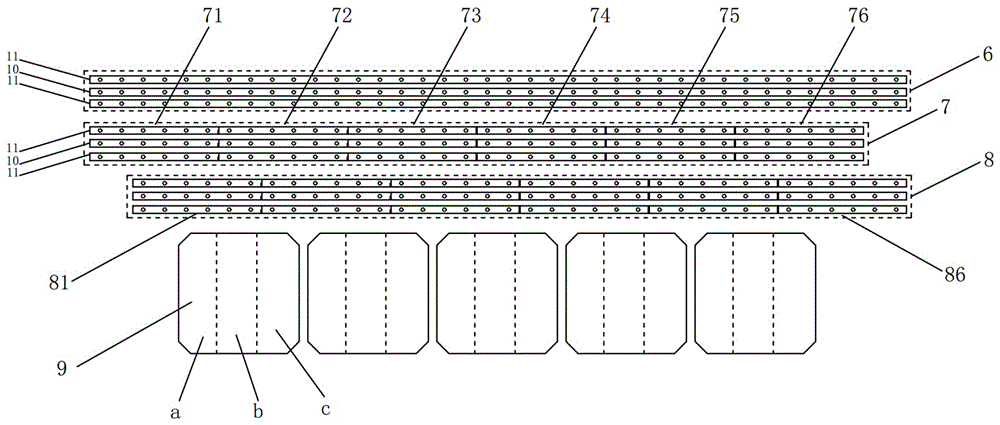

[0048] The invention provides a method for preparing a colored solar battery sheet. In the process of preparing a silicon nitride anti-reflection film on a silicon wafer, the chemical vapor deposition method is used to transport the silicon wafer through a deposition chamber with the front side facing upwards, and in the deposition chamber On the top of the silicon wafer, there are multiple groups of special gas pipelines arranged horizontally and perpendicular to the conveying direction along the silicon wafer conveying direction. The special gas pipelines are provided with uniformly distributed special gas holes for passing into the deposition chamber. Raw material gas, and deposit silicon nitride anti-reflection film on the front side of the silicon wafer.

[0049] The improvement of the preparation method of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com