Evaluation method of fabric pilling level based on visual attention mechanism

A visual attention mechanism and grade evaluation technology, applied in the field of grade evaluation, can solve the problems of affecting the evaluation effect, affecting the objective evaluation effect of pilling grade, and increasing the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

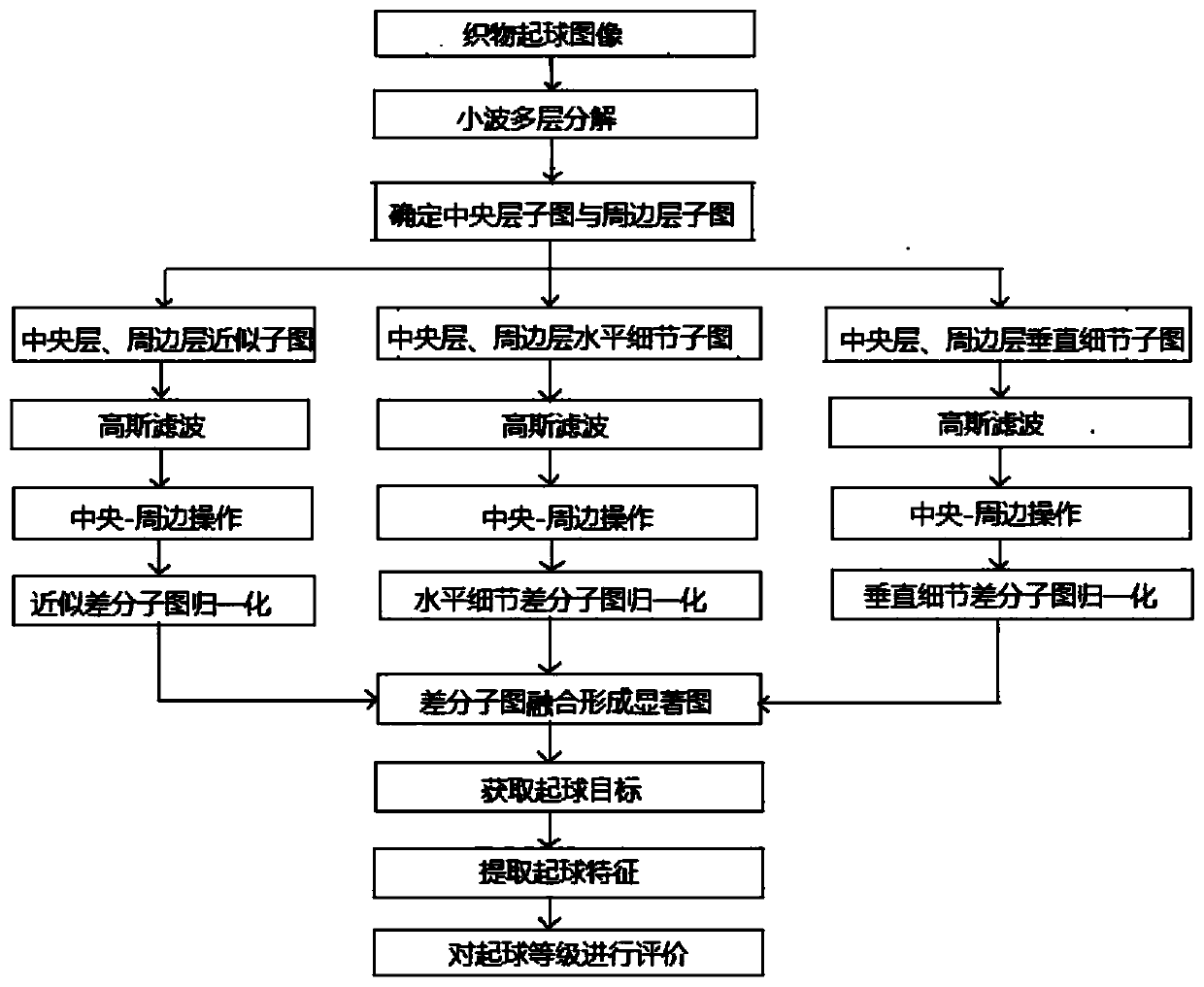

[0112] Such as figure 1 Shown, the fabric pilling grade evaluation method based on visual attention mechanism, comprises the following steps:

[0113] Step 1, collecting fabric pilling images;

[0114] Step 2, carry out wavelet multilayer decomposition to fabric pilling image:

[0115] Step 3, determine the central layer subgraph and the peripheral layer subgraph of the fabric pilling image;

[0116] Step 4, construct fabric pilling saliency map;

[0117] Step 5, obtaining the fabric pilling target;

[0118] Step 6, extracting fabric pilling features;

[0119] Step 7, evaluating the pilling level of the fabric;

[0120] In step 2, the specific steps for performing wavelet multi-layer decomposition on the fabric pilling image are:

[0121] Select DB2 wavelet to perform wavelet multi-layer static decomposition on the fabric pilling image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com